Acoustic emission source positioning method and system based on linear weighted least square method

A least square method and acoustic emission source technology, which is applied in radio wave measurement systems, material analysis and positioning using acoustic wave emission technology, can solve problems such as real-time changes, heavy weights, and greater impact on positioning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

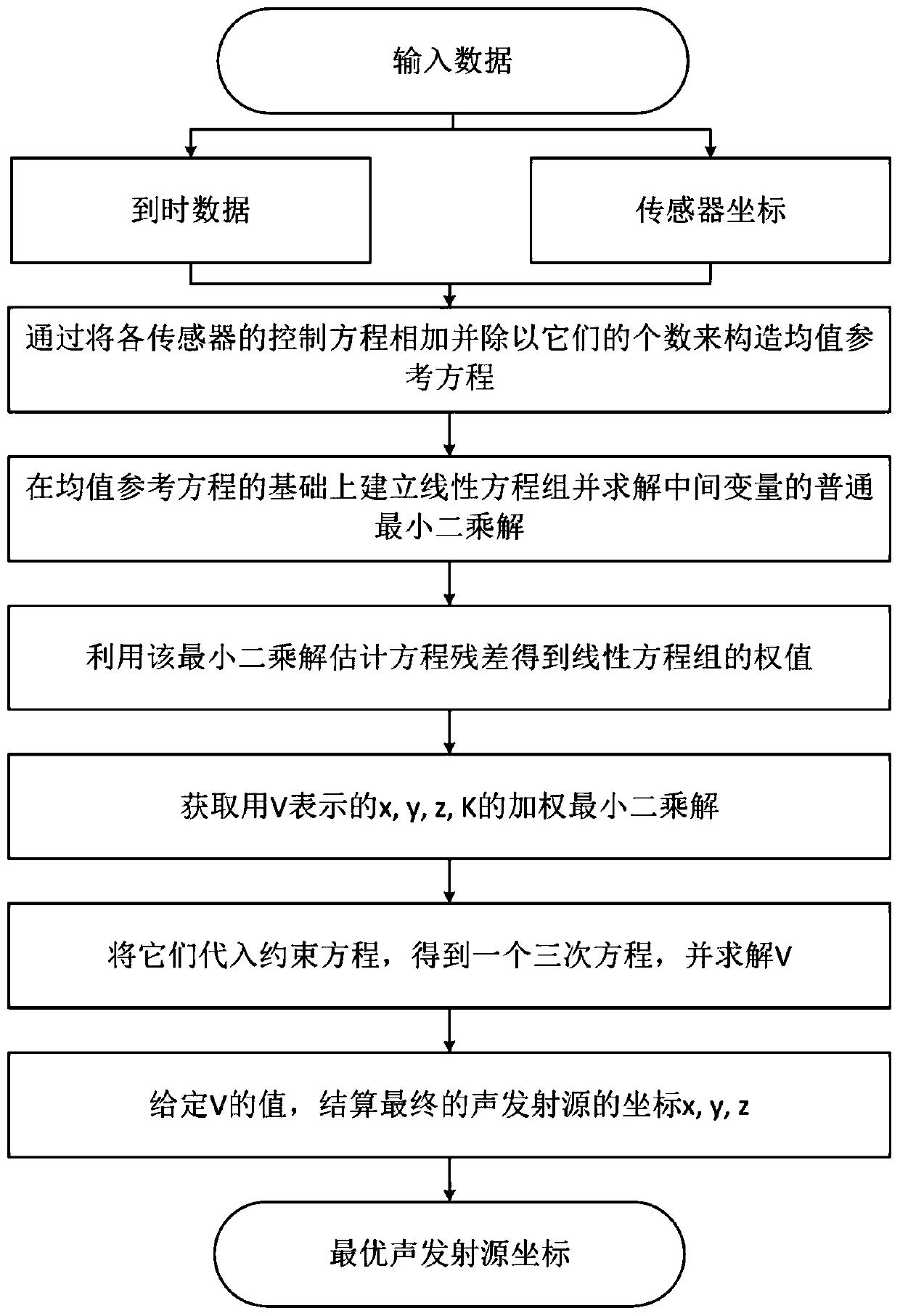

[0103] This embodiment provides a method for locating an acoustic emission source based on a linearly weighted least squares method, including the following steps:

[0104] Step 1, adding the distance time equations between each sensor and the acoustic emission source and dividing by the number of sensors to obtain the mean value reference equation (average reference equation);

[0105] Step 2. Based on the mean value reference equation, the nonlinear control equations composed of the distance time equations between each sensor and the acoustic emission source are converted into linear equations;

[0106] Step 3. Substitute the coordinates of each sensor and the time data when they receive the acoustic emission signal into the linear equations, and calculate the ordinary least squares solution V of the intermediate variables V and K (1) and K (1) , and then use them as prior solutions to estimate the covariance matrix Ψ of the linear equation; where the intermediate variable ...

Embodiment 2

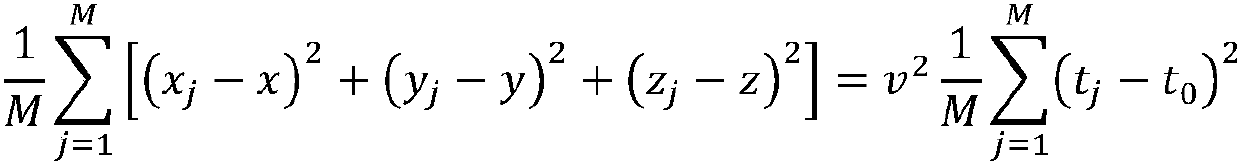

[0111]In this embodiment, on the basis of embodiment 1, in said step 1, the expression of the mean value reference equation is as follows:

[0112]

[0113] Among them, x, y and z respectively represent the three components of the coordinate θ of the acoustic emission source; x j ,y j and z j Represent the three components of sensor j coordinates; t j Indicates the time when sensor j receives the acoustic emission signal, and M indicates the number of sensors.

Embodiment 3

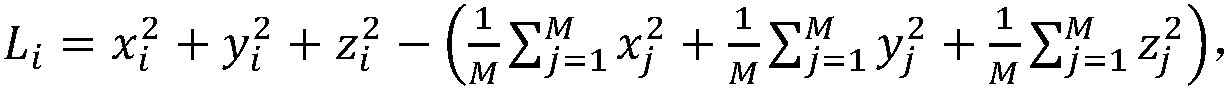

[0115] Present embodiment is on the basis of embodiment 2, and in described step 2, linear equations expression is as follows:

[0116] L i =a i x+b i y+c i z+d i K+e i V

[0117] Among them, L i 、a i , b i 、c i 、d i and e i are intermediate variables, and their expressions are:

[0118]

[0119]

[0120]

[0121]

[0122]

[0123]

[0124] And i=1, 2, . . . , M.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com