Constant-load stress corrosion online observation test device in hydrofluoric acid environment

A technology of stress corrosion and test equipment, which is applied in the direction of measuring equipment, using stable tension/pressure to test material strength, weather resistance/light resistance/corrosion resistance, etc., can solve the problem of not being able to realize hydrofluoric acid stress corrosion test equipment, limitations The development of hydrofluoric acid corrosion research and the large stress corrosion test equipment have achieved the effect of compact and simple structure, preventing volatile leakage and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

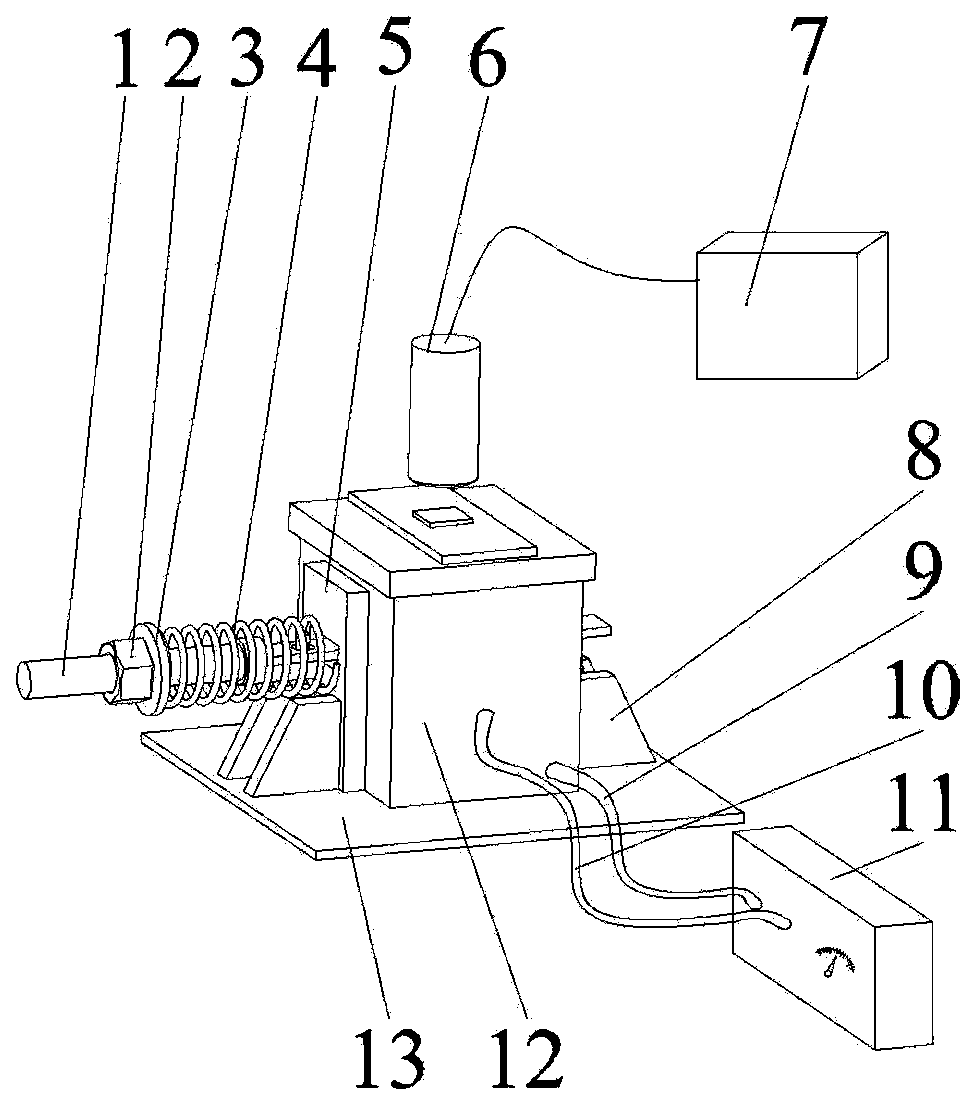

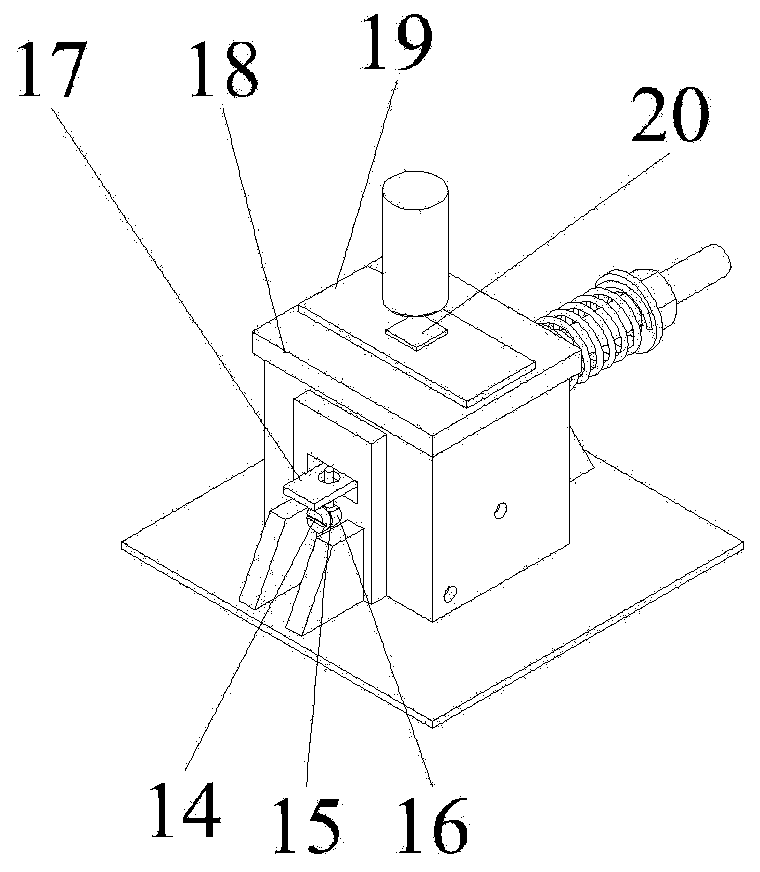

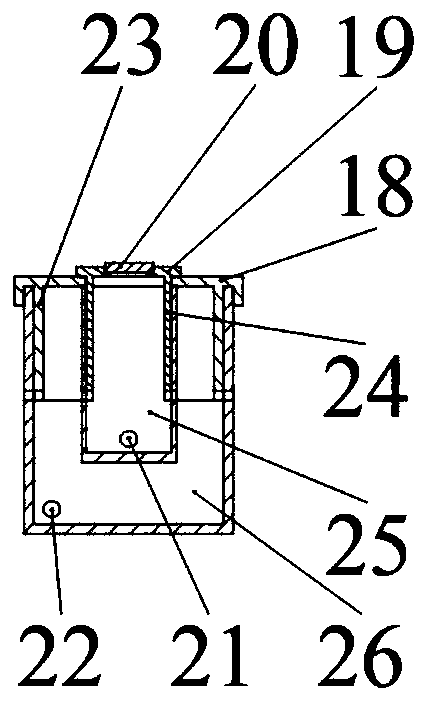

[0031] An on-line observation and test device for constant load stress corrosion under hydrofluoric acid environment. and the outer tank are equipped with hydrofluoric acid corrosion solution, the inner tank and the outer tank are respectively provided with a corrosion tank inner cover 19 and an corrosion tank outer cover 18, and both sides of the corrosion tank are provided with baffles 5, the bottom plate and the baffle plate Support ribs 8 are arranged between them, a transparent observation window 20 is arranged on the inner cover of the corrosion tank, an optical microscope 6 is installed on the transparent observation window, and the optical microscope is externally connected to a computer 7; There is a side hole 28, the sample 17 is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com