Device for coating cable with semi-conductive graphite

A coating equipment, semi-conductive technology, used in coatings, devices for coating liquids on surfaces, spray booths, etc. Improve the use effect, ensure the effect of physical and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

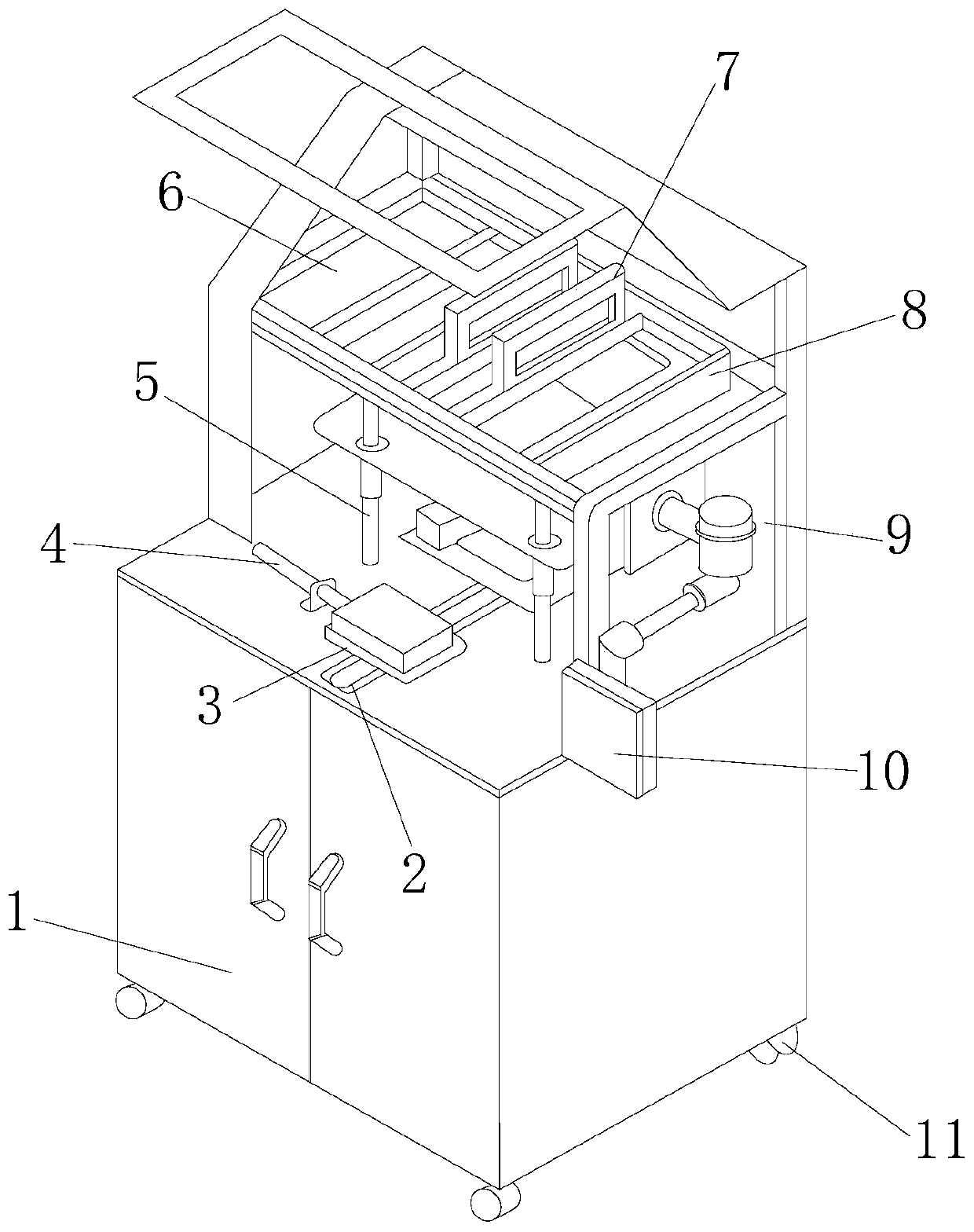

[0032] see figure 1 , the present invention provides a technical solution: a cable semi-conductive graphite coating equipment, its structure includes a body 1, a fixing device 2, a slide rail 3, a material receiving tray 4, a nozzle 5, a moving frame 6, a coater 7, Blowing device 8, receiving bin 9, display screen 10, universal wheels 11, universal wheels 11 are provided on the four sides of the bottom of the body 1, and the bottom of the slide rail 3 is embedded in the middle position of the body 1 , the slide rail 3 is connected with the fixing device 2, the material receiving tray 4 slides back and forth on the slide rail 3, and the end of the slide rail 3 is connected to the inside of the receiving bin 9, and the receiving bin 9 is located in a mobile The bottom of the frame 6, the nozzle 5 is connected to the mobile frame 6, the nozzle 5 slides left and right at the bottom of the mobile frame 6, the top of the mobile frame 6 fits with the applicator 7, and the applicator...

Embodiment 2

[0039] see figure 1 , the present invention provides a technical solution: a cable semi-conductive graphite coating equipment, its structure includes a body 1, a fixing device 2, a slide rail 3, a material receiving tray 4, a nozzle 5, a moving frame 6, a coater 7, Blowing device 8, receiving bin 9, display screen 10, universal wheels 11, universal wheels 11 are provided on the four sides of the bottom of the body 1, and the bottom of the slide rail 3 is embedded in the middle position of the body 1 , the slide rail 3 is connected with the fixing device 2, the material receiving tray 4 slides back and forth on the slide rail 3, and the end of the slide rail 3 is connected to the inside of the receiving bin 9, and the receiving bin 9 is located in a mobile The bottom of the frame 6, the nozzle 5 is connected to the mobile frame 6, the nozzle 5 slides left and right at the bottom of the mobile frame 6, the top of the mobile frame 6 fits with the applicator 7, and the applicator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com