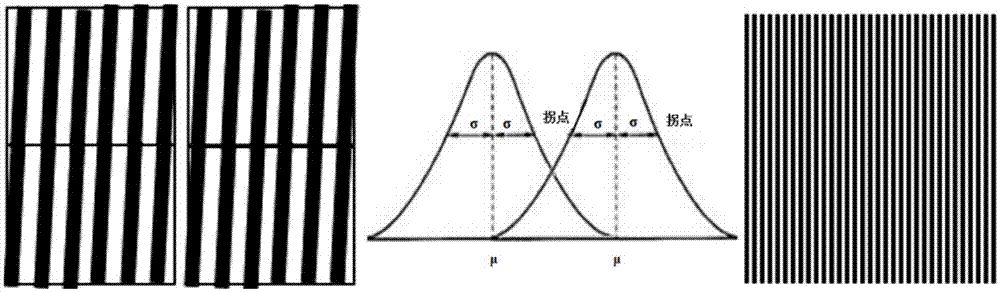

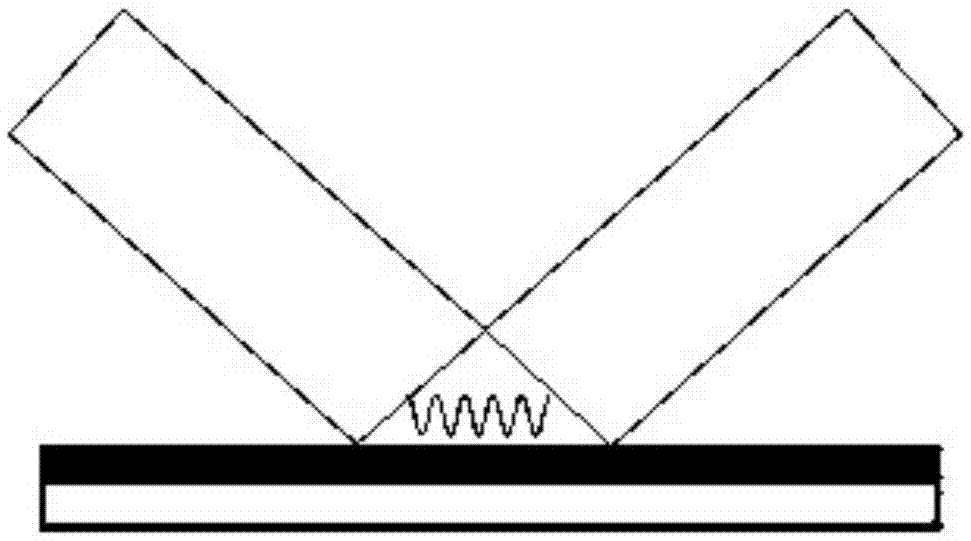

Manufacturing method for large-dimension diffraction grating and exposure device thereof

A diffraction grating and manufacturing method technology, applied in the field of large-scale diffraction grating production, can solve problems such as errors, interference spot edge diffraction, etc., and achieve the effects of improving splicing alignment, eliminating environmental interference, and enhancing system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

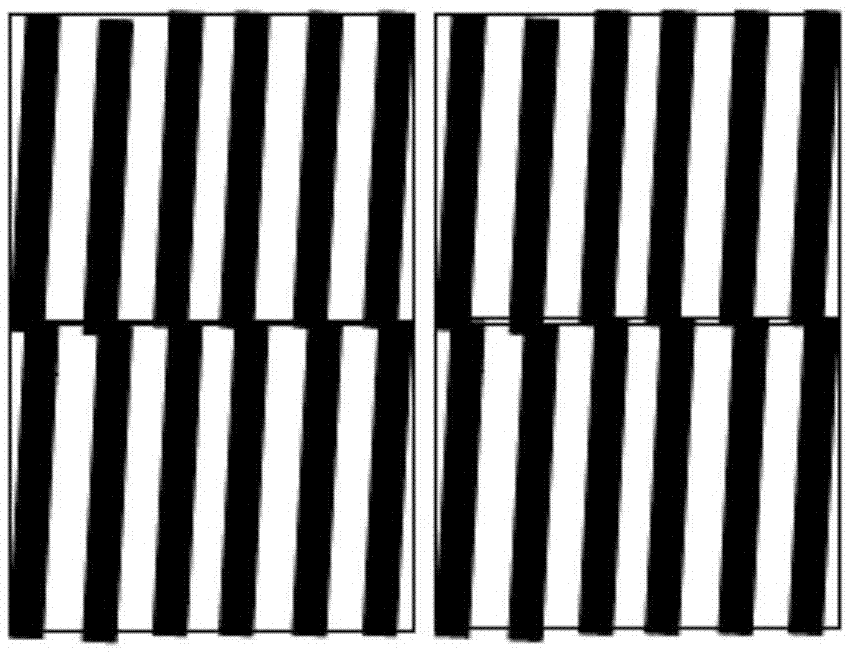

Embodiment 1

[0057] Example 1: Determine the spot size P = 200um, Λ = 500nm period, 2x2 overlapping tiling interference exposure, translation amount L = 100um, then accurately adjust the included angle Φ = 0.14 degrees, m =, then the interference fringes are aligned with r =L*sinΦ-mΛ=0. The exposure frequency is set to 2000 Hz, and the photolithography time of a 1mx0.4m diffraction grating is <6 hours.

[0058] Also set the spot size P=400um, 2x2 overlapped tiling interference exposure, the translation amount L=200um, precisely adjust the included angle Φ=0.072 degrees, the exposure frequency is 1KHz, and the photolithography time of 1mx0.4m diffraction grating is <3 hours .

Embodiment 2

[0059] Embodiment 2: Determine the angle between the scanning direction and the zero-order phase grating Φ=0.2 degrees, Λ=400nm period, 2x2 overlapped tiling interference exposure, then the scanning translation amount L=114.6um, and the spot size P=229.2 um, r=L*sinΦ-mΛ=0, to achieve interference fringe alignment.

Embodiment 3

[0060] Embodiment 3: Determine the angle between the scanning direction and the zero-order phase grating Φ=0.2 degrees, the spot size is 250um, the translation amount is 125um, M=20, then the zero-order phase grating translation amount is 1.45um, r=L*sinΦ -mΛ=0, to achieve interference fringe alignment.

[0061] In the above example, the movement of the zero-order phase grating will be slightly corrected according to the actual detection error, so that the efficiency of the entire splicing exposure is greatly improved.

[0062] When using a spot of more than 500um, the objective lens in the projection optics needs to be specially designed and processed to ensure that the numerical aperture NA is higher than 0.5. At the same time, the lens diameter is greater than 20mm and the focal length is less than 20mm to ensure the size of the exposure field of view.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com