Integrated assembled frame structural building system

A frame structure, prefabricated technology, applied in construction, building construction, etc., can solve the problem of increasing construction costs and man-hours for installing metal sleeve connections and grouting, unable to detect grouting compactness and quality monitoring, and stress steel bar connection. Uncertain reliability and other problems, to achieve the effect of promoting industrial upgrading, reducing construction procedures, and improving the level of modernization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

[0047] The integrated assembled frame structure building system of the present invention includes a frame structure, wall panels and floor slabs, the frame structure includes frame columns and frame beams, and concrete is poured into the frame columns and frame beams;

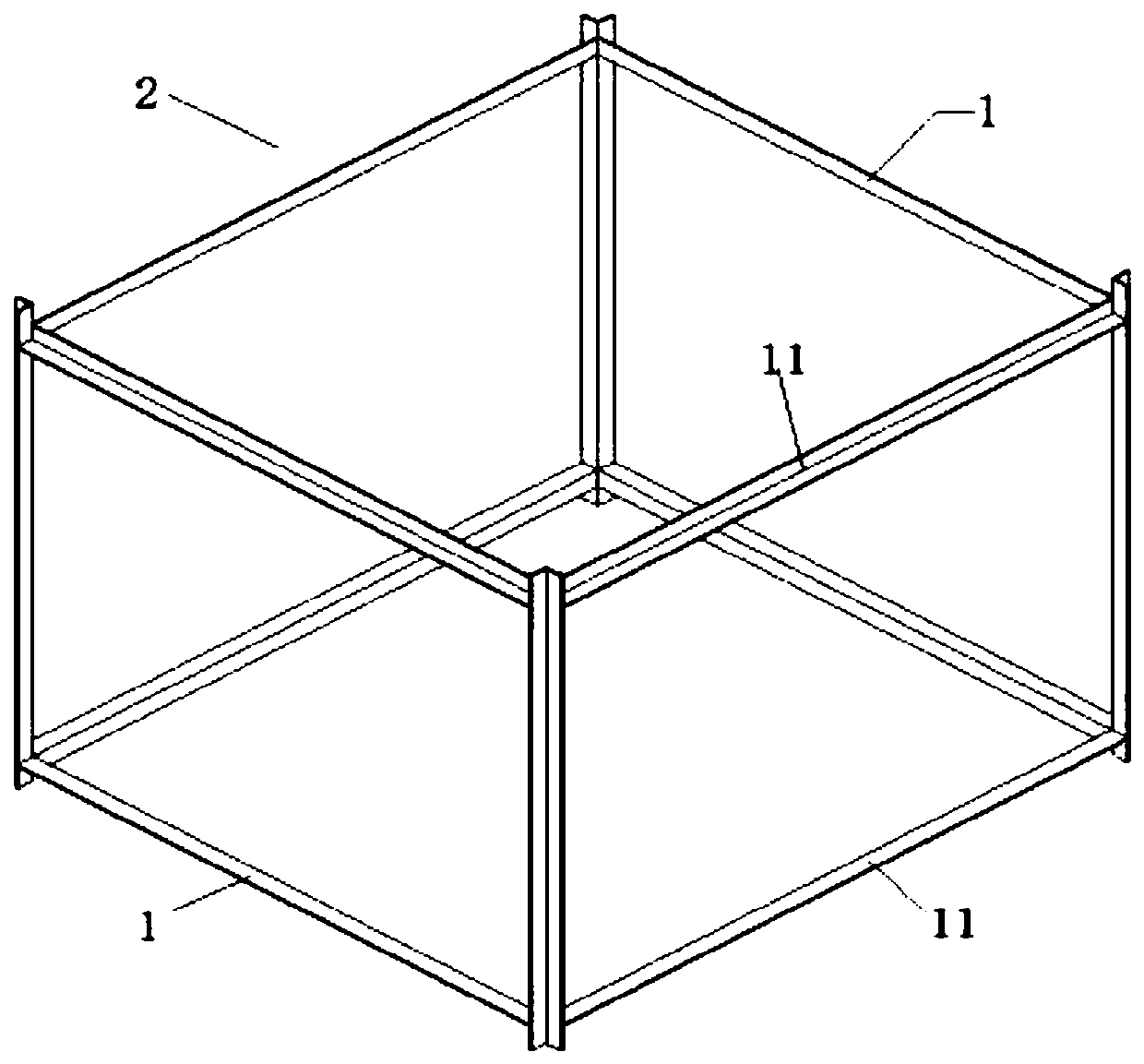

[0048] Frame columns and frame beams are composed of section steel skeletons, which include several unit planar skeletons 1 and unit three-dimensional skeletons 2;

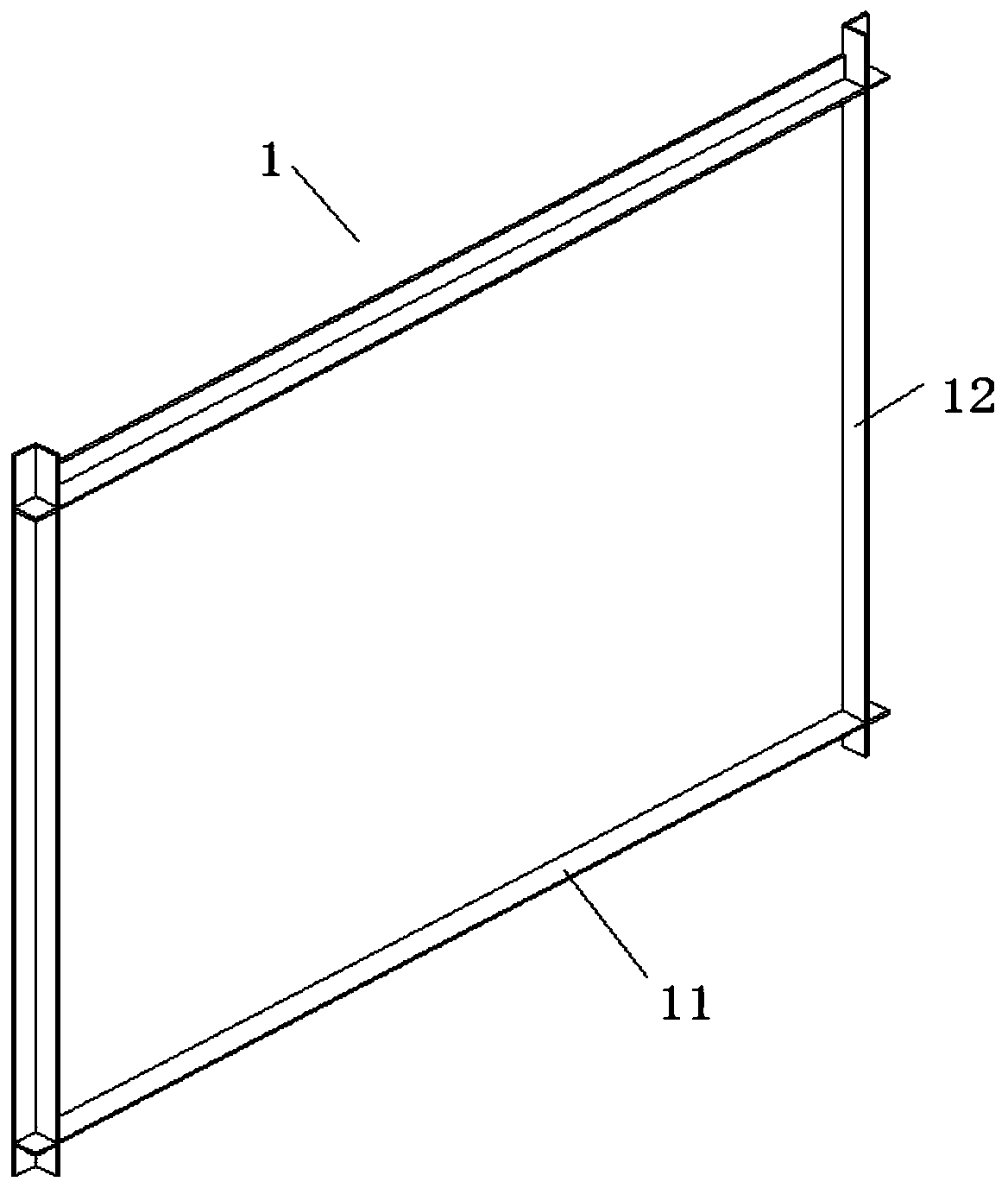

[0049] Such as figure 2 As shown, the unit plane skeleton 1 is a rectangle, including two parallel horizontal steel members 11 up and down and two parallel vertical steel members 12 on the left and right. The two ends of the member protrude from the horizontal steel member for a certain length; the horizontal steel member and the vertical steel member are "C", "U" or "L" steel, and the opening directions of the steel members are in the same di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com