Lost foam casting process monitoring system

A technology of lost foam casting and process monitoring, applied in foundry equipment, general control systems, control/regulation systems, etc., can solve the problems of product life cycle traceability, inability to monitor the casting process, and reduce the casting rate, so as to improve the whole life cycle. Effectiveness of cycle management, reduced risk of equipment failure, and increased casting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments. It should be clear to those skilled in the art that the specific implementation is only to help understand the present invention, and should not be regarded as a specific limitation on the present invention.

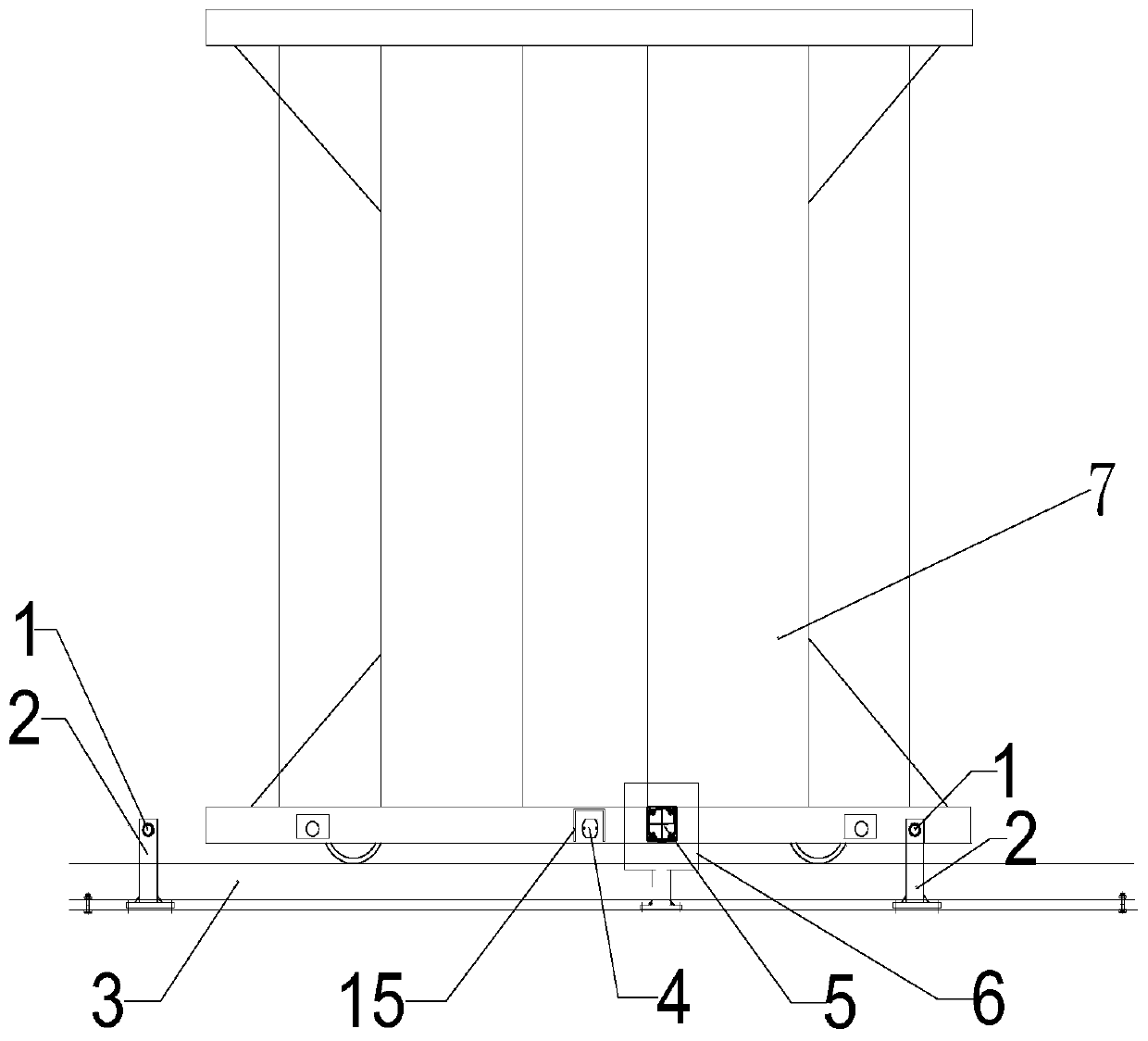

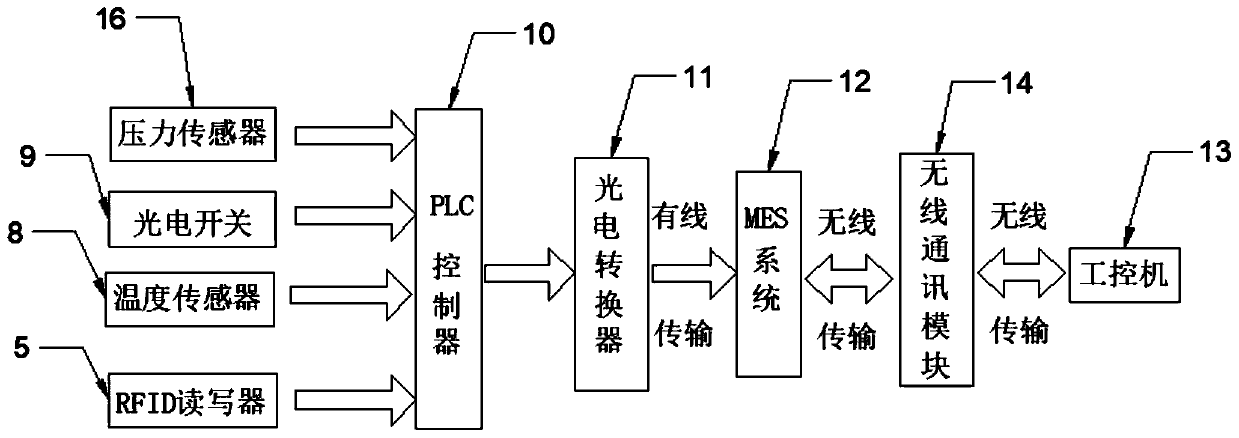

[0023] like Figure 1-2 As shown, a lost foam casting casting process monitoring system includes MES system 12, RFID tag 4, casting line RFID identification device, cooling line RFID identification device, sand box 7, casting information acquisition module, PLC controller 10, photoelectric converter 11. The wireless communication module 14 and the industrial computer 13, the MES system is used for the information management of the casting production process, and the RFID tag 4 is arranged in the middle of the trolley at the bottom of the sand box 7 for storing the information of the sand box; The casting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com