High-pressure atomization spraying device special for electroplating production

A spray device and high-pressure atomization technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of tap water waste, low work efficiency, waste of tap water, etc., achieve water saving, semi-automatic cleaning, and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

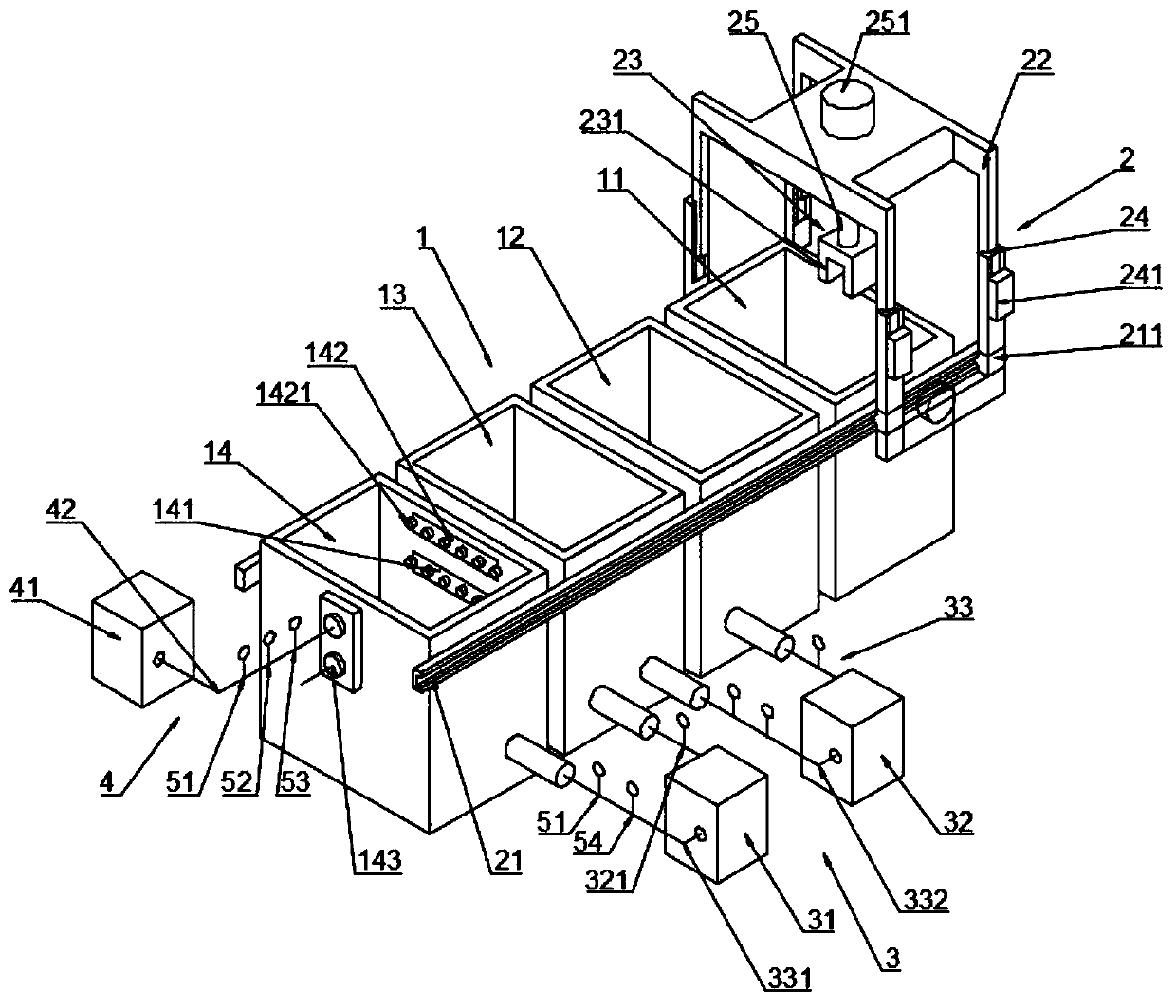

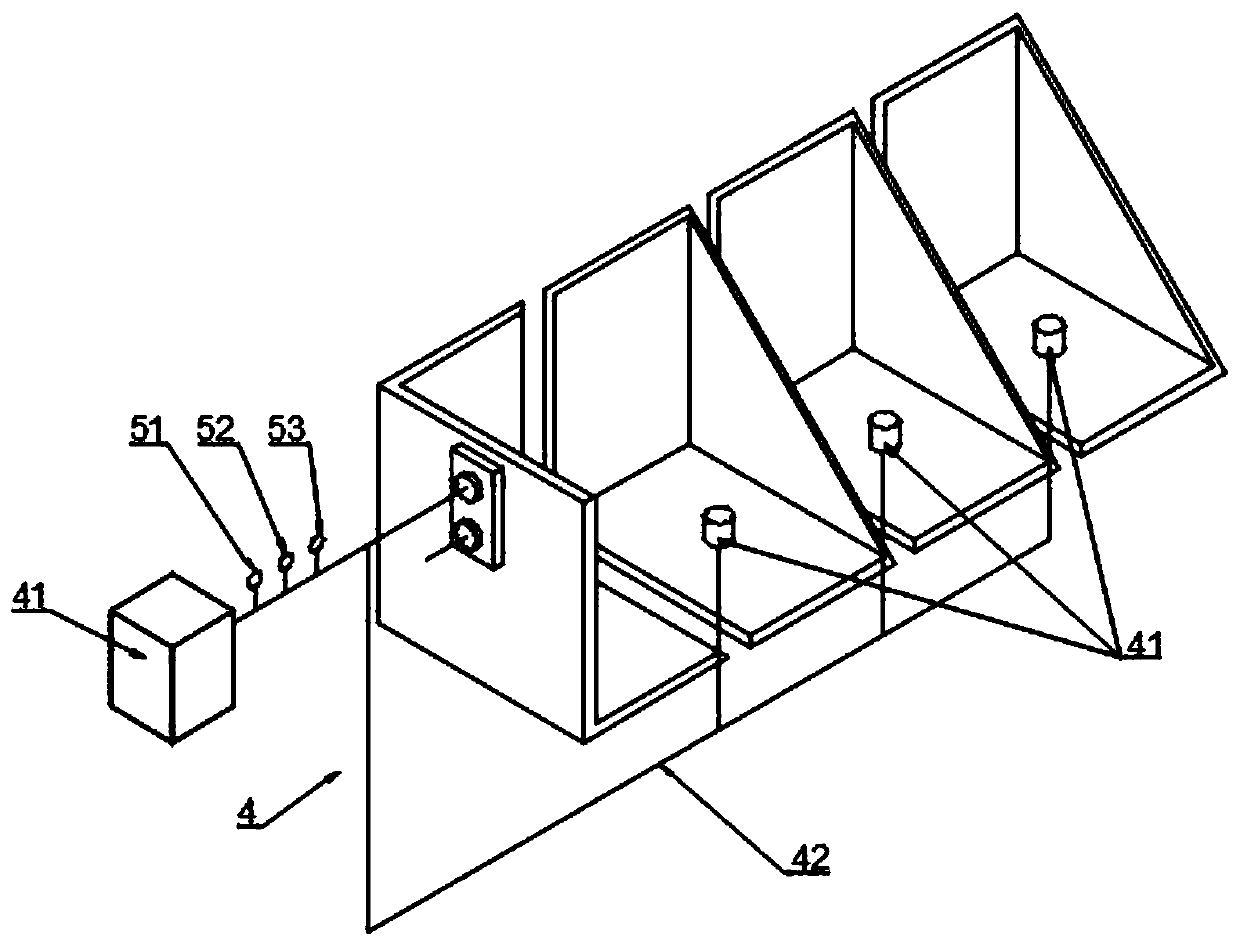

[0031] Such as figure 1 As shown, a special high-pressure atomizing spray device for electroplating production is composed of an electroplating cleaning device 1, a driving device 2 for moving electroplated parts on the electroplating cleaning device 1, a circulating water device 3 and an air supply device 4. .

[0032] The electroplating cleaning device 1 is composed of a washing tank 11, an electroplating tank 12, a soaking tank 13 and a cleaning tank 14 arranged in a line of "one", and the cleaning tank 14 is provided with a water inlet 143, between each tank Independent of each other; the bottom of the inner chamber of the washing tank 11, the soaking tank 13 and the cleaning tank 14 are all provided with an aeration head 43, and the aeration head 43 can stir the liquid in the tank, thereby driving the liquid to carry out the process on the surface of the plated piece. Flushing, so as to achieve better cleaning effect; described cleaning tank 14 inner cavity is provided w...

Embodiment 2

[0045] This embodiment except the following content, all the other parts are identical with embodiment one:

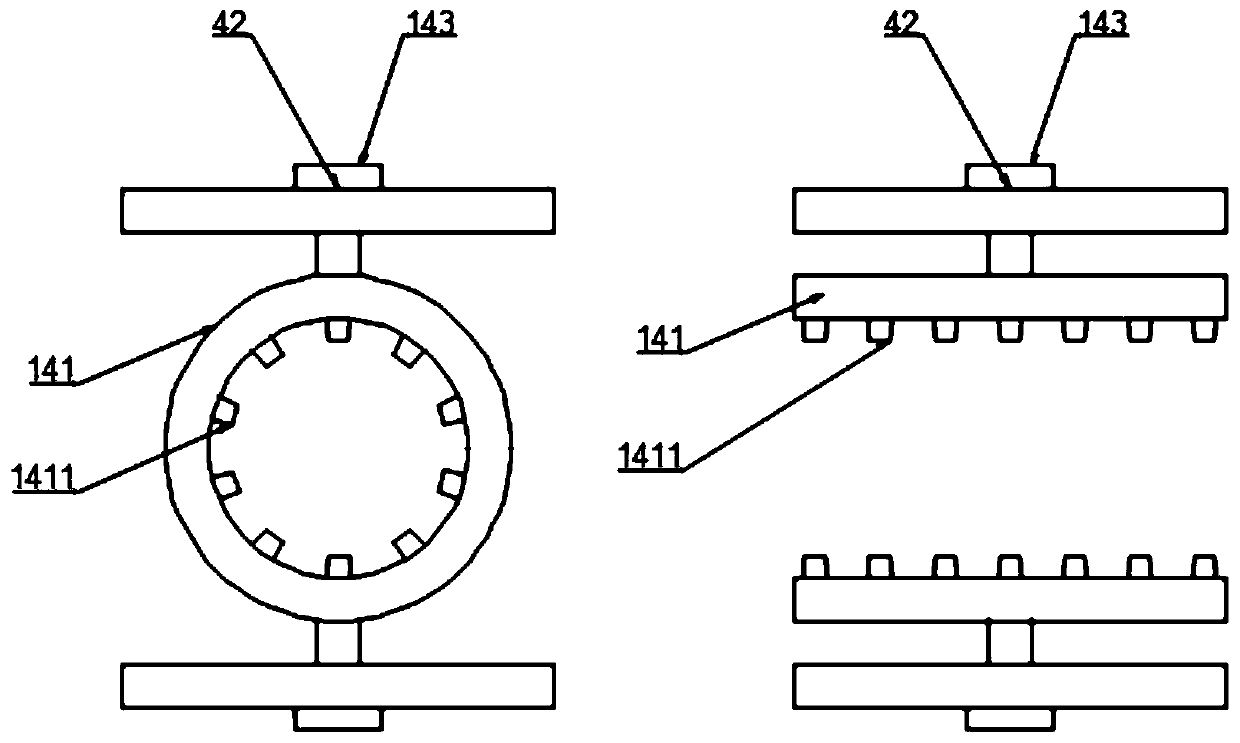

[0046] The inner cavity of the cleaning tank 14 is sequentially provided with draining racks 142 of ring-shaped cleaning racks 141 from bottom to top; The gas nozzle 1421; the nozzles of the annular cleaning frame 141 and the draining frame 142 are directed towards the center of the circle. The nozzles of the opposite type cleaning frame 141 and the draining frame 142 are arranged oppositely.

[0047] The distance between the draining racks 142 of the cleaning rack 141 can be regulated, and the spacing is adjusted according to the size of the plated parts. In this embodiment, the spacing is 25 cm.

Embodiment 3

[0049] This embodiment except the following content, all the other parts are identical with embodiment one:

[0050] The inner cavity of the cleaning tank 14 is sequentially provided with draining racks 142 of opposing cleaning racks 141 from bottom to top; on the opposing cleaning racks 141, 10 water mist nozzles 1411 are arranged on each side, and the relative setting Each side is provided with 10 gas nozzles 1421 on the drain rack 142.

[0051] The distance between the draining racks 142 of the cleaning rack 141 can be adjusted, and the spacing is adjusted according to the size of the plated parts. In this embodiment, the spacing is 10 cm.

[0052] Embodiment three

[0053] This embodiment except the following content, all the other parts are identical with embodiment one:

[0054] The inner cavity of the cleaning tank 14 is sequentially provided with draining racks 142 of opposing cleaning racks 141 from bottom to top; on the opposing cleaning racks 141, 13 water mist no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com