Special multifunctional grifola frondosa bed frame for experiment

A grifola frondosa, multi-functional technology, applied in the biological field, can solve the problems of inability to change and disassemble, increase the cost of experiments, and low utilization rate of equipment, so as to achieve convenient ventilation and sterilization, improve space turnover rate, and high utilization rate of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

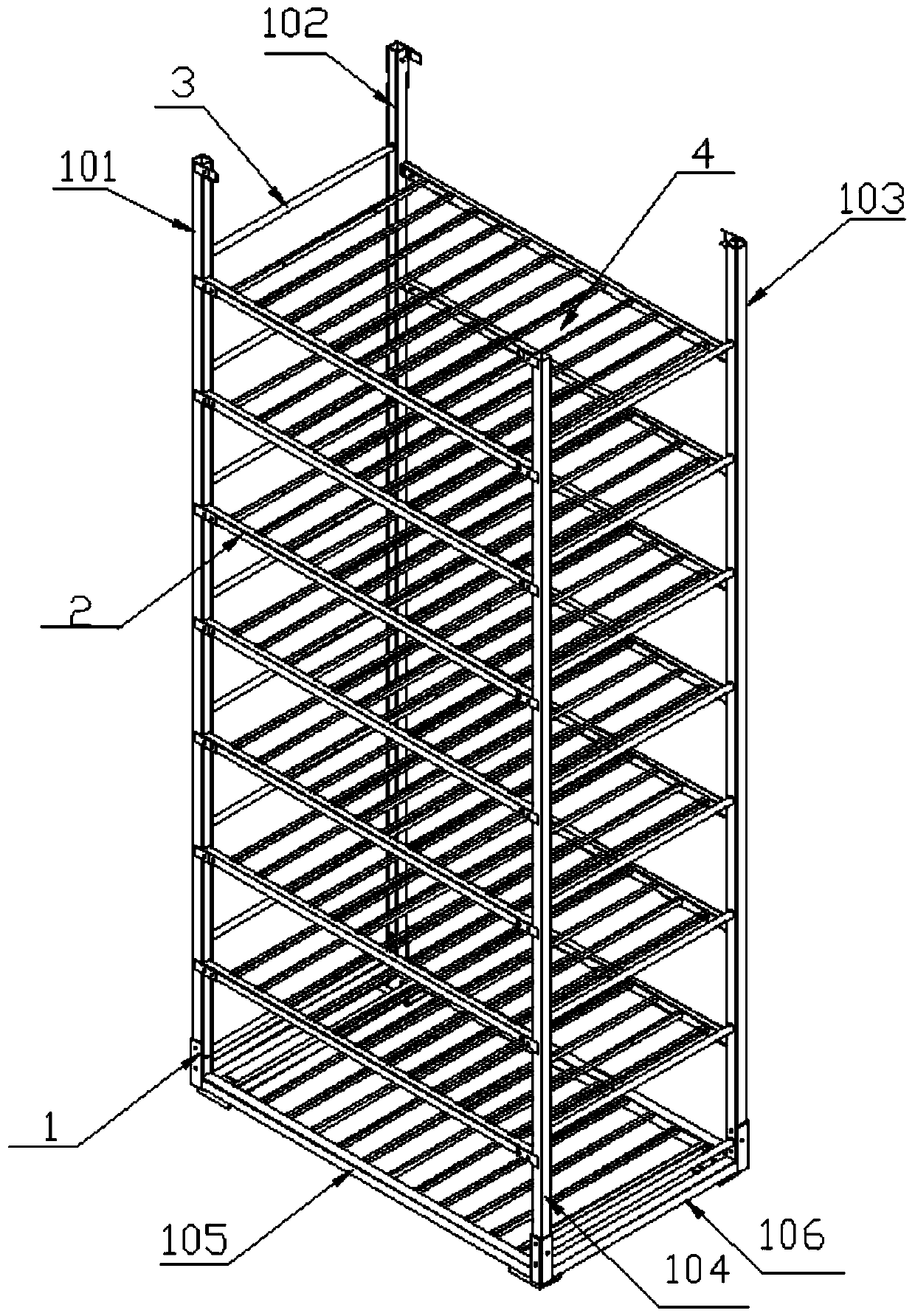

[0020] Embodiment one: if figure 1 As shown, a kind of Grifola frondosa multifunctional bed frame dedicated to the experiment includes a frame 1, a second horizontal load-bearing bar 2 and a second longitudinal load-bearing bar 3, and the frame 1 includes a first column 101, a second column 102, and a third column 103, the fourth column 104, the first transverse load-bearing bar 105 and the first longitudinal load-bearing bar 106, the bottom ends of the first column 101 and the fourth column 104, the second column 102 and the third column 103 are respectively provided with a first transverse Bearing bar 105, the first column 101 and the second column 102, the third column 103 and the bottom of the fourth column 104 are respectively provided with a first longitudinal load-bearing bar 106, the first horizontal load-bearing bar 105 vertically above is provided with several first Two horizontal load-bearing rods 2, the second horizontal load-bearing rod 2 is bolted to the frame 1,...

Embodiment 2

[0021] Embodiment 2: On the basis of Embodiment 1, four corners of the bottom of the frame 1 are respectively provided with a wheel to facilitate the movement of the bed frame.

Embodiment 3

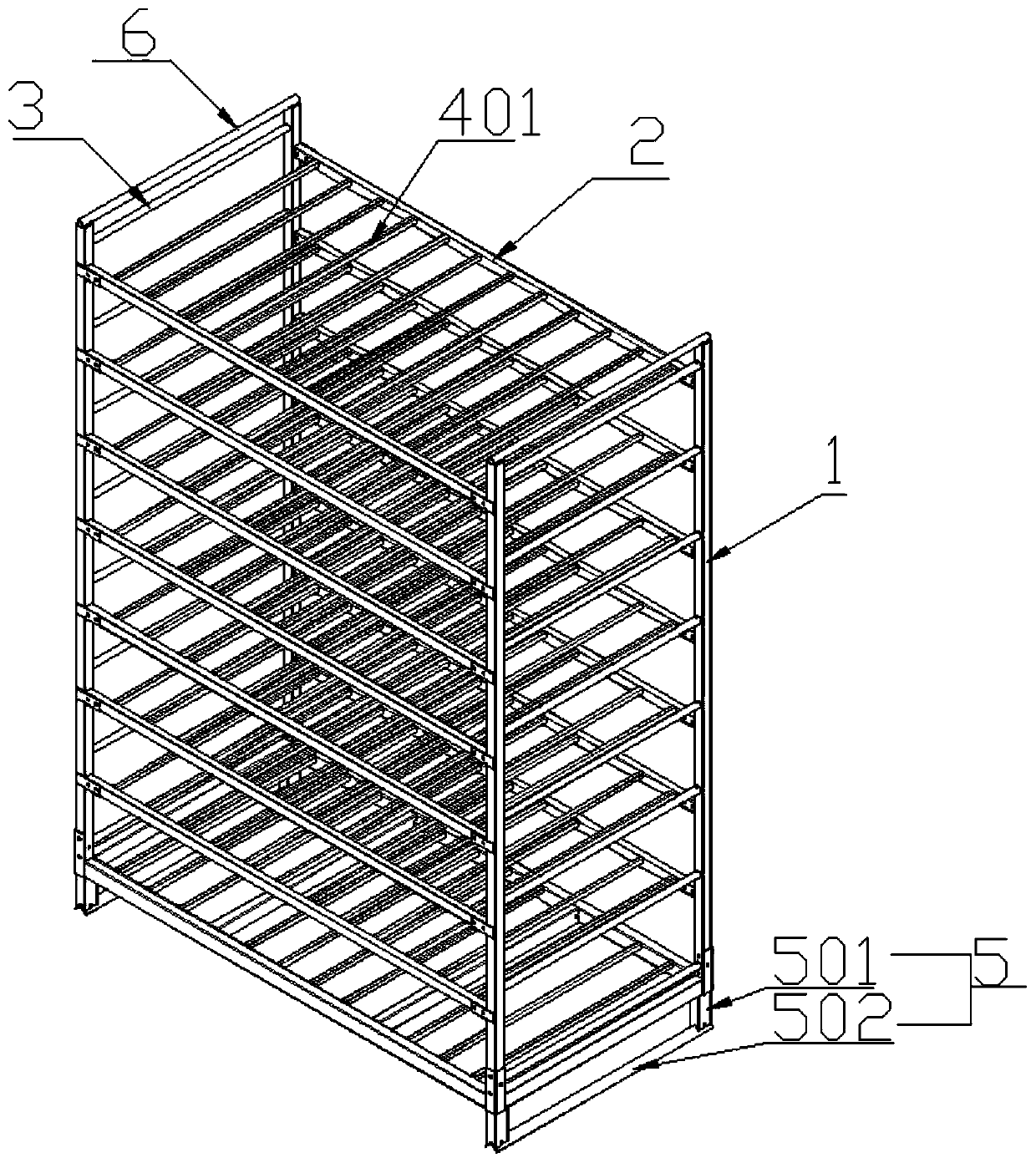

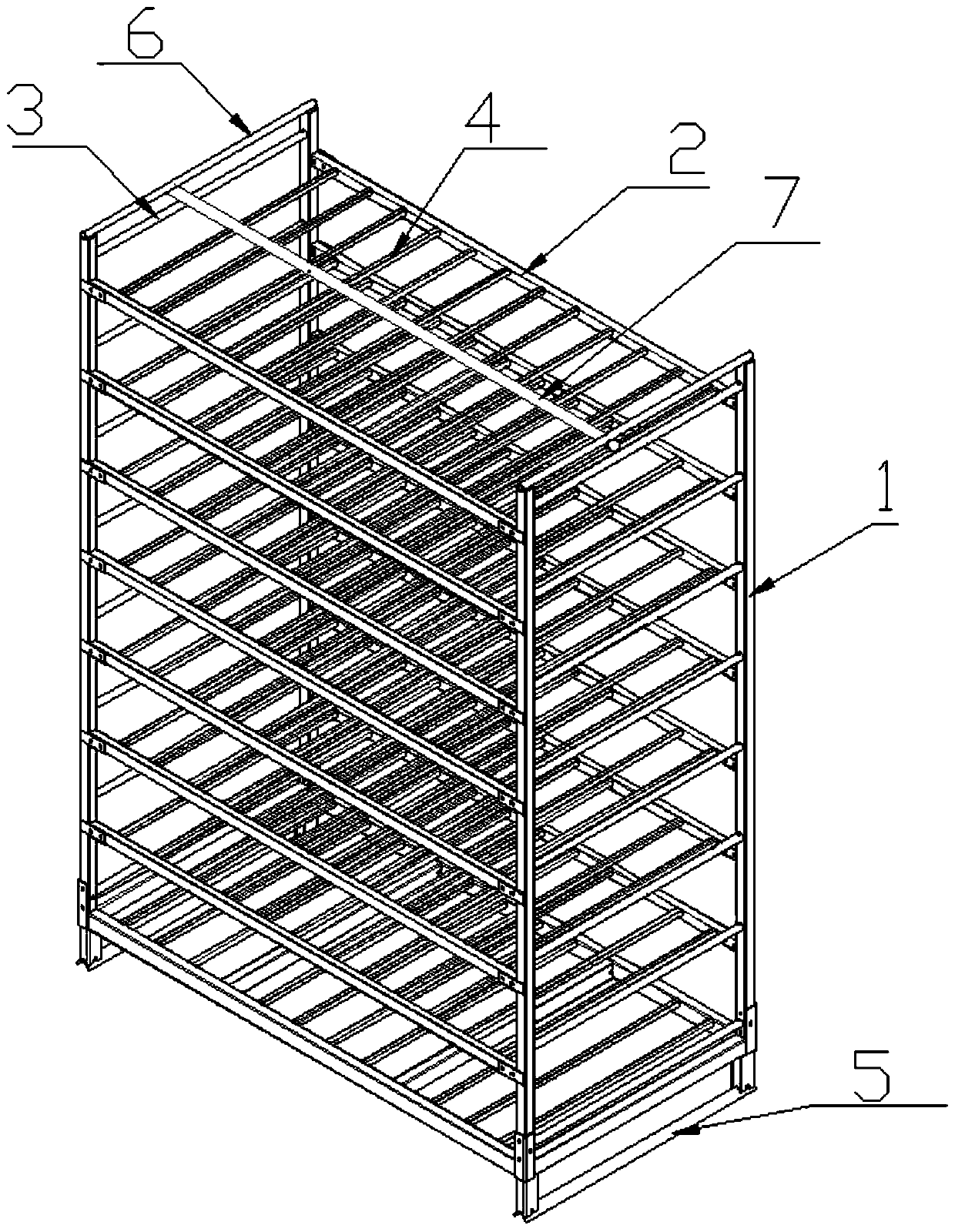

[0022] Embodiment three: as figure 2 As shown, on the basis of Embodiment 1, a bracket 5 is respectively provided at the bottom of the two first longitudinal load-bearing bars 106, and the bracket 5 includes a vertical bar 501 and a cross bar 502, and the two ends of the bottom of the first longitudinal load-bearing bar are fixedly connected respectively. There is a vertical bar 501, and the ends of the two vertical bars 501 away from the first longitudinal load-bearing bar 106 are respectively fixedly connected with the two ends of the cross bar 502. A third vertical load-bearing bar 6 is respectively provided with the top of the second column 102, the third column 103 and the fourth column 104, and the third vertical load-bearing bar 6 is a round tube, which cooperates with the angle iron at the bottom of the bracket 5, and can be used for multiple beds. rack stacked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com