Underneath light roadbed structure passing operation bridge and design and construction methods thereof

A lightweight, subgrade technology, applied in the field of geotechnical engineering, can solve problems affecting the normal use of bridges, lateral displacement, and affecting the operating comfort of high-speed trains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

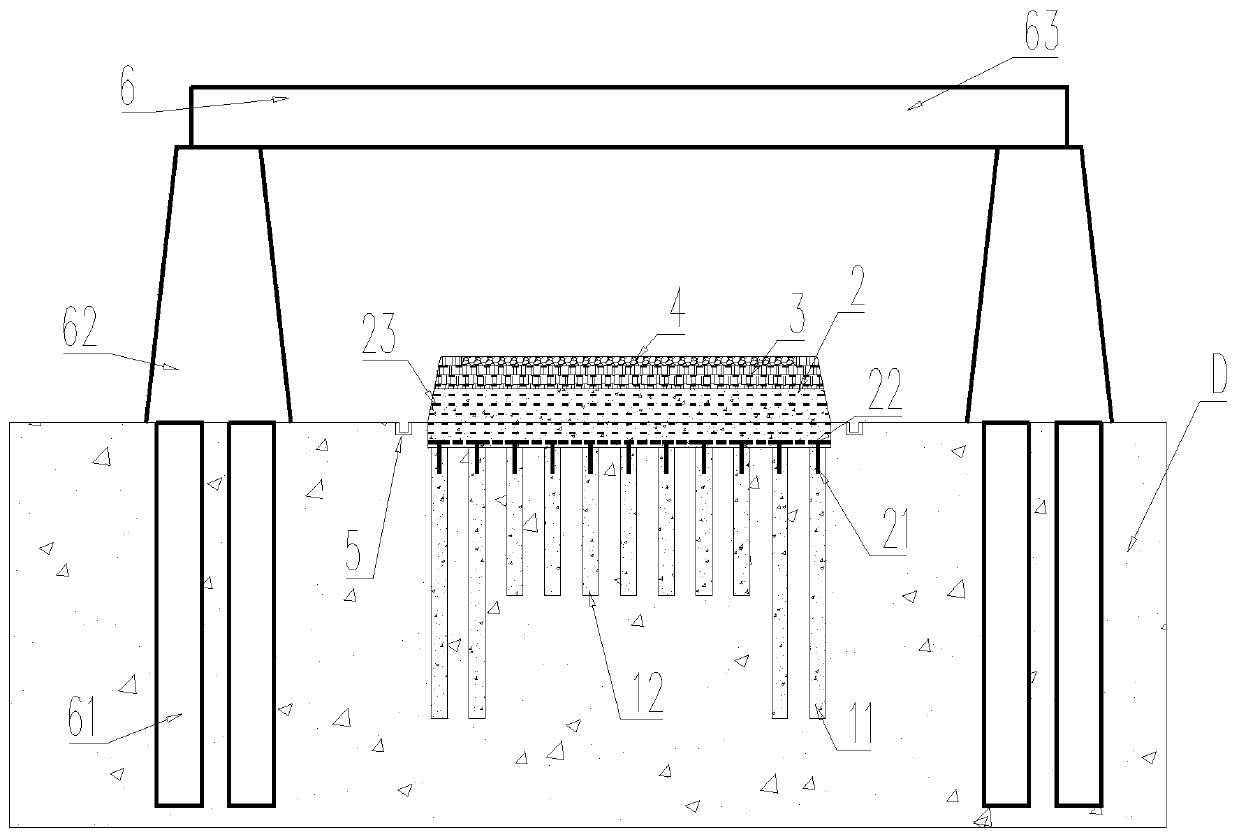

[0054] refer to figure 1 , the present invention underpasses the light subgrade structure of the operating bridge, double rows of long piles 11 are arranged at both ends of the subgrade transversely along the line longitudinally and adjacent to the foundation 61 of the bridge 6; short piles 12 are arranged at the bottom of the subgrade inside the long piles 11; The light body 2 is set on the top of the long pile 11 and the short pile 12; the U-shaped light groove 3 is set on the top of the light body 2; the soil filler 4 is filled in the U-shaped light groove 3; the drainage ditch 5. Set on both sides of the lightweight body 2 .

[0055] In the above scenario:

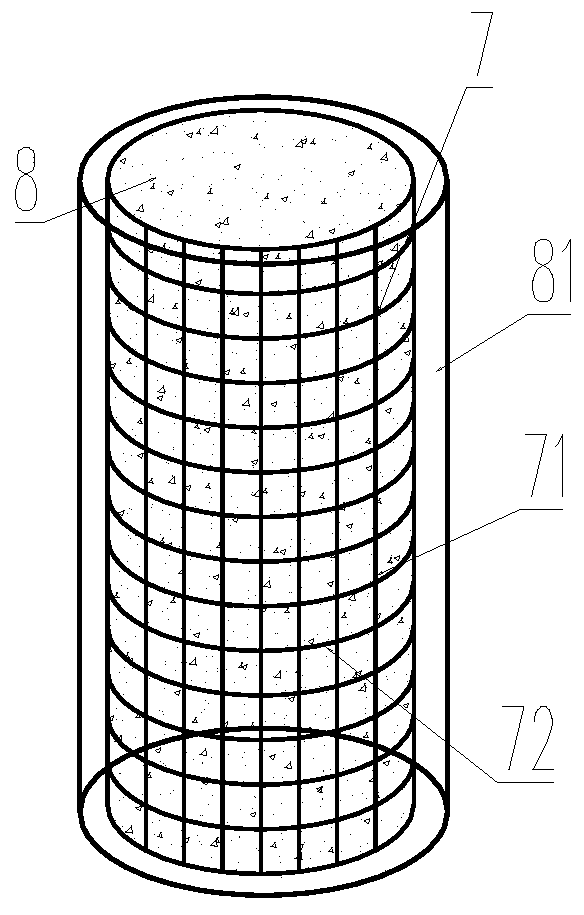

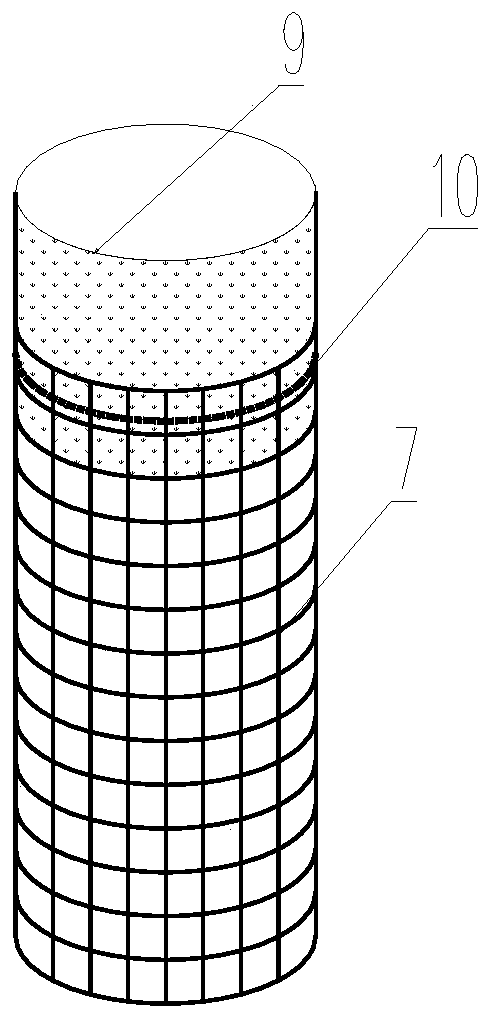

[0056] refer to figure 1 , 2 , 3, the long pile 11 and the short pile 12 all adopt the composite lightweight pile composed of the pile-forming lightweight body 8 and the composite reinforced cage 7 embedded in it, and the composite reinforced cage 7 is composed of vertical piles arranged at circumferential intervals...

Embodiment 2

[0083] Such as Figure 1-6 As shown, this embodiment specifically demonstrates the design method for the subgrade structure in construction, and the specific design process: a high-speed railway design speed is 300km / h (ballastless track), and the line spacing is 4.8m. In order to meet the design requirements of introducing a large hub, Subgrade engineering (height h=3.5m, width B=14.6m) needs to be built under the operating bridge 6, and the stratum in the section is silty clay. The design intends to adopt the light subgrade structure of the underpassing operation bridge 6 of the present invention. In the design process, the slope ratio m of the light subgrade is taken as 0.2, and the thickness of the soil filler 4 is h n2 Take 0.5m, the cantilever thickness b at both ends of the U-shaped light trough 3 (the thickness of the bottom plate is 1.5m) is 1.0m, and the top surface of the subgrade is laid with 8R9SI type slab ballastless track. Carry out design by design method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com