Heat accumulation type radiant tube burner

A regenerative radiant tube and radiant tube technology, which can be applied to burners, combustion methods, combustion types, etc., can solve problems such as large nitrogen oxide emissions, unfavorable environmental protection, and non-compliance with emission standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

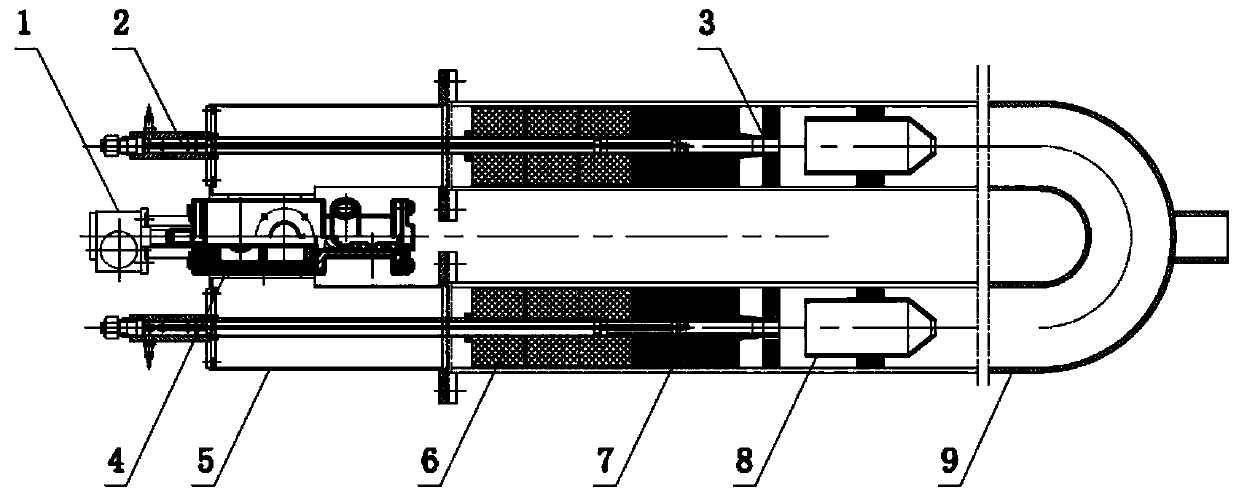

[0030] figure 1 It is a structural schematic diagram of a regenerative radiant tube burner according to an embodiment of the present invention, please refer to figure 1 , a regenerative radiant tube burner provided by an embodiment of the present invention, the regenerative radiant tube burner includes: a cylinder 1, a reversing valve 4, an air cavity 5, an ignition assembly 2, a heat storage body 6, a jet Disk 3, radiant tube 9, combustion cylinder 8.

[0031] The cylinder 1 is connected with a reversing valve 4, and the cylinder 1 drives the reversing valve 4 to control the gas direction; the reversing valve 4 has an air input end, an exhaust gas output end, and two reversing ports, and the reversing valve 4 The air input end of the reversing valve 4 can be selectively connected with one of the two reversing ports of the reversing valve 4 .

[0032] Specifically, the reversing valve 4 can rotate 90 degrees, and the cylinder 1 pushes the cylinder to move by compression, gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com