Belts and Belt Drives

A technology of belt transmission and belts, which is applied in the direction of transmission devices, belts/chains/gears, V-shaped belts, etc., can solve the problem of reducing the supporting surface of the belt and achieve the effect of low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

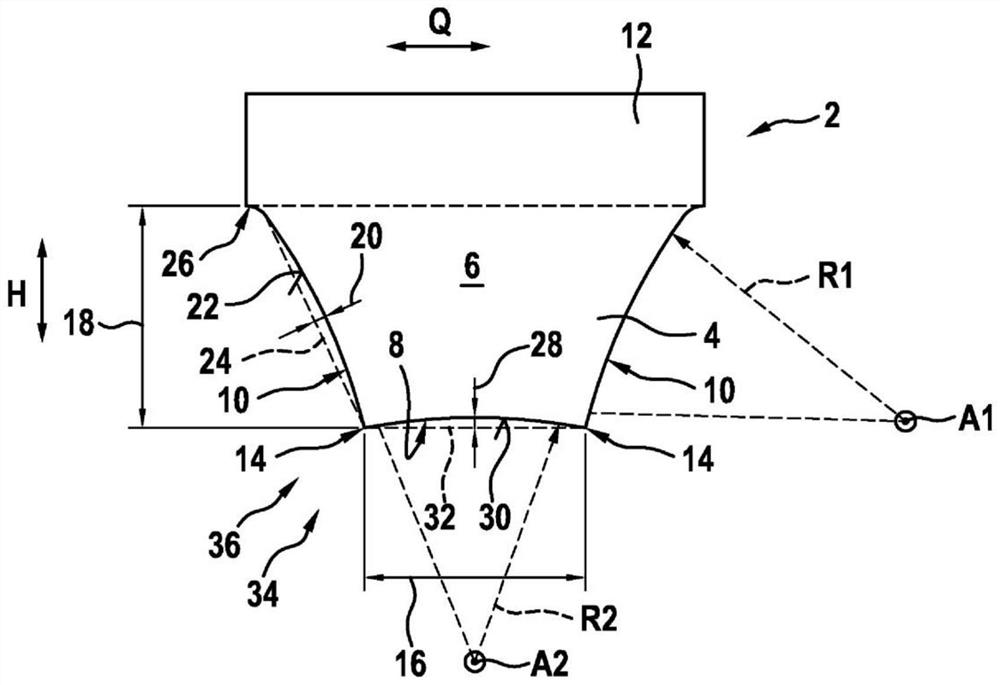

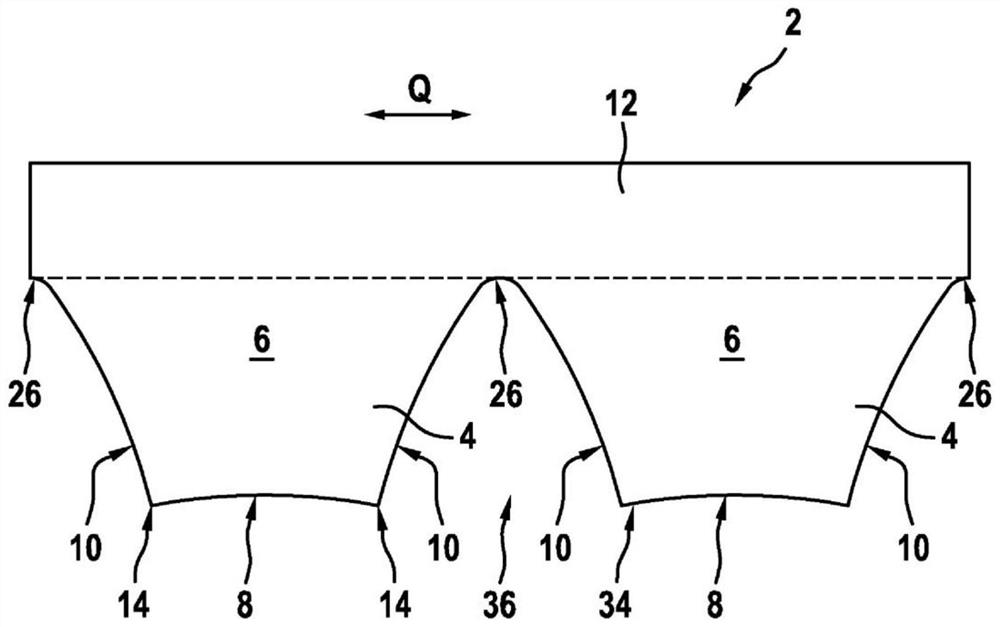

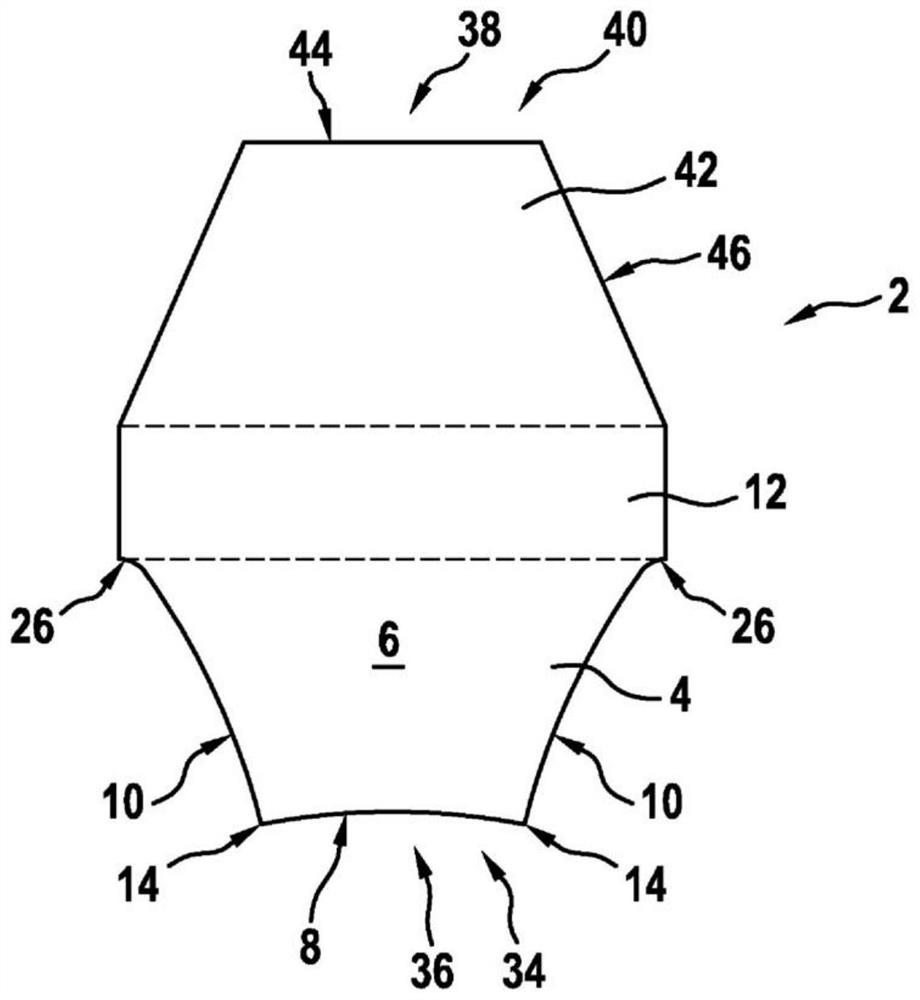

[0032] exist figure 1 The belt 2 is shown in a schematic cross-sectional view. The belt 2 has at least one rib 4 , also referred to as first rib 4 . The first rib 4 extends in the belt longitudinal direction. This is for example from Figure 4 available. Each first rib 4 has an at least substantially trapezoidal cross-section 6 . Due to the trapezoidal cross-sectional shape, each first rib 4 therefore has a support side 8 and two side faces 10 extending from the support side 8 . The supporting side 8 of the first rib 4 likewise extends in the longitudinal direction L of the belt. Each side face 10 of the first rib 4 also extends in the longitudinal direction L of the belt. Preferably, the trapezoidal cross-section 6 of each first rib 4 is formed symmetrically with respect to the side face 10 . Thus, the side faces 10 of the individual first ribs 4 are arranged symmetrically to one another. Furthermore, it is preferably provided that the respective side surfaces 10 of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com