Copper powder for infiltration

A technology of copper-based powder, which is applied in the field of copper-based powder, can solve problems such as substrate surface erosion, and achieve the effect of high infiltration rate and improved lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

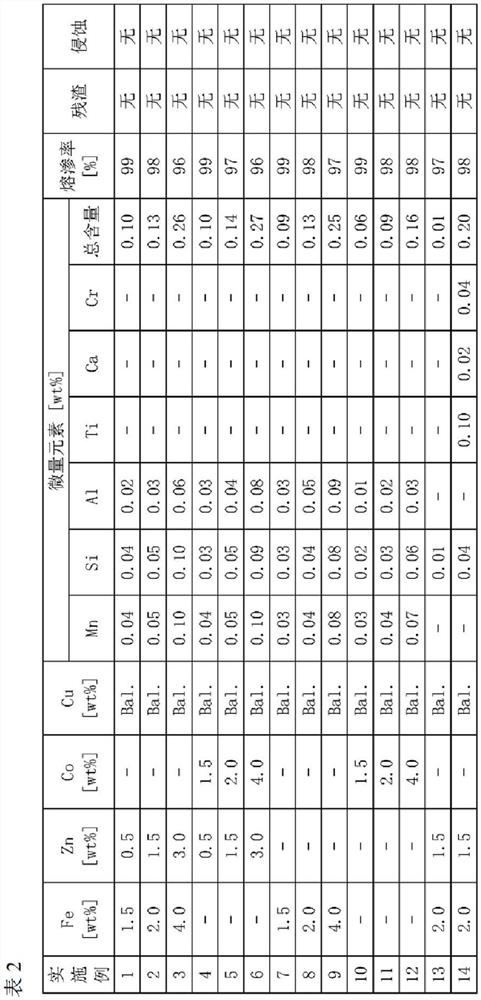

Embodiment 1

[0090] Using Cu-Fe-Zn alloy powder produced by the atomization method (Cu / Fe / Zn=Bal. / 1.5 / 0.5% by mass: adding an extremely small amount of Mn, Mn, Si, Al).

Embodiment 2

[0092] Cu-Fe-Zn alloy powder (Cu / Fe / Zn=Bal. / 4.0 / 3.0% by mass) produced by atomization method is added to molten soup in a very small amount of Mn, 50% by mass of Si and Al) and 50% by mass of Cu powder were mixed.

Embodiment 3

[0094] Only the same Cu-Fe-Zn alloy powder as in Example 2 was used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com