Vacuum moisture regaining equipment based on threshing and redrying and process control method thereof

A technology of vacuum moisture resurgence and process control, which is applied in the fields of tobacco preparation, application, and tobacco. It can solve the problems of insufficient looseness of tobacco leaves, deterioration of sensory quality of tobacco leaves, and uneven moisture content of tobacco leaves, so as to increase the efficiency of leaf selection and reduce the risk of damage. Loss of aroma substances, reducing the effect of processing moisture regain intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objectives, technical solutions and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below to facilitate the understanding of the skilled person.

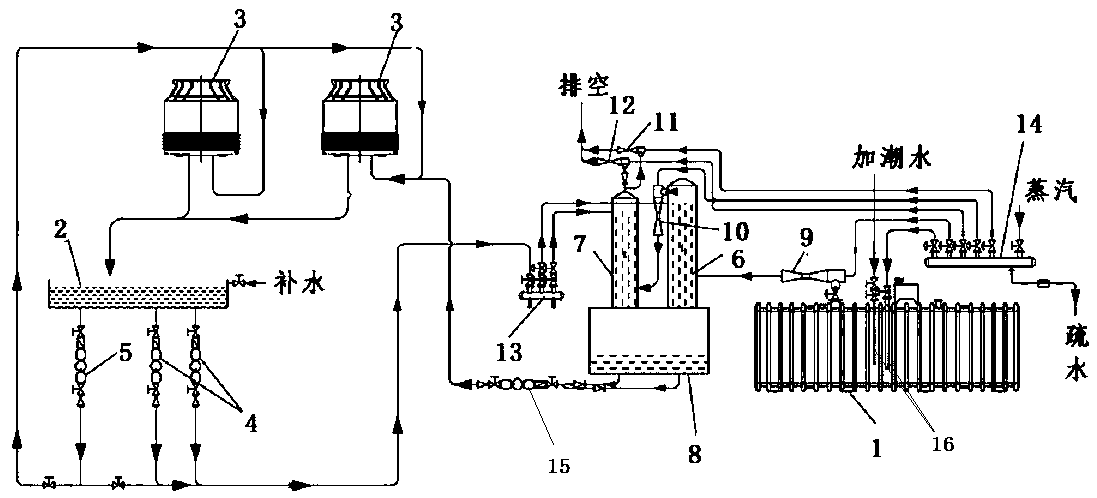

[0033] Such as figure 1 As shown, the vacuum moisture regaining equipment based on threshing and redrying includes a vacuum moisture regaining machine 1, a vacuum system, a humidification system, a steam distribution system 14, an air pressure and instrument system, a cooling-condensate discharge system, and an inlet and outlet system , Safety devices, etc.; cooling-condensate discharge system includes condensate water tank 8, cooling tower 3 and water tank 2, water supply pump 4, circulating water pumps 5, 15, pipelines and valves, etc.; vacuum system includes first-stage steam jet pump 9 , Two-stage steam injection pump 10, three-stage steam injection pump 11, starting steam injection pump 12, condensers 6 and 7, sub-cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com