Water conservancy gate

A gate and water conservancy technology, applied in the field of water conservancy, can solve the problems of normal use of water conservancy gates, gaps in water channels, adhesion of silt and stones, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

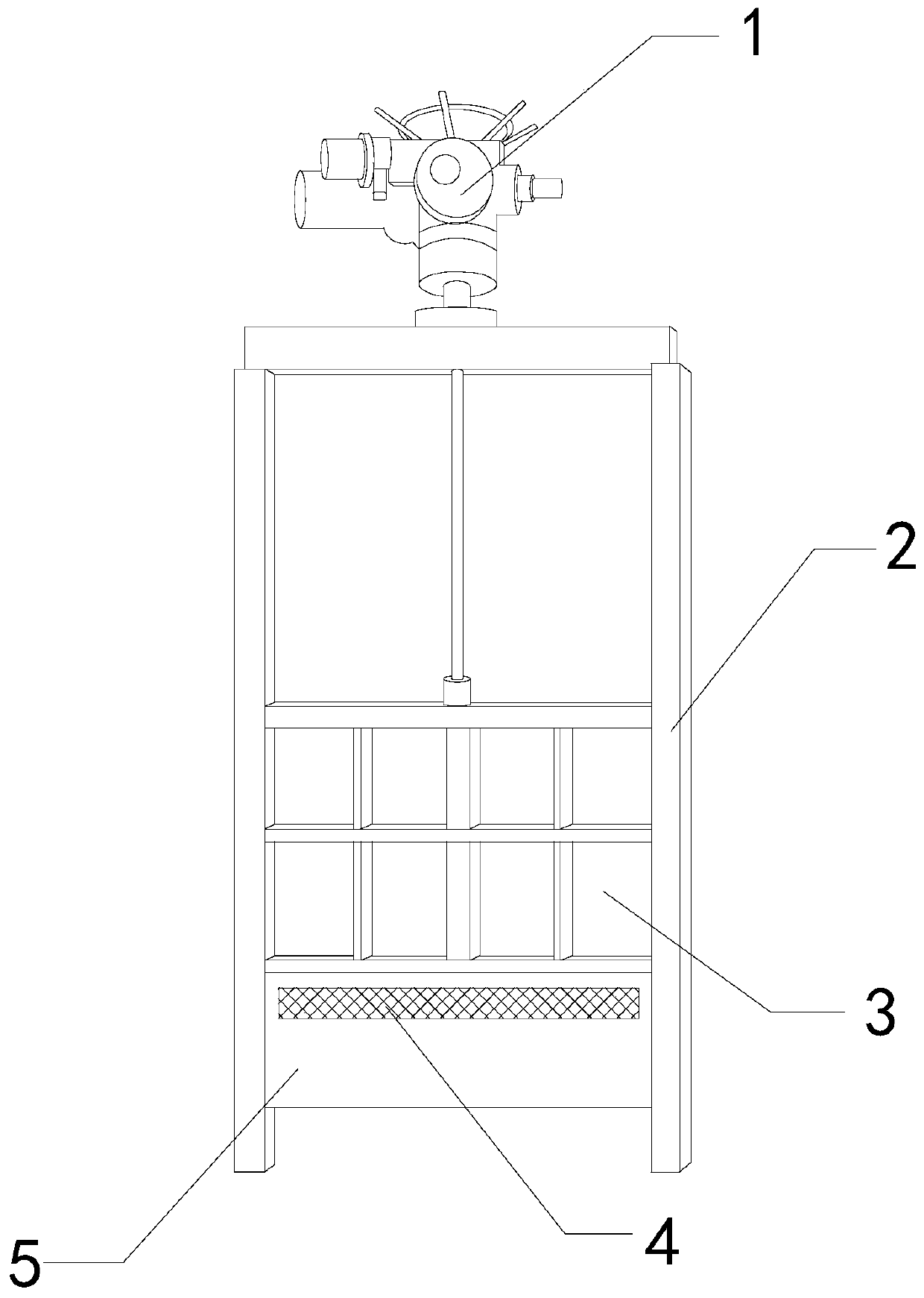

[0027] For example figure 1 -example Figure 5 Shown:

[0028] The invention provides a water conservancy gate, the structure of which includes a driver 1, an outer frame 2, a gate 3, a water permeable opening 4, and a mud cleaning mechanism 5. The driver 1 is connected to the gate 3 through the outer frame 2, and the gate 3 is connected to the outer The inner wall of the frame 2 is fitted with a gap, and the permeable port 4 and the mud-clearing mechanism 5 are an integrated structure, and the mud-clearing mechanism 5 is embedded and fixed at the bottom of the gate 3 .

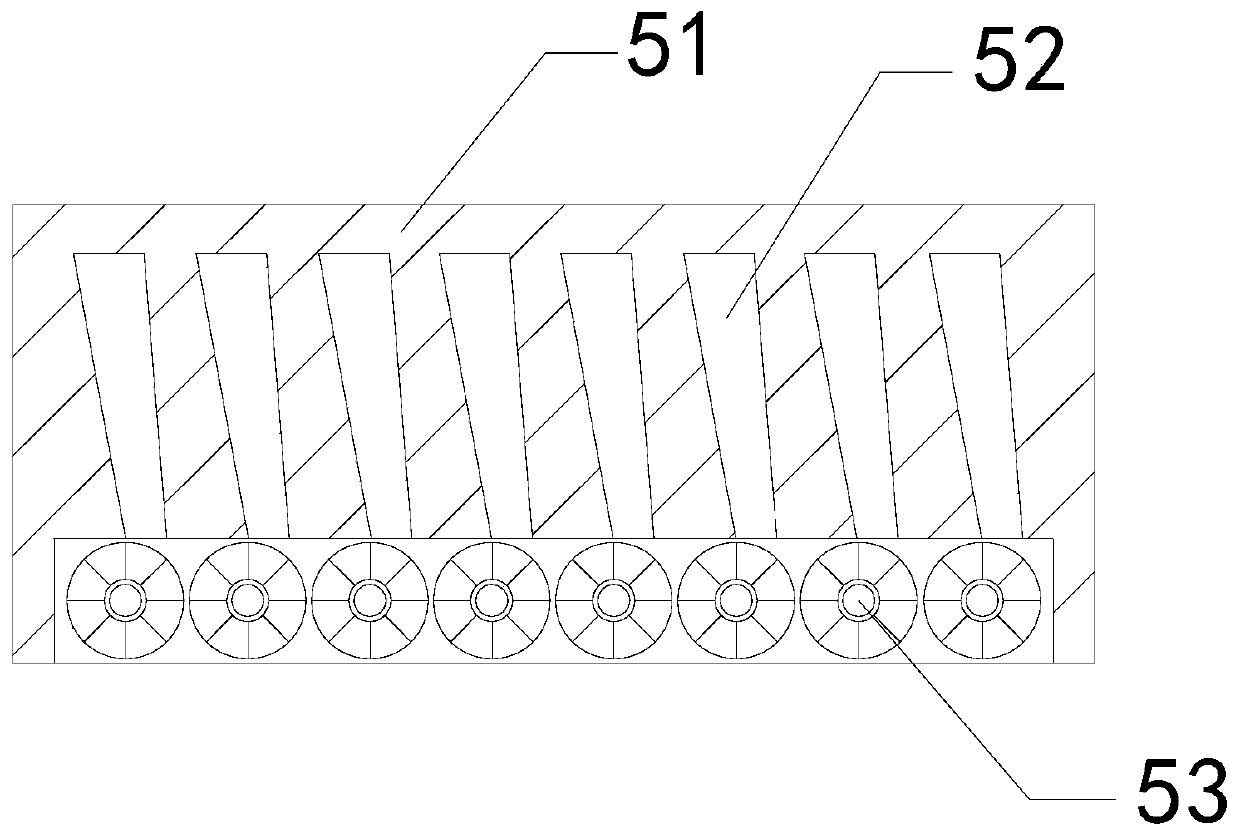

[0029] Wherein, the mud cleaning mechanism 5 includes a housing 51, a water storage tank 52, and a cleaning roller 53. The water storage tank 52 is embedded in the inner position of the housing 51, and the cleaning roller 53 is movable with the inner wall of the housing 51 near the lower end. Together, the water storage tank 52 has an inverted trapezoidal structure, which can enhance the water pressure of t...

Embodiment 2

[0036] For example Figure 6 -example Figure 8 Shown:

[0037] Wherein, the opening and closing plate b3 includes a rolling column b31, a baffle b32, a sliding groove b33, and a bottom plate b34. The rolling column b31 is movably engaged with the sliding groove b33, and the baffle b32 is embedded and connected with the bottom plate b34. The sliding groove b33 and the baffle b32 are integrated structures, and the outer surface of the rolling column b31 is always in contact with the upper surface of the bottom plate b34, and can remove a small amount of silt adhered to the surface of the bottom plate b34 through the promotion of water flow.

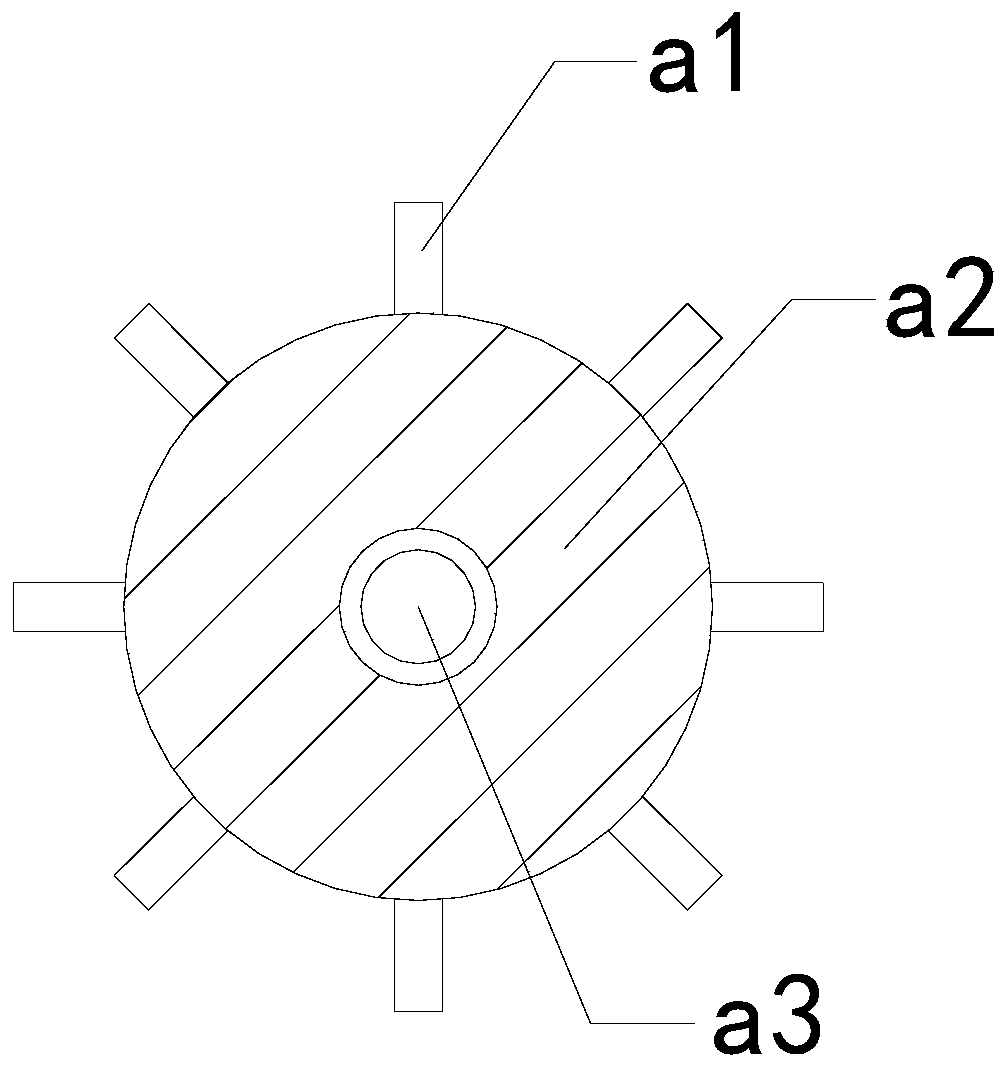

[0038]Wherein, the rolling column b31 includes a scraper c1, a cleaning block c2, a receiving column c3, an engaging roller c4, and a scraping mechanism c5. The scraper c1 is embedded in the outer surface of the receiving column c3, and the cleaning block c2 is installed Between the two adjacent scrapers c1, the engaging roller c4 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com