A method and system for precise proportioning of cutting fluid based on information feedback

An information feedback, cutting fluid technology, applied in chemical instruments and methods, mixer accessories, mixers, etc., can solve the lack of concentration detection cutting fluid ratio work, can not guarantee the cutting fluid tank concentration, can not effectively reflect the concentration change, etc. problems, to achieve the effect of realizing efficiency and unit production efficiency, improving the comprehensive utilization rate of equipment, and high comprehensive utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

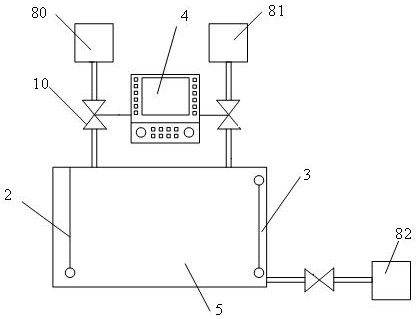

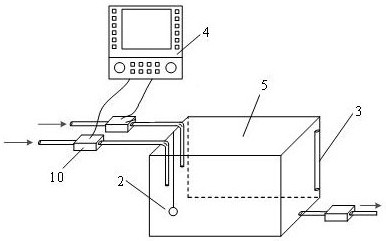

[0035] A cutting fluid precise proportioning system based on information feedback, such as Figure 2-3 As shown, it includes a cutting fluid tank 5, a waste liquid tank 82, a cutting liquid unit 80, a tap water unit 81, a solenoid valve 10, a concentration detector 2, a liquid level detector 3, and a numerical control unit 4. The top of the cutting fluid tank 5 The cutting stock solution unit 80 and the tap water unit 81 are respectively connected through the aqueduct, and the bottom is connected with the waste liquid tank 82 through the aqueduct; the aqueduct is provided with a solenoid valve 10, and the inside of the cutting fluid tank 5 is respectively provided with a concentration detector. 2. The liquid level detector 3 , the liquid level detector 3 is arranged along the side wall of the cutting fluid tank 5 , and the concentration detector 2 is arranged at the bottom of the cutting fluid tank 5 . The numerical control unit 4 is respectively connected with the solenoid va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com