Dual-joint plate square steel pipe column-K-shaped steel supporting connecting joint

A technology of double gusset plates and connecting nodes, applied in the direction of building and building structure, can solve the problems of troublesome node design, affecting the low-cycle fatigue life of supports, troublesome production, construction and installation, etc., so as to avoid welding operations and improve construction. Efficiency, the effect of reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

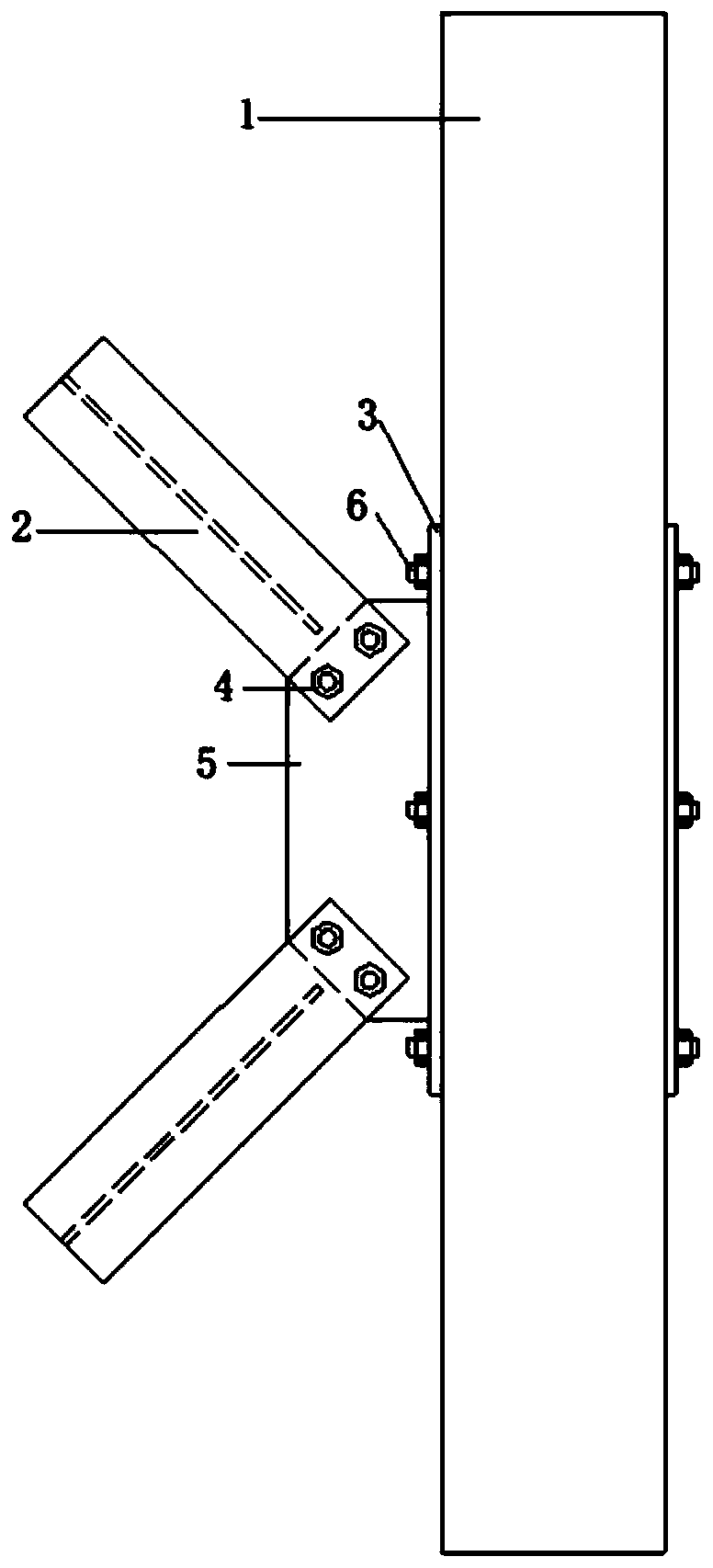

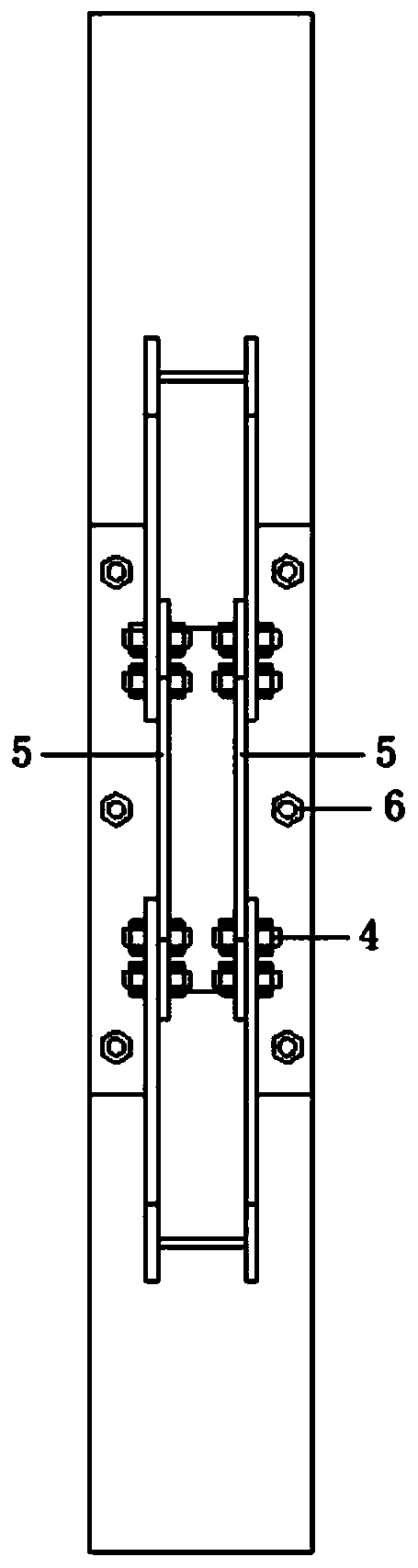

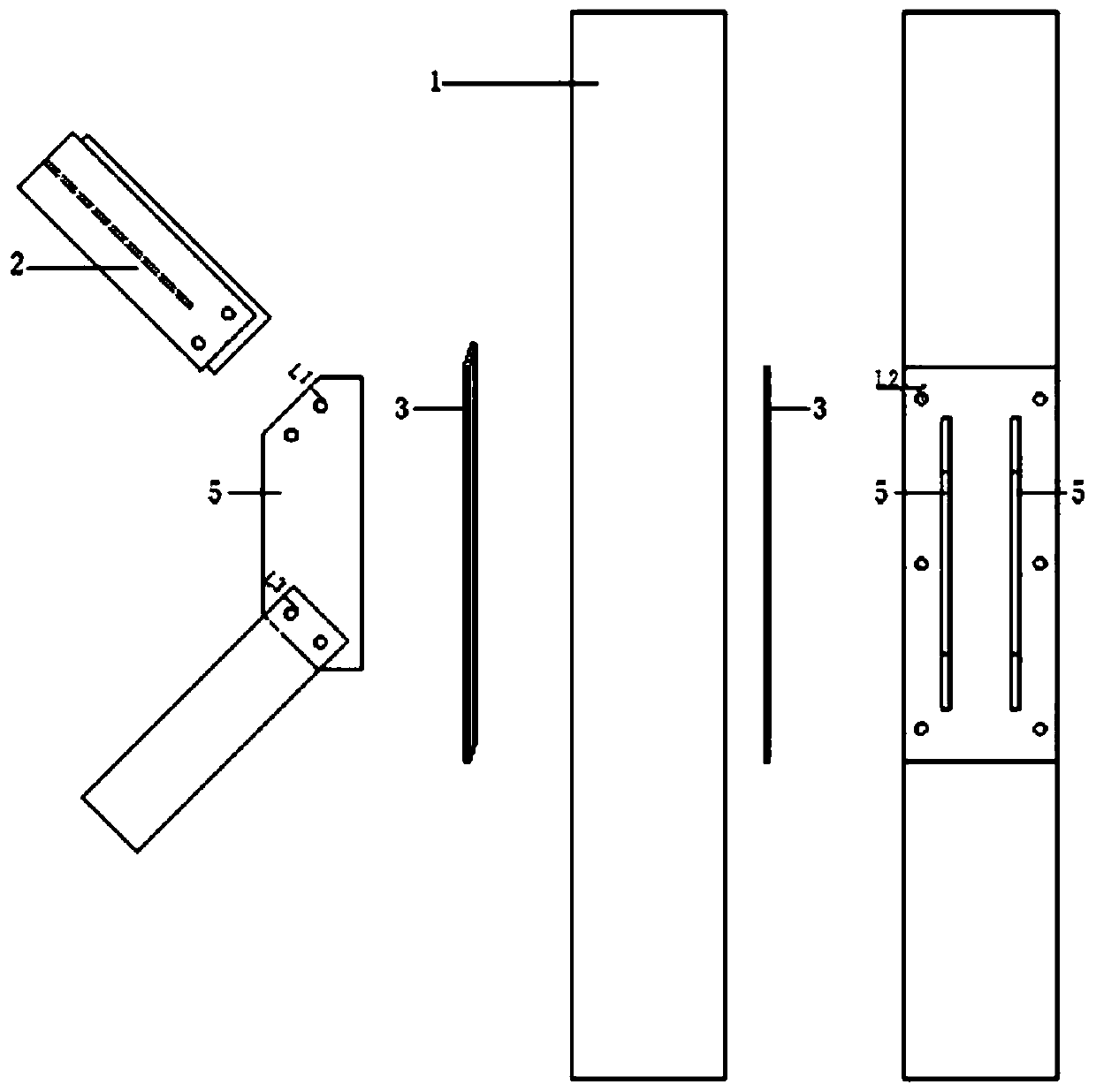

[0043] In the factory, two bolt holes are set on the upper and lower sides of the gusset plate 5. The diameter of the bolt hole is 22mm, and the distance L1 between the center of the bolt hole and the edge of the gusset plate (vertical to the direction of internal force) is 40mm, and the two gusset plates 5 are welded On the steel plate 3, six bolt holes of the same diameter are opened in the corresponding positions of the square steel pipe column 1 and the steel plate 3. Pull the bolt 6 (20mm in diameter) to fix the steel plate 3 on both sides of the square steel pipe column 1, cut off a piece of web at the end of the steel support 2, and open two screw holes on the upper and lower flanges, the screw hole diameter is 22mm , the distance L3 from the center of the screw hole to the edge of the flange (perpendicular to the direction of internal force) is 35mm.

[0044] At the construction site, push the two gusset plates 5 into the upper and lower flanges of the steel support 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com