Electric nail gun

A nail gun and nail clip technology, which is applied in the field of electric nail guns, can solve the problems of heavy front end, low service life and high height of the whole machine, and achieve the effects of improving nailing efficiency, prolonging service life and high power utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

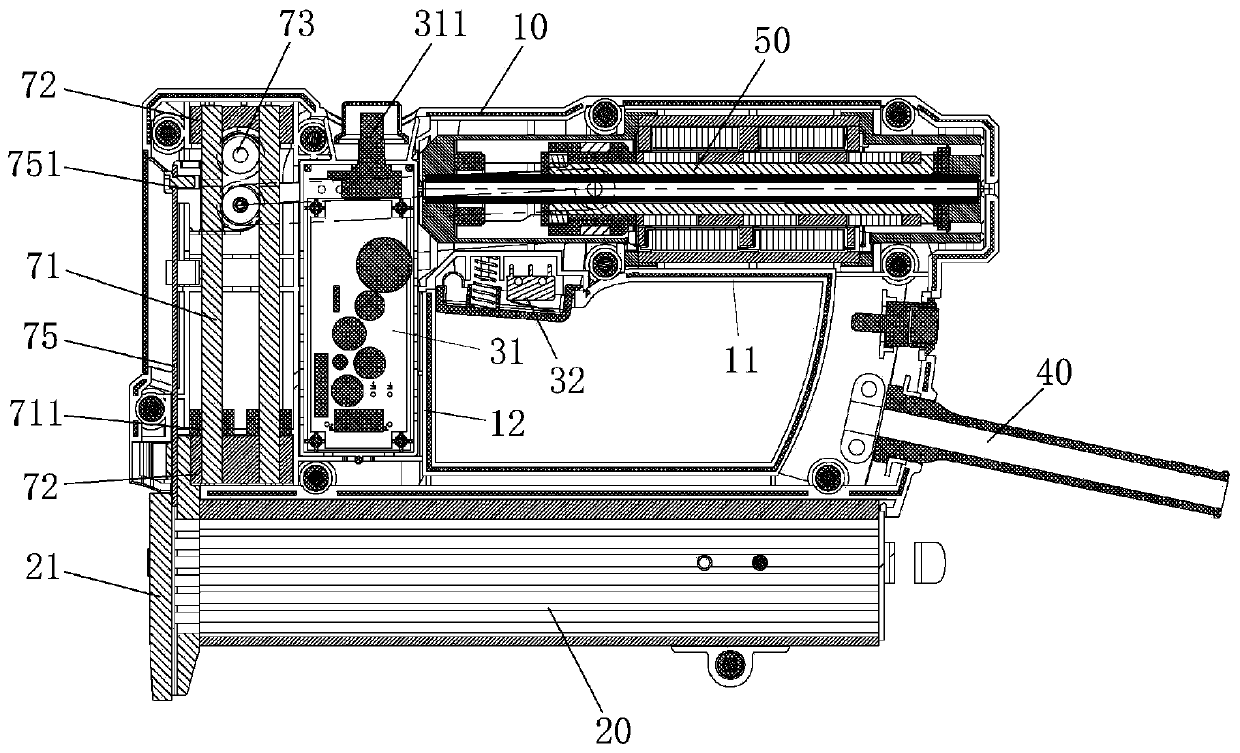

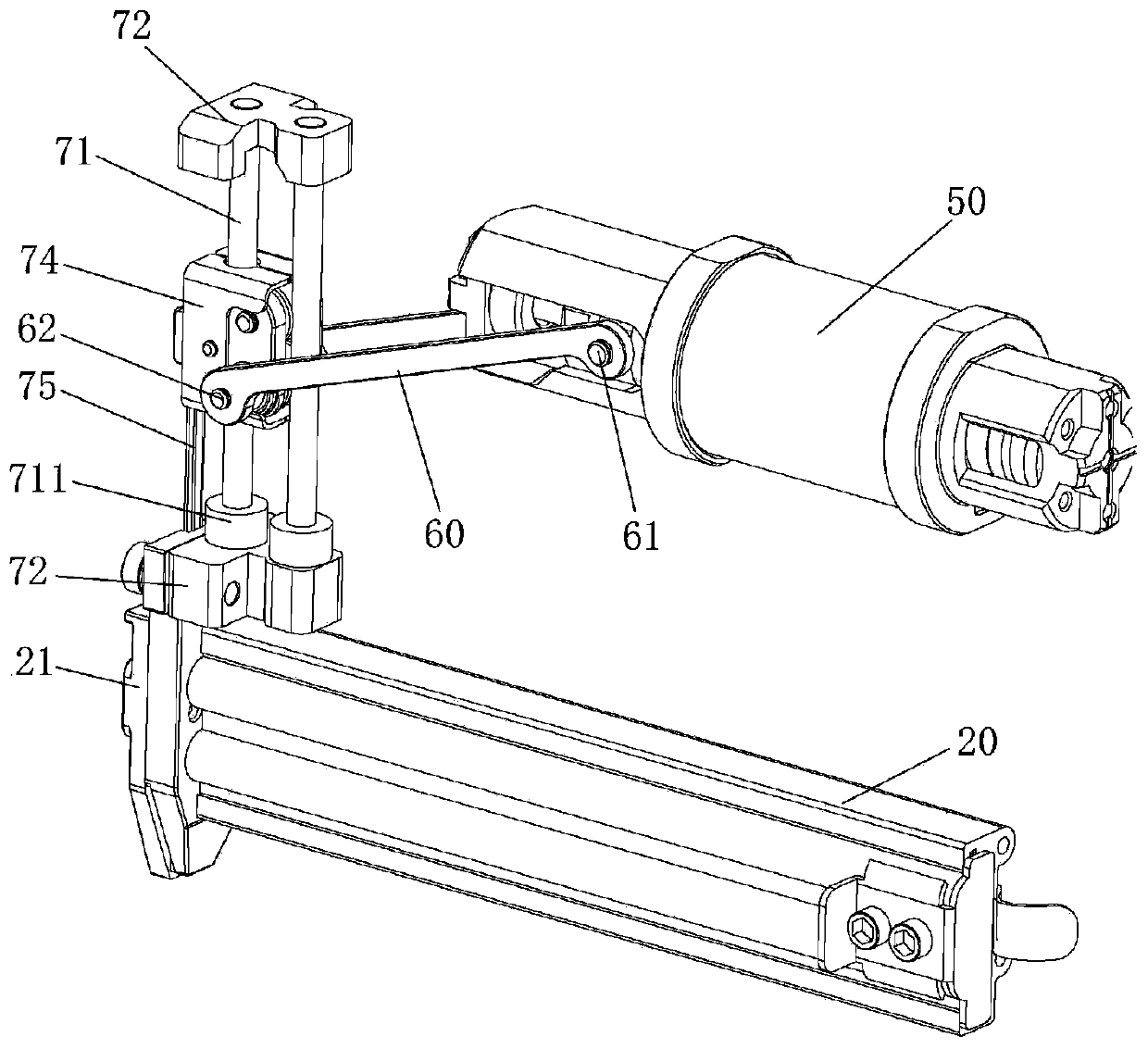

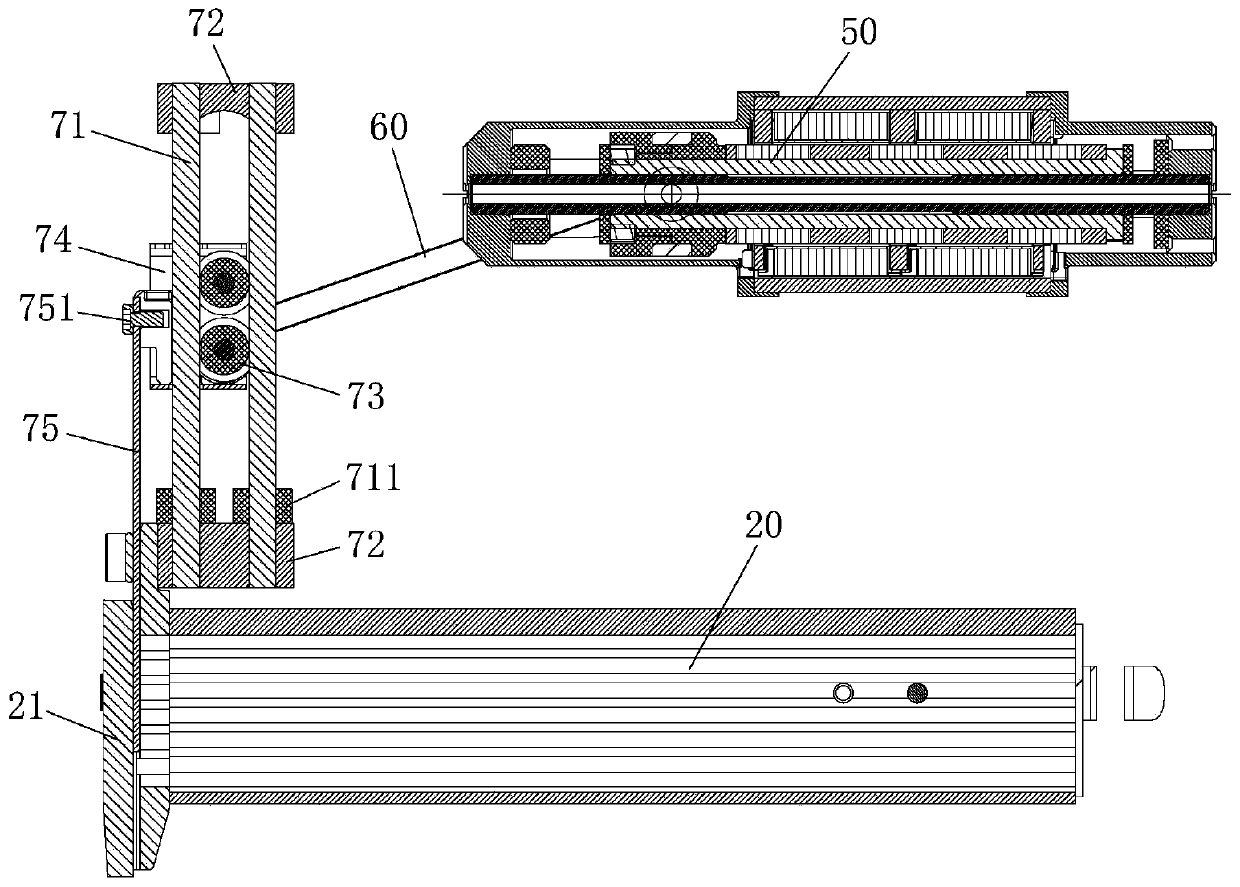

[0024] Such as Figure 1 to Figure 3 As shown, an electric nail gun of the present invention includes a casing 10, a nail clip 20 connected to the casing 10, a control assembly installed inside the casing 10, a linear motion drive unit 50, a connecting rod unit, and a linear motion actuator assembly . The casing 10 has a grip portion 11 . Inside the casing 10 is a receiving chamber 12 for installing internal components. The electric nail gun can be a DC electric nail gun or an AC electric nail gun. According to the actual situation, a battery is selectively installed inside the casing 10 or connected to the power connector 40 to supply power to the linear motion drive unit 50 . The battery is preferably disposed inside the storage chamber 12 .

[0025] Wherein, the linear motion driving unit 50 may adopt a linear motor, an electromagnet, etc., preferably a linear motor. The linear motion drive unit 50 moves in two directions. The linear motion actuator assembly and the li...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap