Sludge treatment device

A sludge treatment and sludge technology, applied in the field of sludge treatment devices, can solve the problems of increasing the output power of hydraulic equipment, decreasing the elastic strength, reducing the extrusion effect, etc., so as to improve the force balance, improve the extrusion power, Improve the effect of the closure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

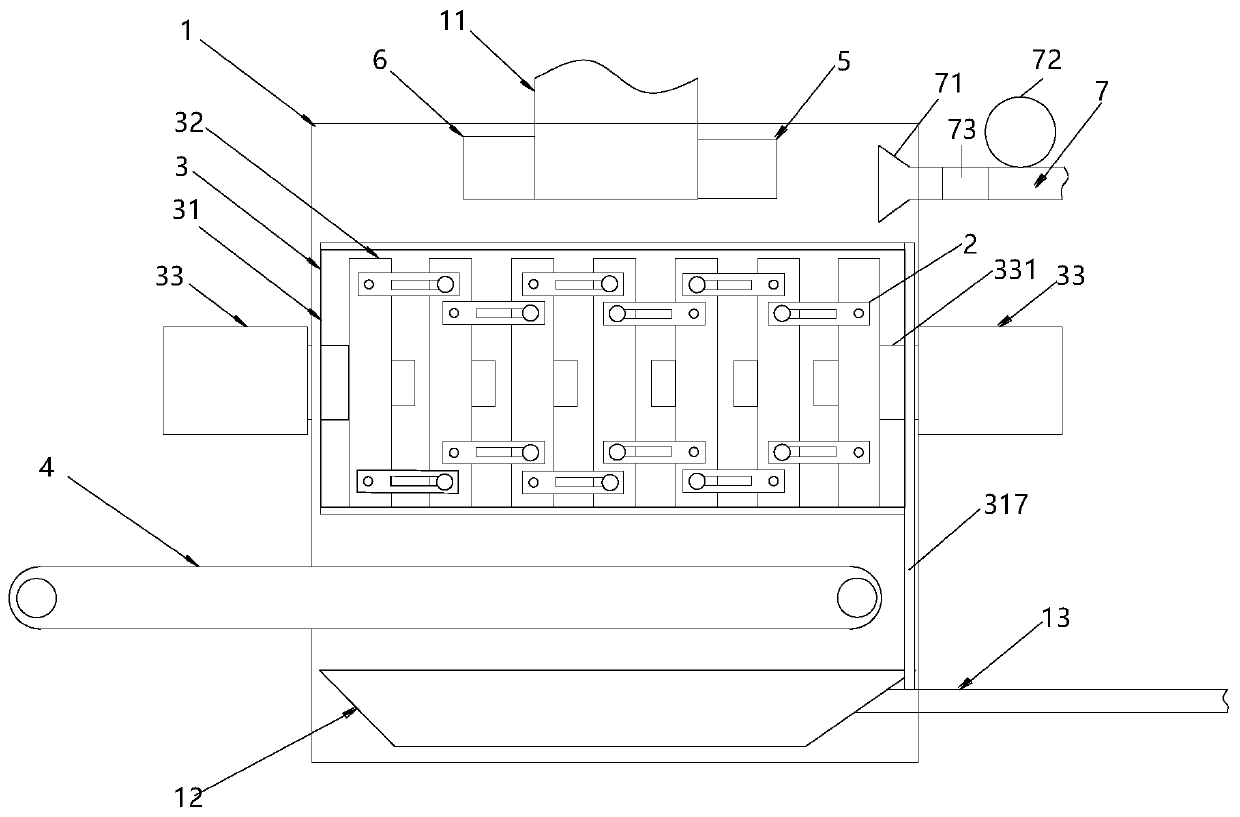

[0040] Such as figure 1 As shown, one embodiment of the present invention provides a sludge treatment device, including a hollow rectangular housing 1 as a workplace, and a sludge input pipeline 11 for external sludge input is arranged in the housing 1, and the imported sludge A filter press device 3 for press-filtering the mud, a conveyor belt 4 for outputting the sludge after the filter press, and a collection box 12 for receiving scattered sludge and fluid.

[0041] One end of the sludge input pipe 11 is used to connect the sludge supply point, and the other end extends into the housing 1, and the amount of sludge input can be controlled by the power equipment.

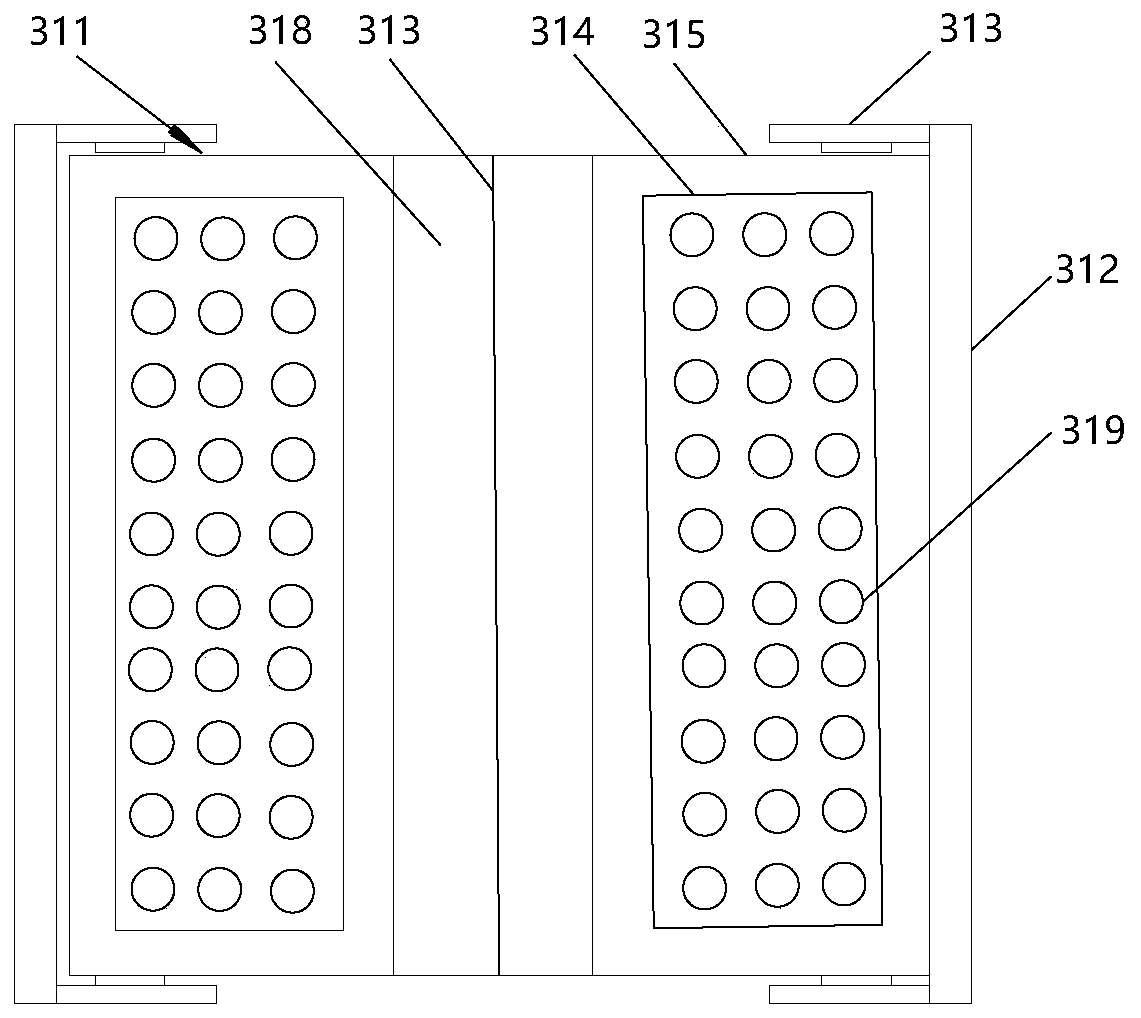

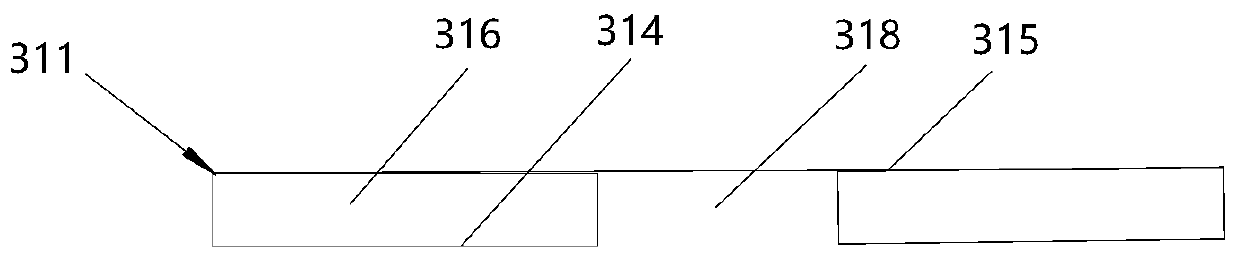

[0042]The filter press device 3 is located below the sludge input pipeline 11, and is used to receive the sludge input by the sludge input pipeline 11 and compress and filter it. It generally includes a squeeze chamber 31 for accommodating sludge, and is located in the squeeze chamber 31 to squeeze the sludge. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com