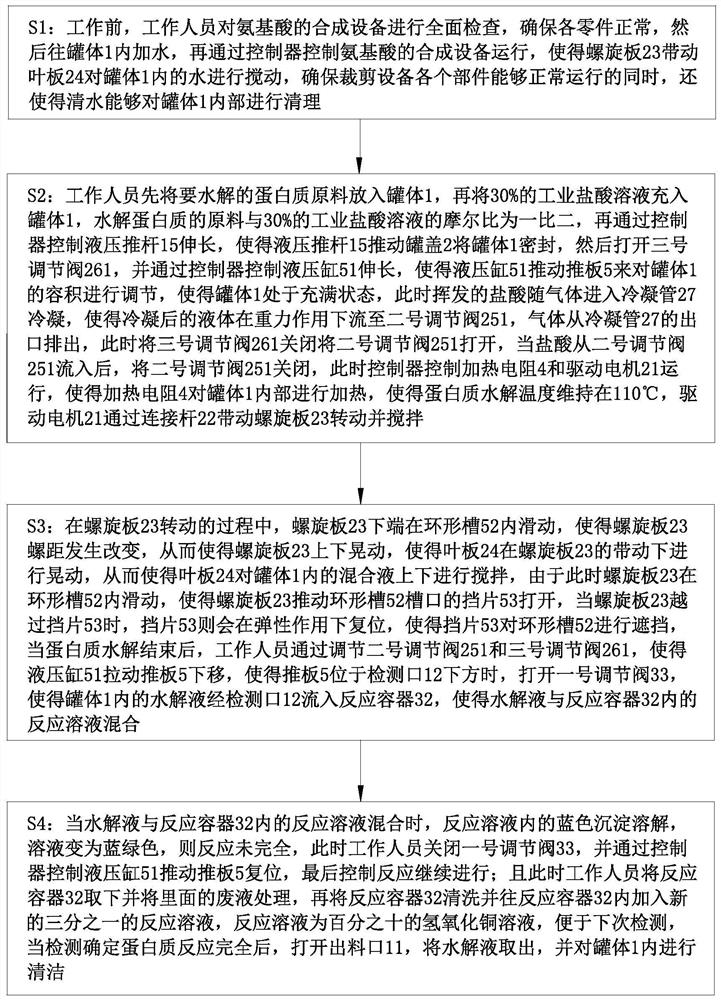

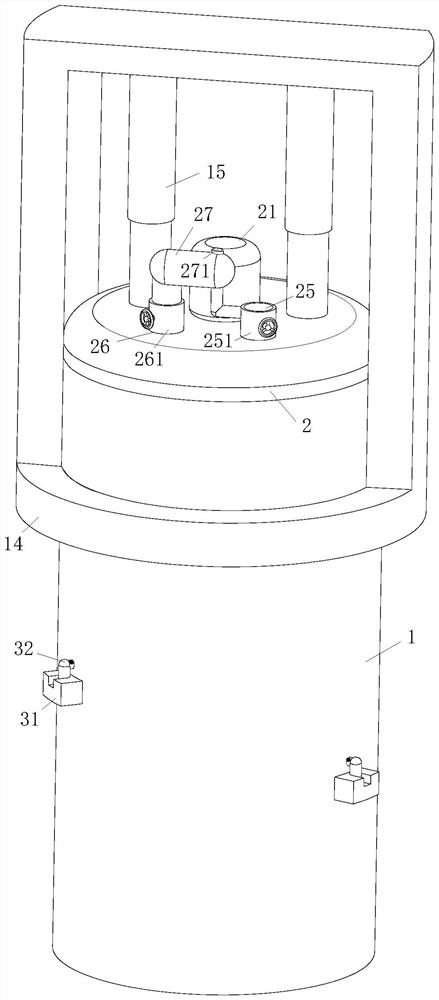

Amino acid synthesis equipment and method

A synthesis equipment and amino acid technology, applied in the synthesis field of amino acid synthesis equipment, can solve the problems such as the detection of protein hydrolyzates, damage to the sealing performance of the tank, and environmental pollution by hydrochloric acid. The effect of accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

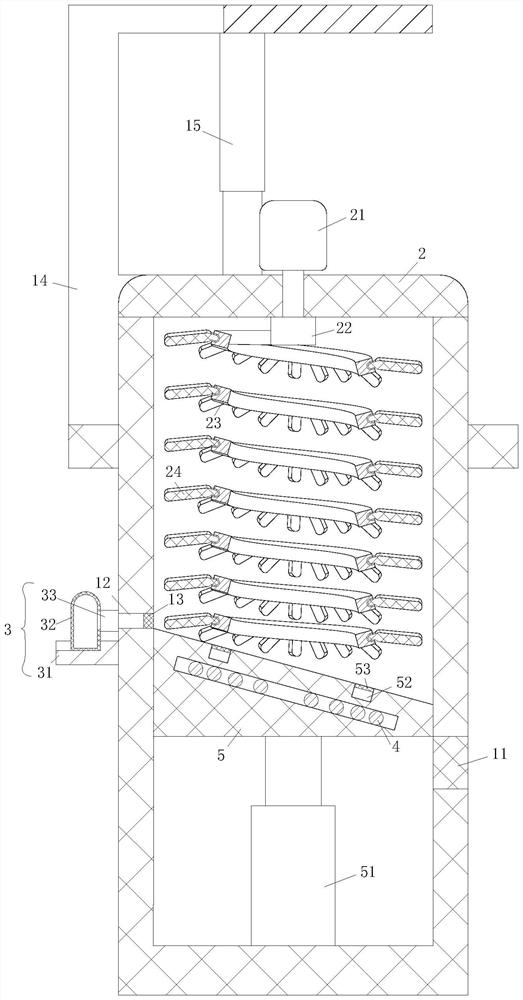

[0033]As an embodiment of the present invention, the side of the spiral plate 23 close to the inner wall of the tank body 1 is hinged with a blade 24; the blade 24 is arranged obliquely, and the upper end surface of the blade 24 is arc-shaped; The device controls the drive motor 21 to drive the spiral plate 23 to rotate, so that the spiral plate 23 drives the blade plate 24 to rotate in the liquid. During the rotation of the blade plate 24, the mixed solution of protein and hydrochloric acid in the tank body 1 can flow on the blade plate 24 Mixing under the impetus of the inclined plane makes hydrochloric acid accelerate the hydrolysis of the protein. Since the blade plate 24 is inclined, so when the mixed solution is pushed by the blade plate 24, the mixed solution will flow upward along the upper end surface and the lower end surface of the blade plate 24, and Because the upper end surface of the blade plate 24 is arc-shaped, the flow velocity of the mixed liquid on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com