Handle

A handle and plug technology, applied in the handle field, can solve the problems of the transducer and handle becoming larger, the performance loss of the transducer, etc., so as to reduce the feeling of the handle shaking, reduce performance loss, and reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

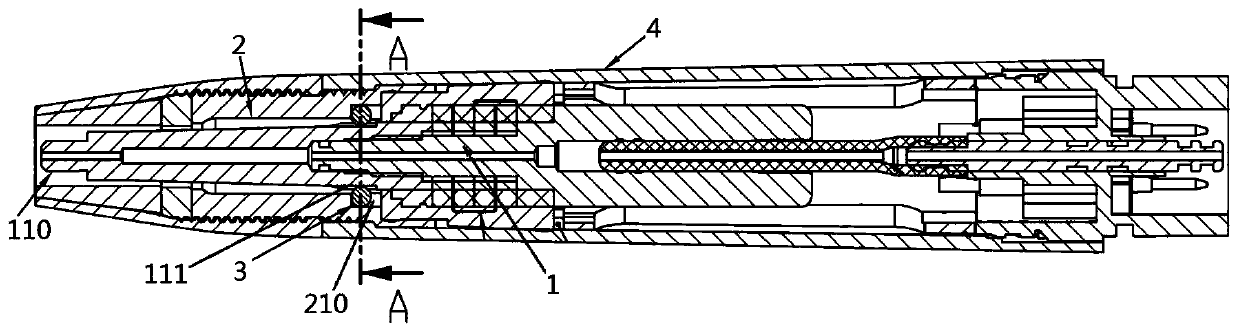

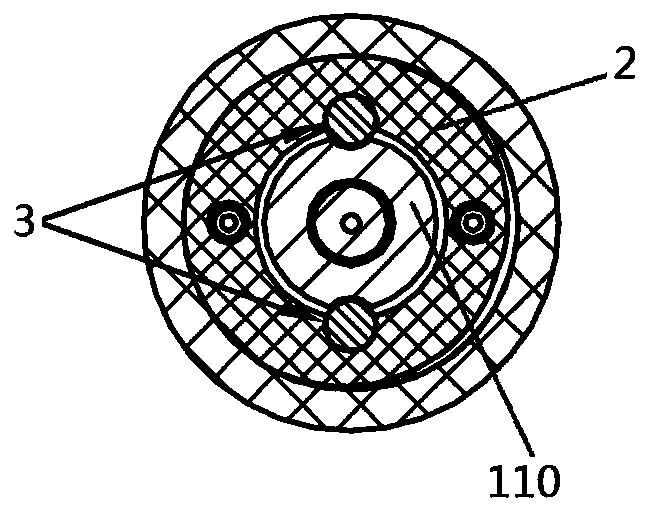

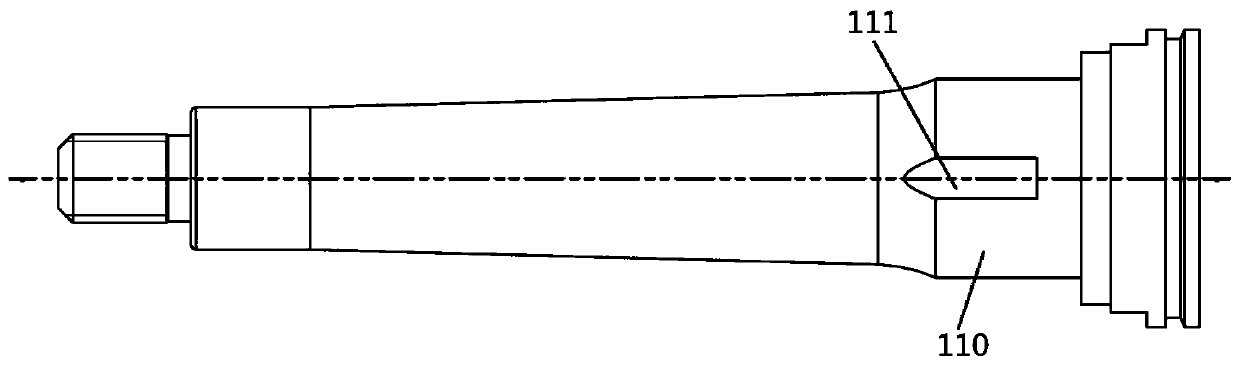

[0022] Such as Figure 1 to Figure 5 As shown, a handle at least includes a transducer 1, a plug 2 and a marble 3, the plug 2 is sleeved on the horn 110 of the transducer 1, and the horn 110 and the plug 2 There is at least one cavity, the cavity is composed of a groove a111 on the outer wall of the horn 110 and a groove b210 on the inner wall of the plug 2, a marble 3 is built in the cavity, and the bullet in the cavity The bead 3 is simultaneously in the groove a111 and the groove b210 constituting the cavity.

Embodiment 2

[0023] Example 2, such as Figure 1 to Figure 5 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1, which is specifically as follows:

[0024] The difference between the radius of the arc cut by the groove a111 in the radial direction and the radius of the marble 3 is greater than 0.05 mm, which facilitates the loading and unloading of the marble 3 .

Embodiment 3

[0025] Example 3, such as Figure 1 to Figure 5 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1 or 2, which is specifically as follows:

[0026] The arc center angle of the arc cut radially by the groove b210 is greater than 180 degrees, and the diameter of the marble 3 is greater than the chord length of the arc cut radially by the groove b210, which can ensure that the marble 3 will not slip from the plug after the installation is completed. 2, and the groove a111 can be an arc-shaped groove, U-shaped groove, V-shaped groove or square groove, etc. If it is an arc-shaped groove, the arc center angle can be any angle, as long as the horn can be realized 110 and the pinball 3 are mutually limited. In practice, the groove b210 and the groove a111 are both arc-shaped grooves, and the angles of their arc centers are preferably 223° and 94° respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com