Assembled steel pipe upright post system

A steel pipe column and assembled technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of inconvenient installation and dismantling, difficulty in on-site installation, inconvenient dismantling and construction, etc., to achieve fast and convenient installation and on-site work The effect of small quantity and convenient and quick dismantling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Assembling vertically

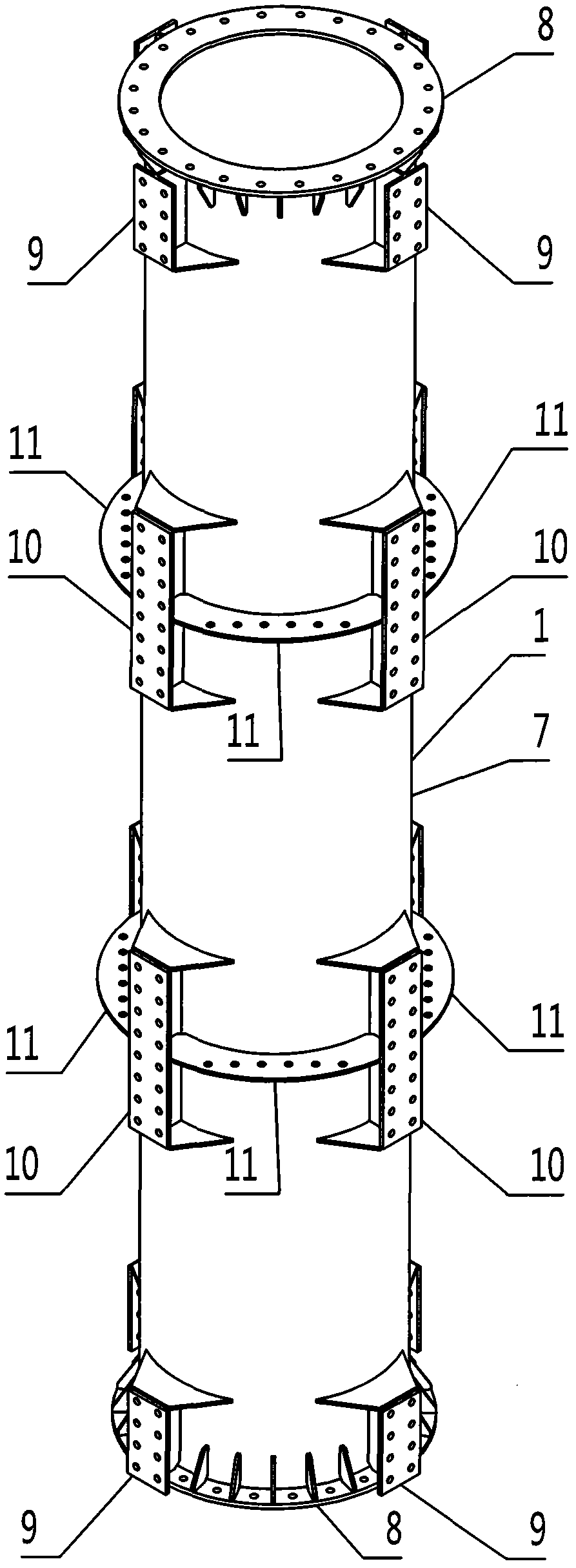

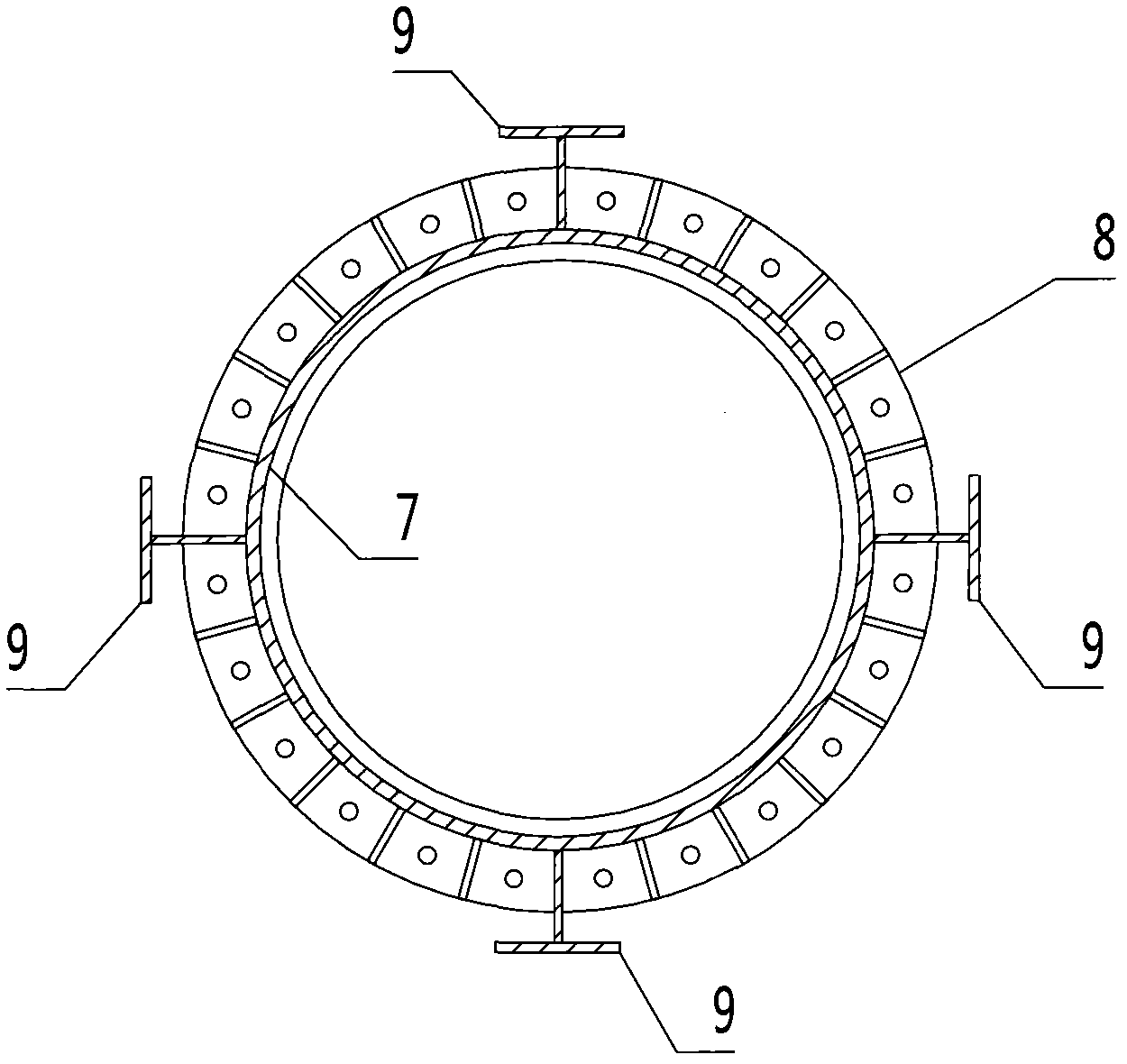

[0034] join Figure 4 and Figure 5 As shown, in order to make the present invention assemble and expand in the vertical direction, two or more column sections 1 can be connected as a whole by bolts at the end flanges 8 between them, and the bottommost The end flanges 8 can be connected with foundation anchors, and the topmost end flange 8 can be connected with the superstructure.

[0035] It can be known from Example 1 that the present invention can be assembled into any column structure whose height is multiples of the length of the standard column segment 1 .

Embodiment 2

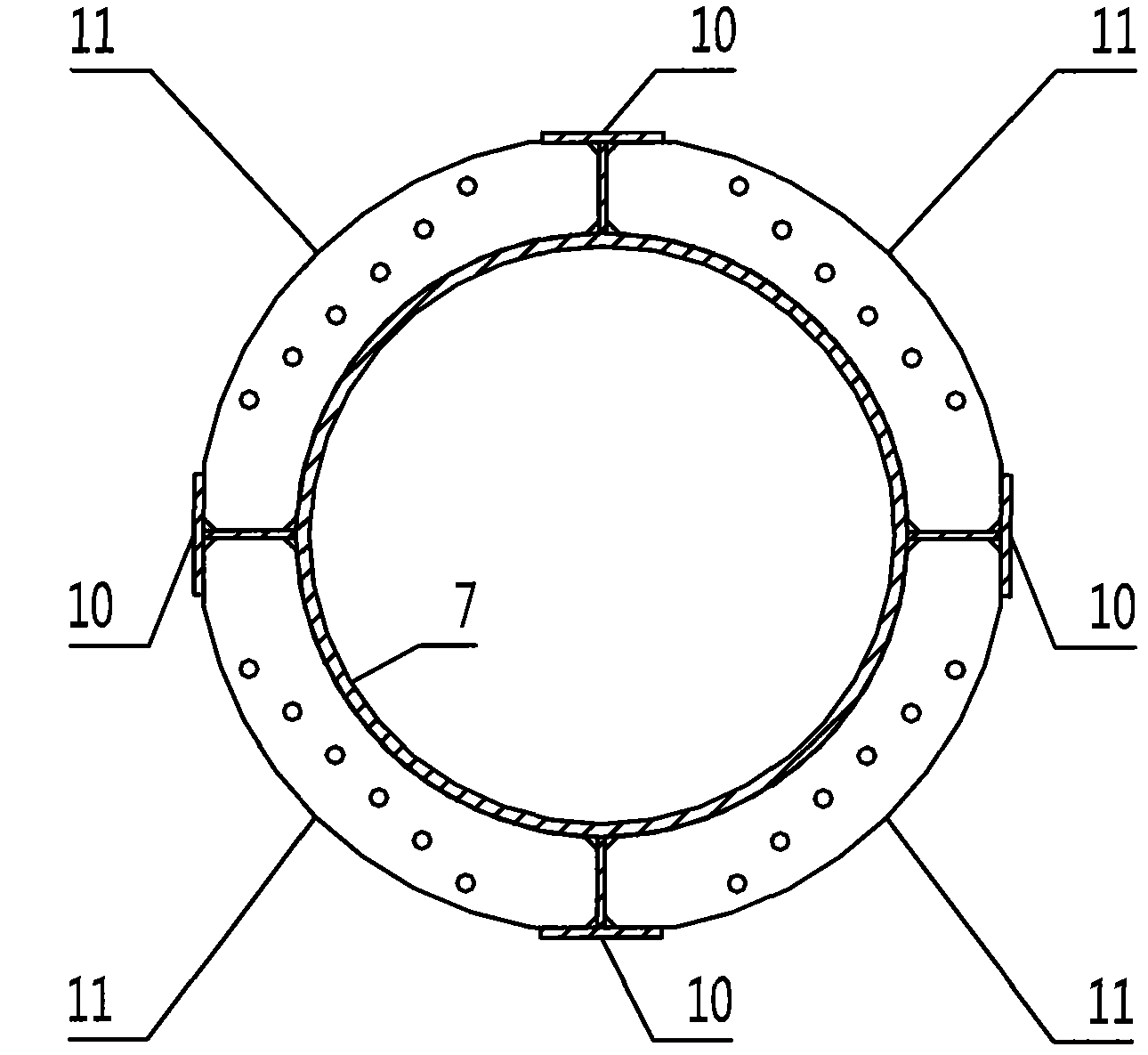

[0036] Example 2: Horizontal assembly, that is, side-by-side expansion

[0037] join Image 6 and Figure 7 As shown, in order to make the present invention assemble and expand in the horizontal direction, two rows or more than two rows of column segments 1 can be used, and the end T-shaped joints 9 and the middle T-shaped joints 10 are connected to each other by bolts. Together, they become close columns that can withstand doubled vertical loads.

[0038] It can be known from Example 2 that the present invention can be assembled into a side-by-side structure composed of any number of column segments 1 .

Embodiment 3

[0039] Example 3: Horizontal grouping and expansion, standard small column spacing arrangement

[0040] In order to make the present invention assemble and expand in the horizontal direction, two or more rows of column segments 1 can also be arranged with a certain column pitch, and the column segments 1 between rows pass through T-shaped gusset plates 2, Components such as the horizontal gusset plate 3 , the oblique connecting rod 4 , the transverse connecting rod 5 and the horizontal diagonal connecting rod 6 are bolted into one body. The oblique connecting rods 4, transverse connecting rods 5, and horizontal diagonal connecting rods 6 are shaped steel or steel pipes with different lengths, and bolt holes are provided at both ends for connecting with the T-shaped gusset plate 2 or the horizontal gusset plate 3.

[0041] see Figure 8 As shown, the T-shaped gusset plate 2 is welded by two steel plates arranged in a "T" shape, and bolt holes are provided on the two steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com