Limestone powder storage bin

A limestone powder and storage bin technology, applied in the field of limestone, can solve problems such as unloading, easy blockage, and inability to measure powder level, so as to improve feeding efficiency and ensure normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

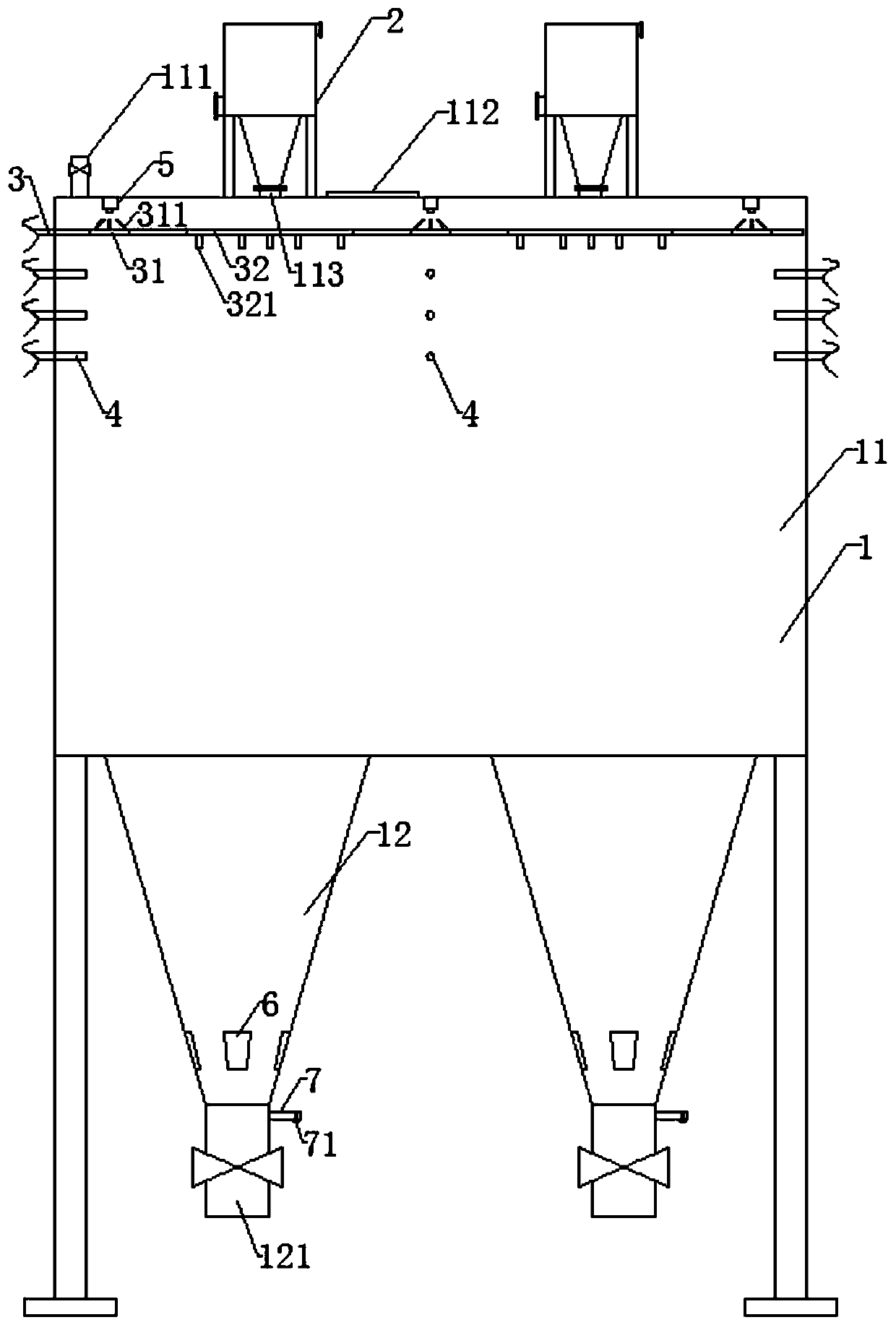

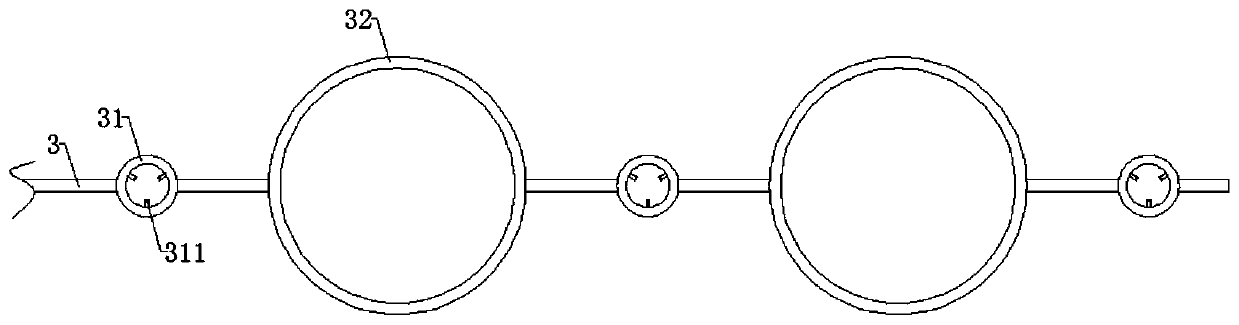

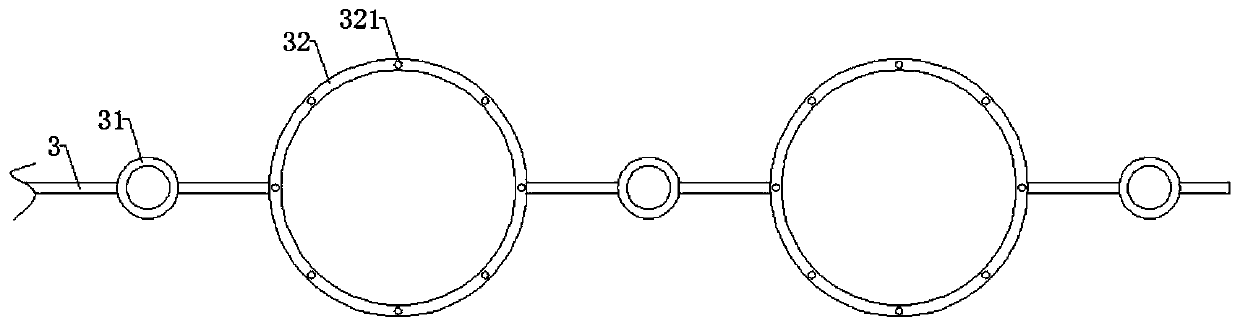

[0026] Such as figure 1 , 2 As shown in and 3, a limestone powder storage silo includes a cylinder 1 and a cone 2, the top of the cylinder 1 is provided with a pressure and vacuum relief valve 111, a manhole 112 and at least one feed port 113, the feed A pulse bag filter 2 connected to it is arranged above the mouth 113, and at least one ultrasonic liquid level gauge 5 is arranged at the top of the cylinder body 1. The first blowing pipe 3, one end of the first blowing pipe 3 is connected to the external air source through the cylinder body 1, and the other end is closed and arranged, and the first blowing branch pipe pointing to the ultrasonic liquid level gauge 5 is arranged on the first blowing pipe 3 311 and the second blowing branch pipe 321 arranged vertically downward, at least one set of second blowing pipe 4 is arranged below the first blowing pipe 3, one end of the second blowing pipe 3 passes through the cylinder 1 and is connected to an external air source, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com