Preparation method of high-infiltration-rate infiltrated copper wire

A copper wire and high-melting technology, applied in the field of metallurgical copper infiltration, can solve the problems of restricting the development of high-end powder metallurgy preparation, poor mechanical properties and anti-wear performance, and difficult to clean residues, so as to avoid fracture, improve oxidation resistance, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

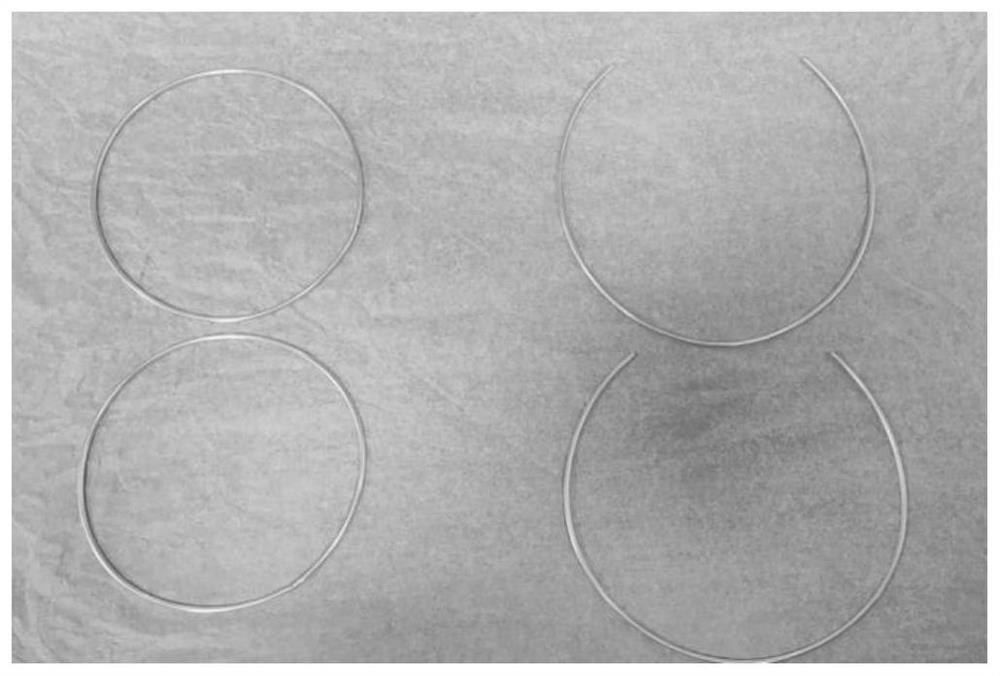

Image

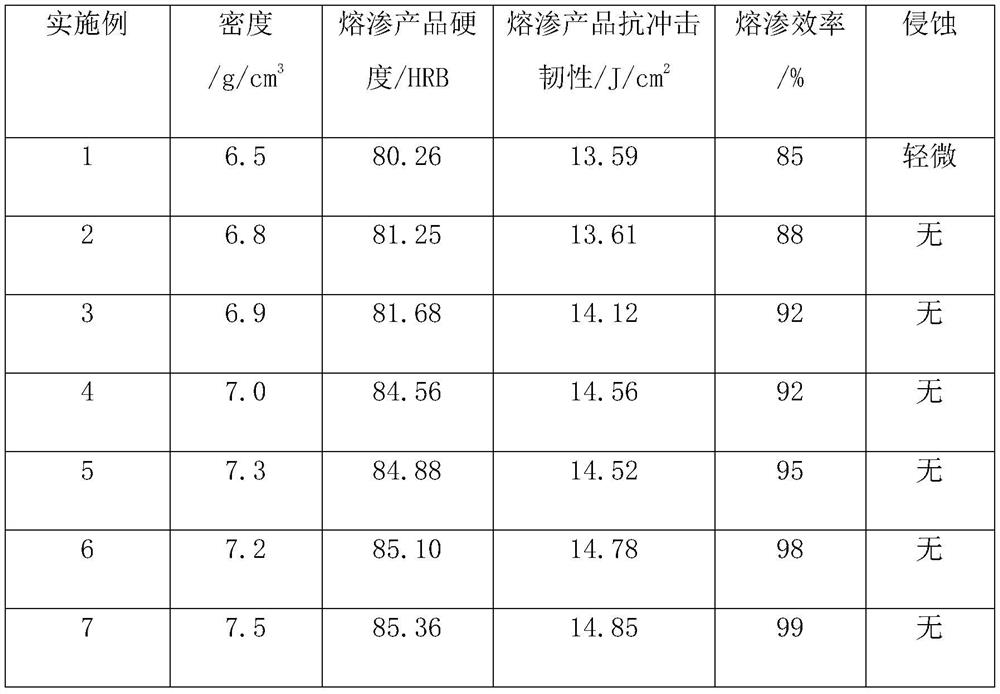

Examples

Embodiment 1

[0030] Embodiment 1: a kind of preparation method of high infiltration rate copper infiltrating wire material, comprises the following steps:

[0031] S1. Ingredients

[0032] In terms of weight percentage, weigh Ni 0.05%, Mn 0.1%, Fe 1%, Zn 1%, and the balance is Cu; then Ni, Mn, Fe, Zn and Cu are mechanically mixed for 15 minutes to obtain a mixture;

[0033] S2, vacuum melting

[0034] Put the mixture obtained in step S1 into the crucible of the vacuum melting furnace, and then evacuate the vacuum degree in the vacuum melting furnace to 3×10 3 Pa, control the smelting current to 1200A, and the smelting power to 5KW, then refine at 1250°C for 10 minutes, and keep it warm for 5 minutes to obtain an alloy solution;

[0035] S3, casting, out of the oven

[0036] Clean the surface of the mold without impurities and oil stains, then preheat the sprue embedded with the ceramic filter plate to 1100°C, and finally pour the alloy solution obtained in step S2 into the sprue, and th...

Embodiment 2

[0045] Embodiment 2: a kind of preparation method of high infiltration rate copper infiltrating wire material, comprises the following steps:

[0046] S1. Ingredients

[0047] In terms of weight percentage, take Ni 0.25%, Mn 0.5%, Fe 2%, Zn 3%, and the balance is Cu; then Ni, Mn, Fe, Zn and Cu are mechanically mixed for 20min to obtain a mixture; The mixed material is sent to the hydrogen reduction furnace for diffusion, the diffusion temperature is controlled at 300°C, and the diffusion time is 50 minutes. Through the diffusion treatment of the mixed material, the erosion of the prepared copper infiltrated wire on the infiltrated base material is reduced, and the workpiece is improved. Forming effect and depth of copper infiltration;

[0048] S2, vacuum melting

[0049] Put the mixture obtained in step S1 into the crucible of the vacuum melting furnace, and then evacuate the vacuum degree in the vacuum melting furnace to 5×10 3 Pa, control the smelting current to 1400A, an...

Embodiment 3

[0060] Embodiment 3: a kind of preparation method of high infiltration rate copper infiltrating wire material, comprises the following steps:

[0061] S1. Ingredients

[0062] In terms of percentage by weight, weigh Ni 0.5%, Mn 1%, Fe 3%, Zn 5%, and the balance is Cu; then Ni, Mn, Fe, Zn and Cu are mechanically mixed for 35 minutes to obtain a mixture;

[0063] S2, vacuum melting

[0064] Put the mixture obtained in step S1 into the crucible of the vacuum melting furnace, and then evacuate the vacuum degree in the vacuum melting furnace to 6×10 3 Pa, control the smelting current to 1600A, and the smelting power to 8KW, then refine at 1280°C for 20 minutes, and heat-preserve for 15 minutes to obtain an alloy solution; heat the alloy solution to 850°C, heat-insulate for 15 minutes, and then heat up to 1050°C , heat preservation treatment for 10 minutes, and finally heat the temperature to 300°C at a rate of 8°C / min. By performing the above operations on the alloy solution, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com