Powder for infiltration

A powder and infiltration technology, applied in the field of powder for infiltration, can solve the problem of high infiltration rate and other problems, and achieve the effect of increasing density, excellent infiltration, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

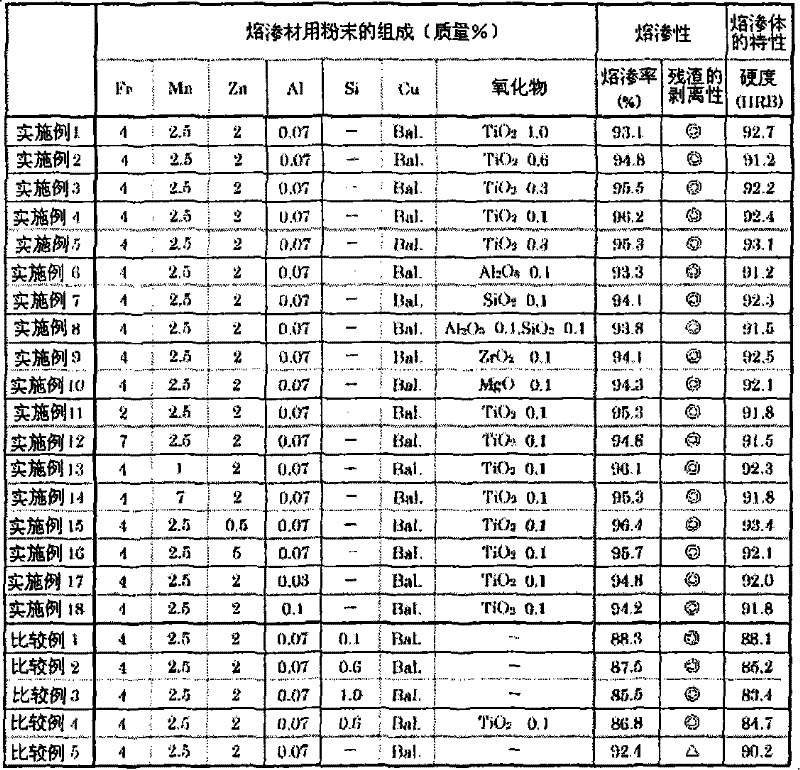

[0026] As a base material, the following green compact was used: 13.7 g of a mixed powder in which 0.8% of zinc stearate (zinc stearate) was added to iron-1.5% copper-1% carbon was molded into a prism shape of 30×12 mm, and Make its density reach 6.3g / cm 3 . As the infiltrating material, the following powder compact is used: TiO with an average particle size of 0.5 μm is added to the powder of copper-4% iron-2.5% manganese-2% zinc-0.07% aluminum produced by the atomization method 2 1.0% powder, and 3.15 g of this mixed powder (the amount of infiltrated material of 80 vol% relative to the pores of the substrate) was formed into a prism shape of 30×12 mm at a pressure of 500 MPa.

[0027] The infiltration material compact is mounted on the substrate compact and a stage of infiltration is performed. After dewaxing by heating at 550°C for 30 minutes, it was heated at 1110°C for 30 minutes. The atmosphere in the sintering furnace was a mixed gas atmosphere in which the ratio of ...

Embodiment 2

[0029] As the substrate, the substrate produced by the same method as in Example 1 was used. As the infiltrated material, a green compact is used in which TiO with an average particle size of 0.5 μm is added to a powder of copper-4% iron-2.5% manganese-2% zinc-0.07% aluminum produced by the atomization method 2 0.6% powder, and 3.15 g of this mixed powder (the amount of infiltrated material of 80 vol% relative to the pores of the substrate) was molded into a prism shape of 30×12 mm at a pressure of 500 MPa. The above-mentioned green compact was infiltrated in the same manner as in Example 1. The characteristics of the obtained infiltrated body are shown in Table 1 together.

Embodiment 3

[0031] As the substrate, the substrate produced by the same method as in Example 1 was used. As the infiltrated material, a green compact is used in which TiO with an average particle size of 0.5 μm is added to a powder of copper-4% iron-2.5% manganese-2% zinc-0.07% aluminum produced by the atomization method 2 0.3% powder, and 3.15 g of this mixed powder (the amount of infiltrated material of 80 vol% relative to the pores of the base material) was formed into a prism shape of 30×12 mm at a pressure of 500 MPa. The above-mentioned green compact was infiltrated in the same manner as in Example 1. The characteristics of the obtained infiltrated body are shown in Table 1 together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com