Harmless treatment method for stainless steel rolling oil sludge

A treatment method and technology of rolling oil sludge, applied in the direction of lubricating compositions, etc., can solve the problems of low oil cleanliness, environmental pollution, etc., and achieve the effect of high oil cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

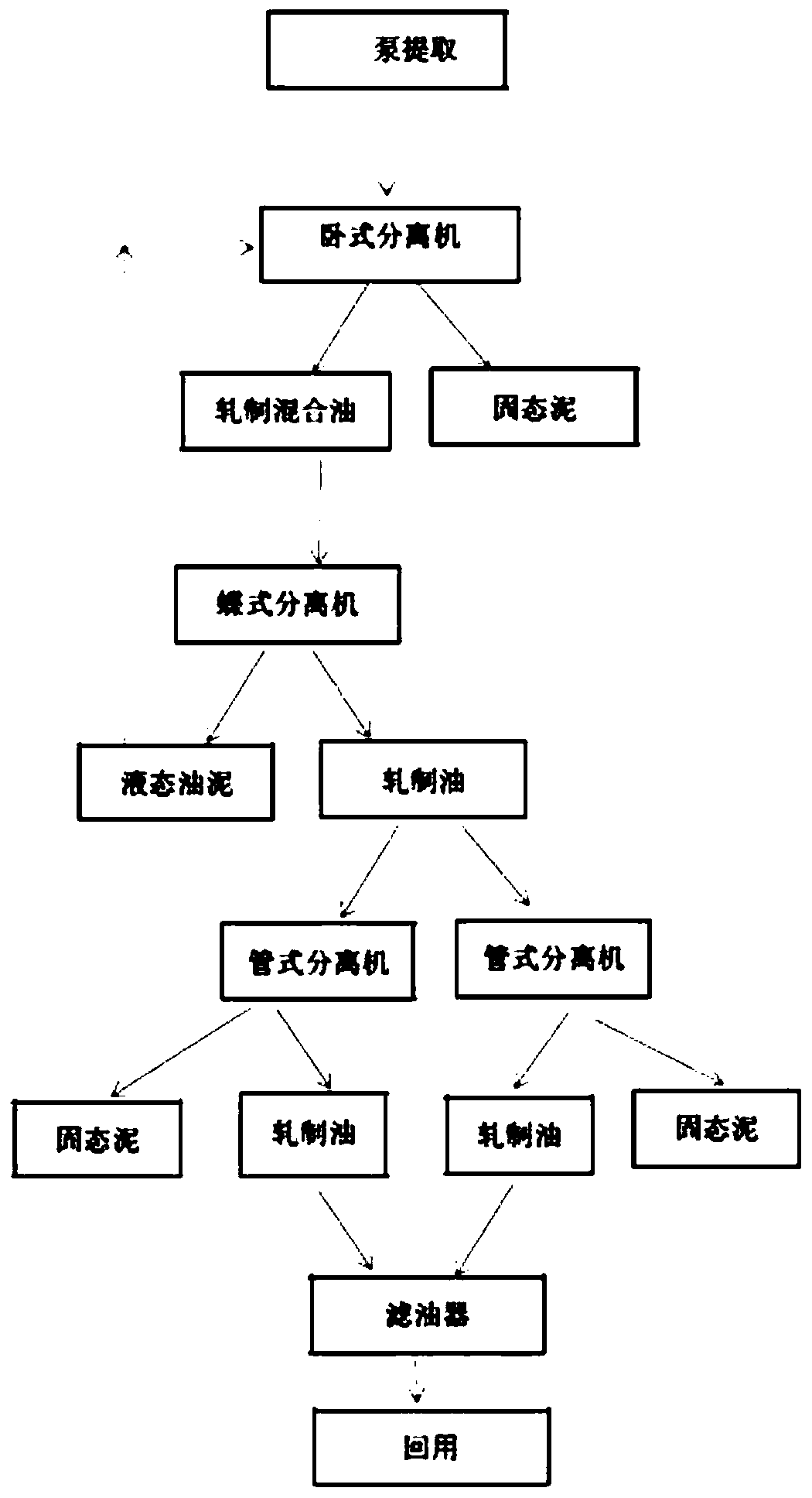

[0021] Such as figure 1 As shown, the harmless treatment method of the stainless steel rolling sludge of the present embodiment comprises the following steps in turn:

[0022] 1) Filter and stir the stainless steel rolling sludge in the sludge collector, and form a flowing liquid after stirring evenly;

[0023] 2) Primary separation: when the flowing liquid is conveyed by the mud pump at a flow rate of 500-1000 liters per hour, the solid particles in the flowing liquid can be crushed to a particle size of 1mm, and the crushed flowing liquid is transported to the horizontal centrifuge through the funnel In the machine, the rotating speed of the horizontal centrifuge is 5000r / min to carry out the solid-liquid preliminary separation of the flowing liquid. After one separation, the flowing liquid reduces 80% of the particles. In this way, the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com