High-strength bolt connection arc end plate slippage friction energy consumption column base joint

A high-strength bolt and friction energy-dissipating technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of plastic damage of column foot joints, loss of building function, and repair of permanent structural deformation, so as to avoid welding operations and engineering Efficient construction, avoiding plastic deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] As one of the implementation methods, the upper and lower arc end plates are convex arc plates, the bolt holes of the upper arc end plate are oblong bolt holes, the bolt holes of the lower arc end plate are standard round holes, the lower steel columns are of equal cross-section, and the thickness of the upper and lower steel columns is same.

[0029] As one of the implementation methods, the upper and lower arc end plates are concave arc plates, the bolt holes of the upper arc end plate are oblong bolt holes, the bolt holes of the lower arc end plate are standard round holes, the lower steel columns are of equal cross-section, and the thickness of the upper and lower steel columns is same.

[0030] As one of the implementation methods, the upper and lower arc end plates are convex arc plates, the bolt holes of the upper arc end plate are oblong bolt holes, the bolt holes of the lower arc end plate are standard round holes, the lower steel columns are of variable cross-...

Embodiment 1

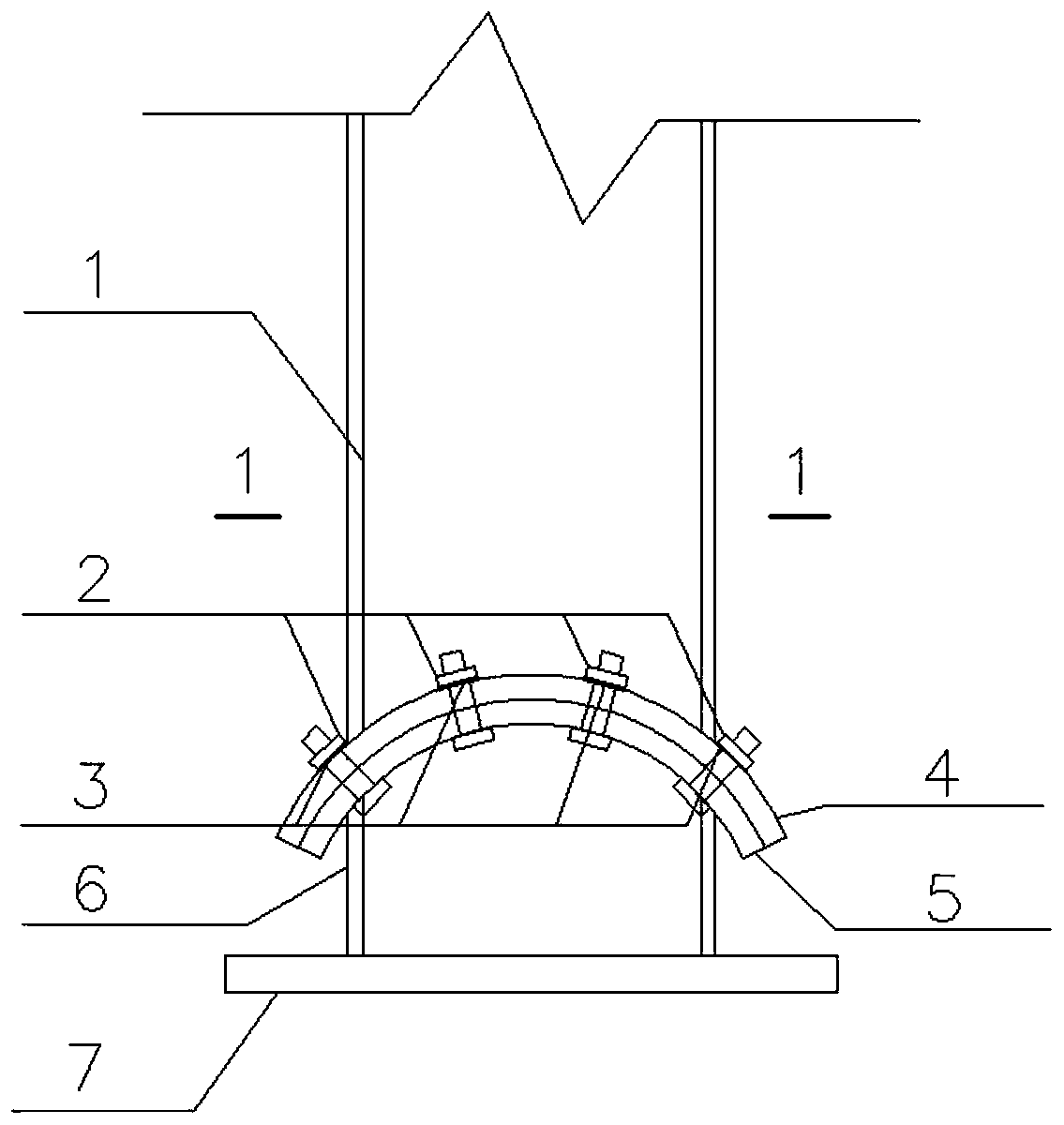

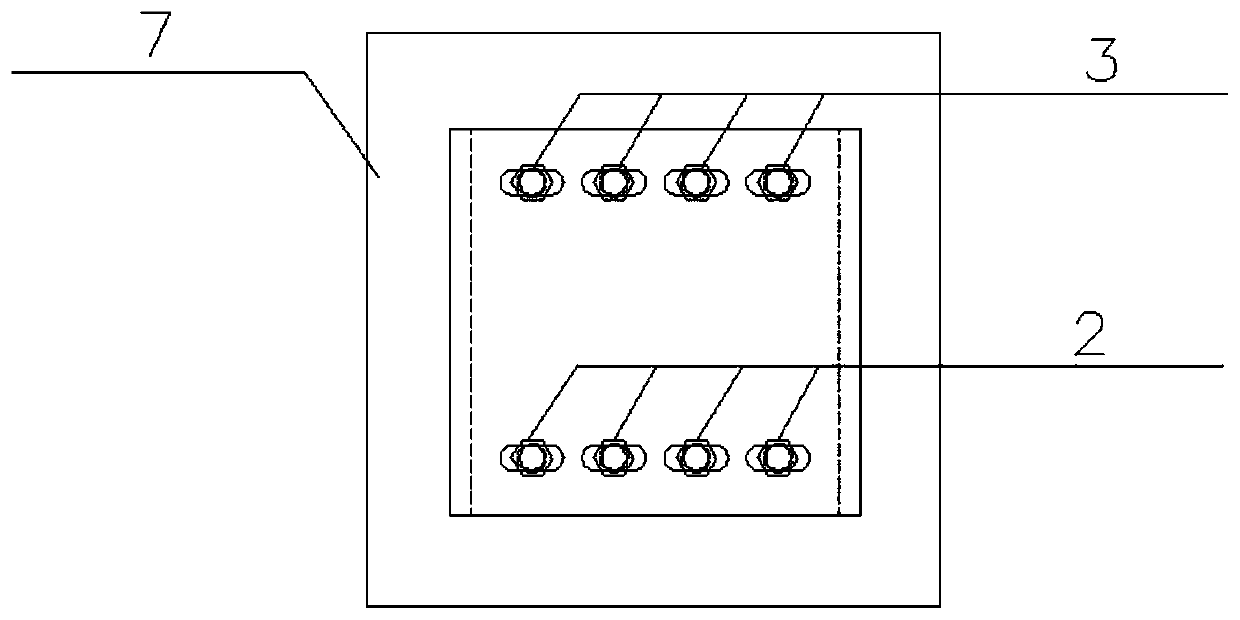

[0035] see figure 1 , image 3 , The arc-shaped end plate connection node is composed of an upper steel column 1, a high-strength bolt 2, a disc spring 3, an upper arc end plate 4, a lower arc end plate 5, a lower steel column 6, and a bottom plate 7. Wherein, the upper arc end plate 4 adopts oblong bolt holes, and the lower arc end plate 5 adopts standard round holes. The upper steel column 1 and the upper arc end plate 3, the lower steel column 5 and the lower arc end plate 4 are all welded by weld seams, and the disc spring 3 is set on the screw rod of the high-strength bolt 2 and placed under the nut. Disc spring 3 , upper arc end plate 4 and lower arc end plate 5 are connected by high-strength bolts 2 . The bolt hole diameters and the bolt hole spacing between the disc spring 3 , the upper arc end plate 4 and the lower arc end plate 5 correspond one-to-one.

[0036] In the connection nodes mentioned above, the steel of the upper steel column 1 and the lower steel colum...

Embodiment 2

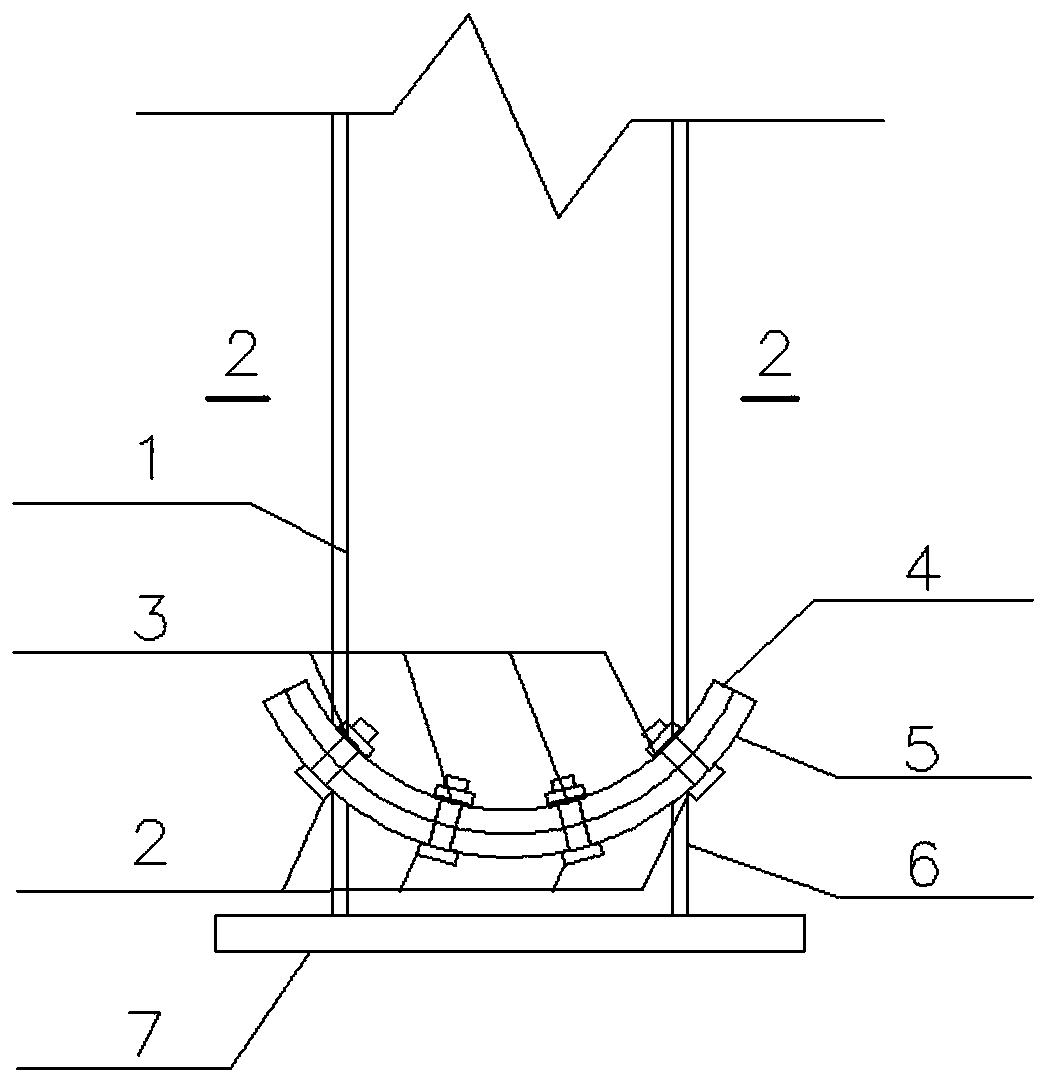

[0063] see figure 2 , Figure 4 , the design method and theoretical calculation method of this embodiment are the same as those of Example 1, and will not be repeated here. Different from Embodiment 1, the upper arc end plate 4 and the lower arc end plate 5 both adopt concave end plates.

[0064] Through the finite element simulation of ANSYS, it can be seen that Figure 9 The hysteresis curve shown is close to a parallelogram, which reflects the large slip deformation characteristics of the nodes. When the load is reversed after unloading, the stiffness of the joints still does not decrease, indicating that the overall stiffness degrades little. The shape of the hysteretic curve is full without pinching, indicating that the joint form has good deformation capacity and energy dissipation capacity, and the bearing capacity of the concave joint is slightly lower than that of the convex joint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com