Construction robot and construction method for reinforcing tunnel sticky steel

A technology of robots and tunnels, applied in tunnels, tunnel linings, instruments, etc., can solve the problems of manual or other equipment cooperation, difficulty in fixing steel plates, and low level of automation, and achieve the effects of saving manpower, high degree of automation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

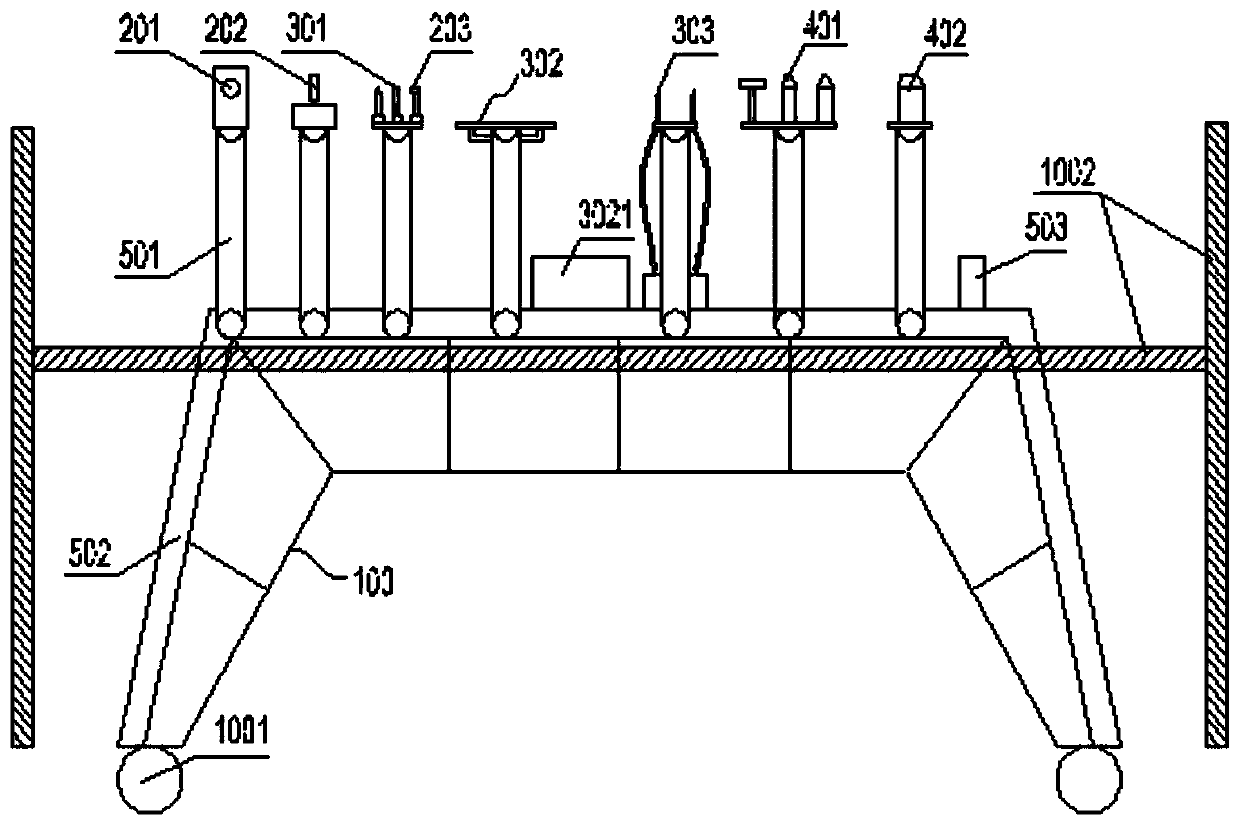

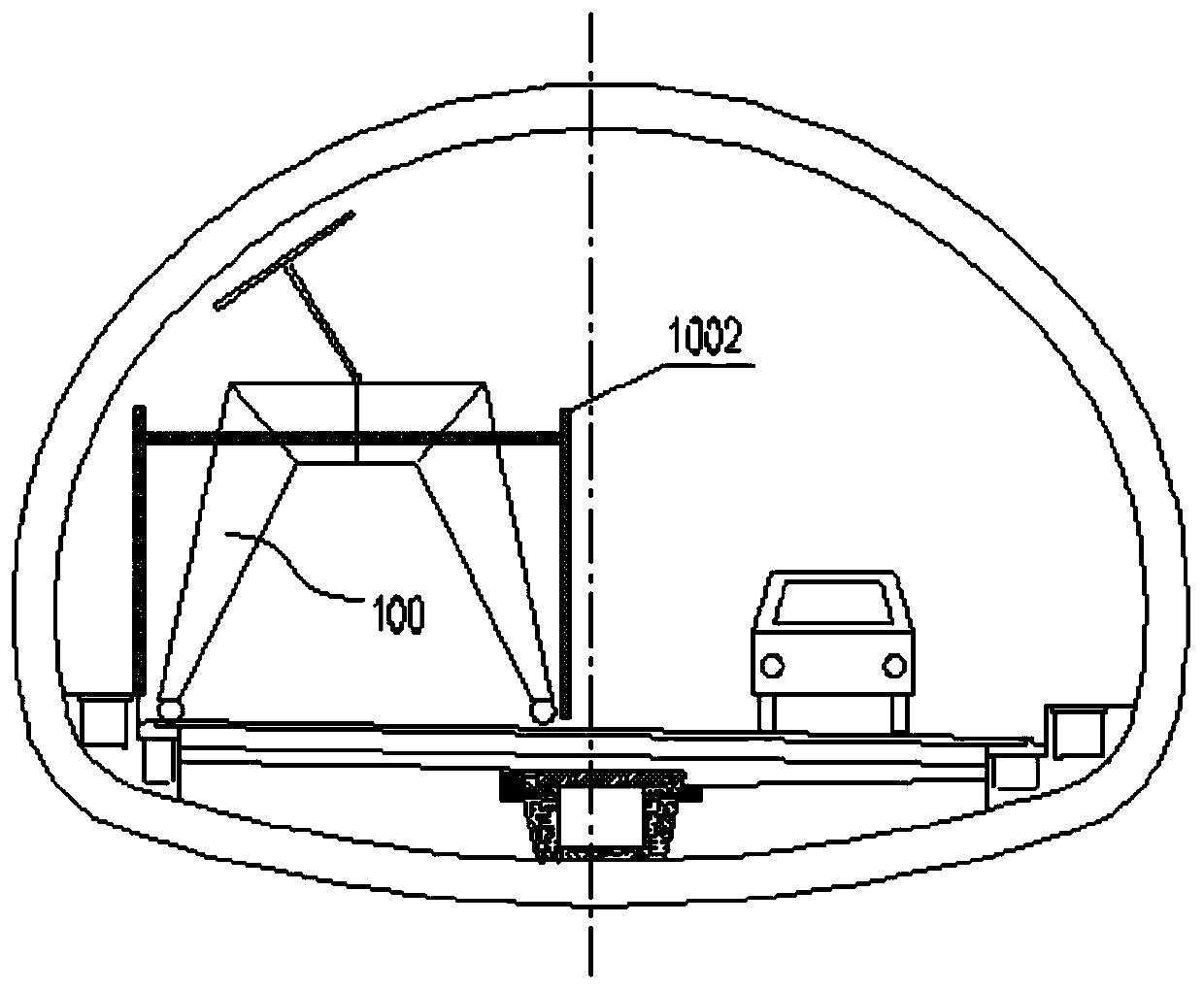

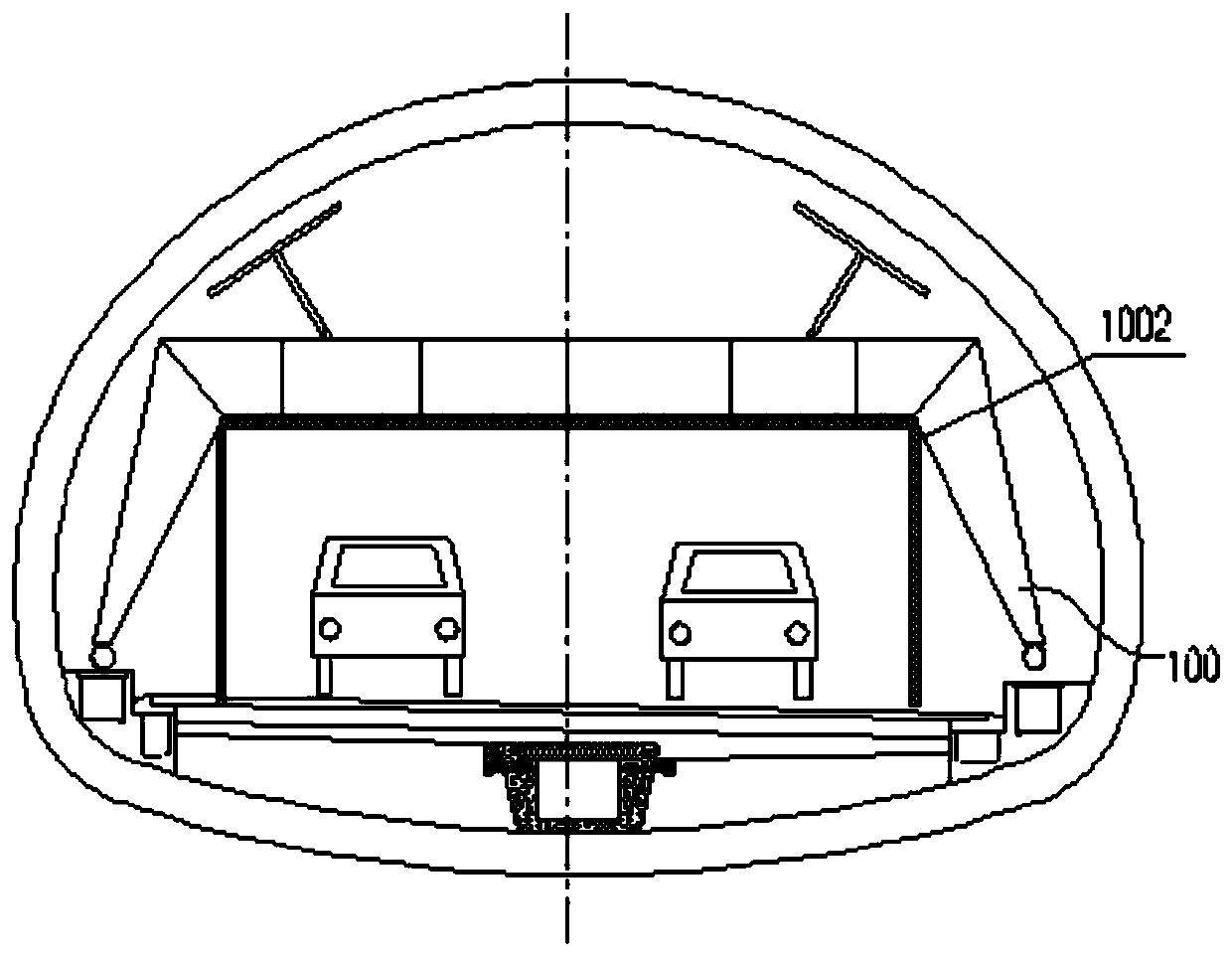

[0044] A construction robot for bonding and reinforcing tunnels with steel, which is used to reinforce tunnels by pasting prefabricated steel plates 304, including a working platform 100, a detection module and a construction module. The working platform 100 is provided with a track 502 and an industrial computer 503, and the track 502 Distributed on the top and opposite sides of the working platform 100, the detection module and the construction module are slidably installed on the track 502 through the mechanical arm 501 and connected to the industrial computer 503. There are two spherical joints on the mechanical arm 501. The mechanical arm 501 can Rotating around the spherical joint and the axis of the robot arm, the robot arm 501 changes the lateral position, vertical height and orientation of the detection module and the construction module by moving and rotating on the track 502, moves the detection module and the construction module to any position in the tunnel, and mak...

Embodiment 2

[0055] A construction method corresponding to Embodiment 1 using a construction robot for bonding steel reinforcement in tunnels, specifically:

[0056] The detection components are used for detection, including: the laser scanner 201 detects the prefabricated steel plate 304, obtains the actual profile and thickness of the prefabricated steel plate 304, and checks whether the bolt holes on the prefabricated steel plate 304 are blocked; the laser scanner 201 obtains the cross-sectional profile of the tunnel lining , the ultrasonic detector 202 acquires the positions and ranges of steel bars, cracks, shallow peeling and defects inside the tunnel lining, and the industrial computer adjusts the preset movement path of the mechanical arm 501 based on the detection results of the detection components;

[0057] Based on the detection and analysis of the detection components of the tunnel lining and the flatness of the prefabricated steel plate 304, the lining surface pretreatment is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com