Environment-friendly automatic residual oil and water discharging separator

An automatic slag removal and oil-water separation technology, applied in liquid separation, separation methods, water pollutants, etc., can solve the problems of reducing the efficiency of separation, damaging the device, hindering the absorption of oil, etc., so as to avoid residue damage and achieve efficient and convenient oil-water separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

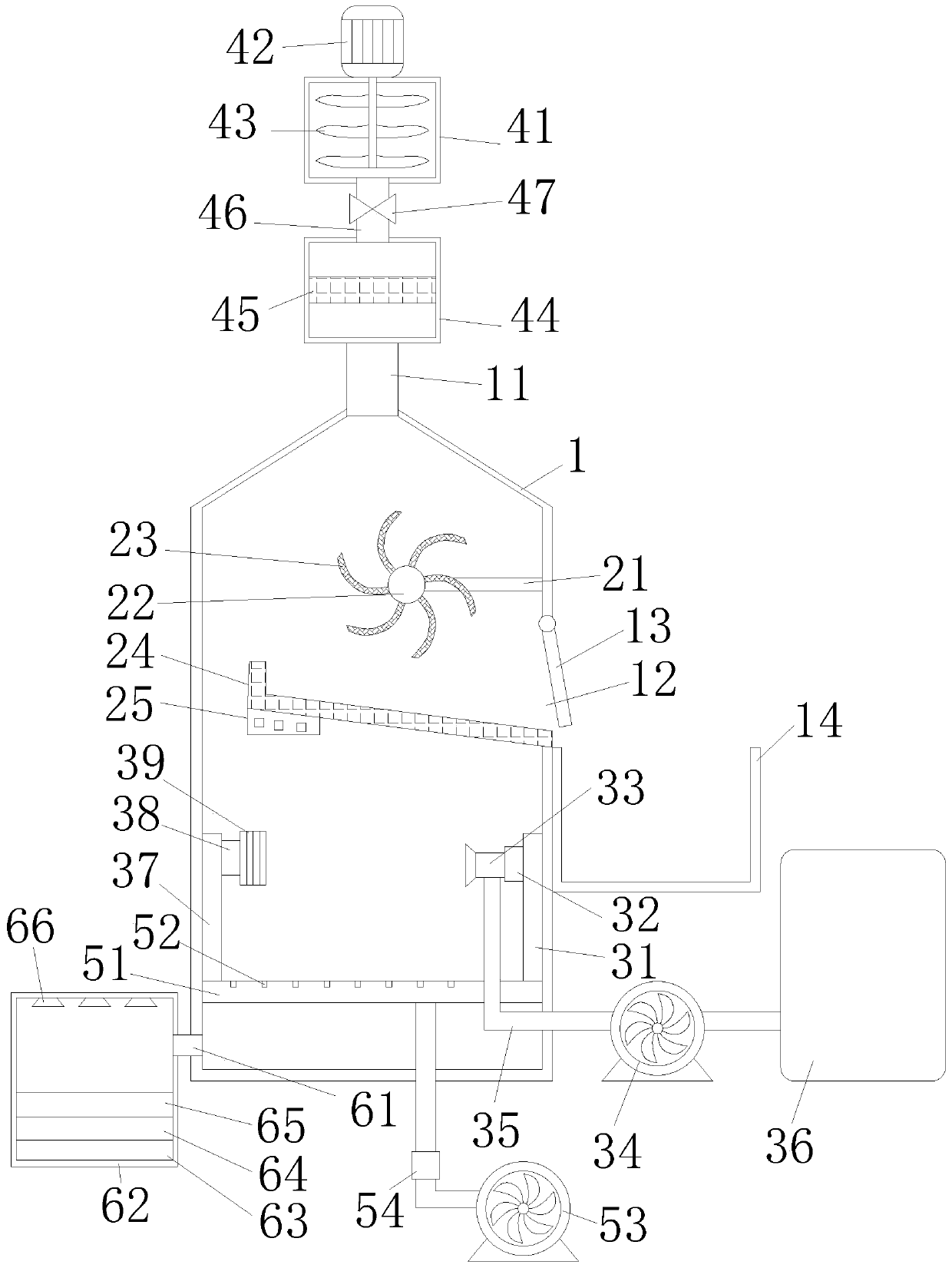

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0021] like figure 1 As shown, an environment-friendly automatic deslagging oil-water separator is provided in the embodiment, including a tower tank 1, a slag removal device, and a separation device. An input pipe 11 is connected to the top of the tower tank 1 . The slag removal device includes a support 21, a bearing 22, a plurality of filter screen plates 23, and a filter frame 24, the support 21 is horizontally fixed on the inner wall of the tower tank 1, the axis of the bearing 22 is fixed on the support 21, and a plurality of filter screen plates 23 It is fixed on the outside of the bearing 22 at equal angles, and the filter screen plate 23 is bent and set, the filter frame 24 is set obliquely, and the lower end of the filter frame 24 is connected with the right side wall of the tower tank 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com