Plasma display screen of PDP discharge electrode

A plasma display and discharge electrode technology, applied in discharge tubes, gas-filled discharge tubes, circuits, etc., can solve problems such as internal air expansion, electrode heating, glass breakage, etc., to expand space, increase speed, and prevent equipment damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

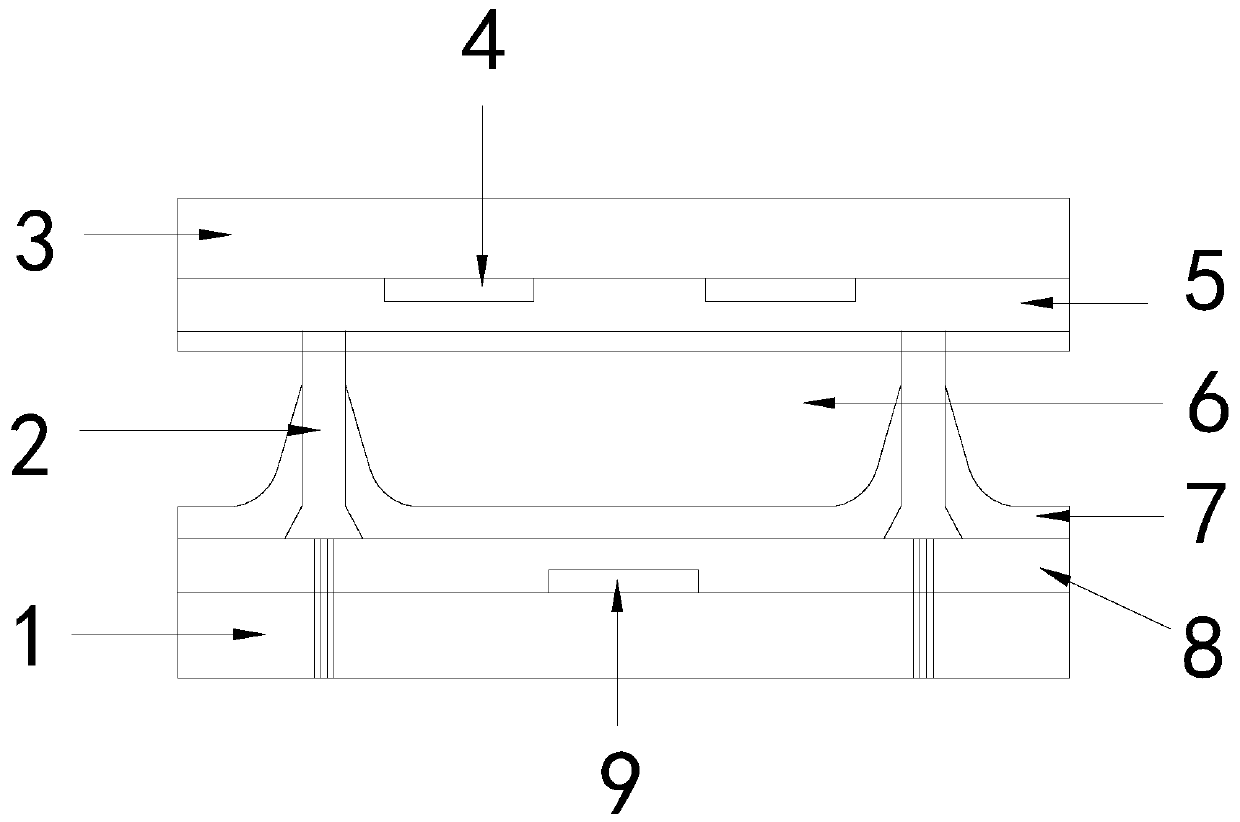

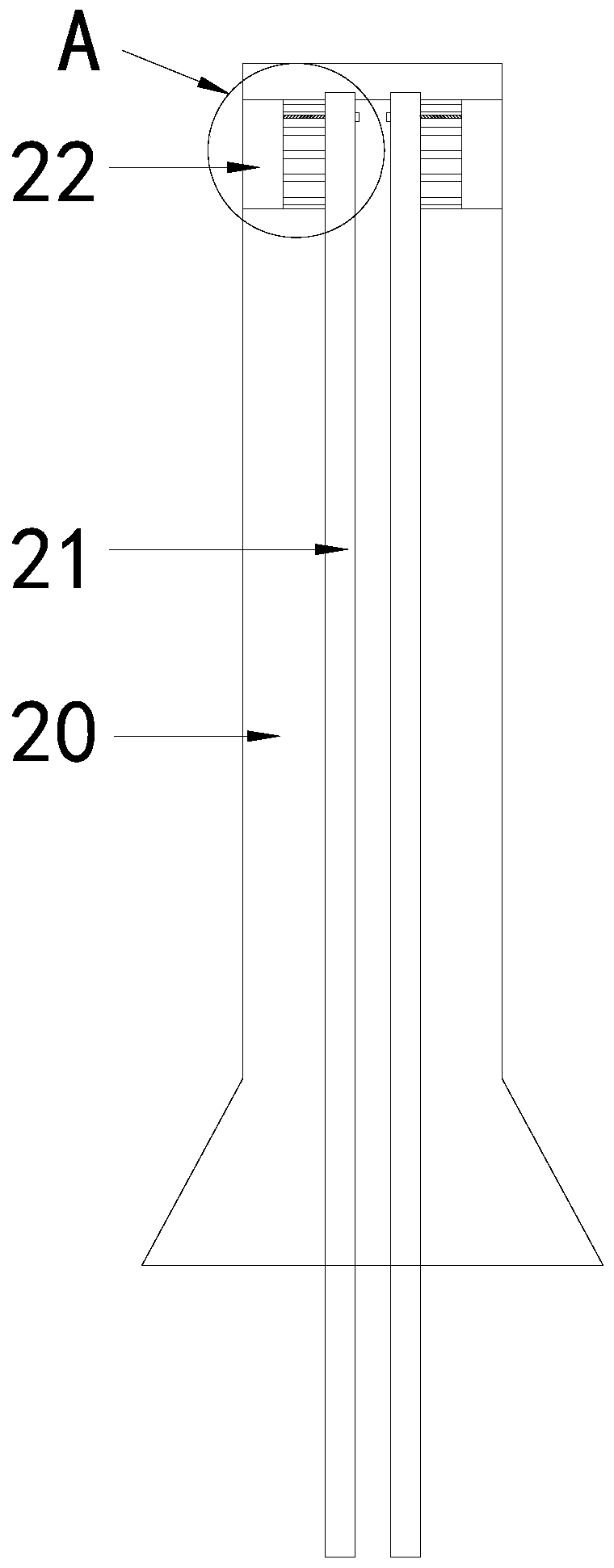

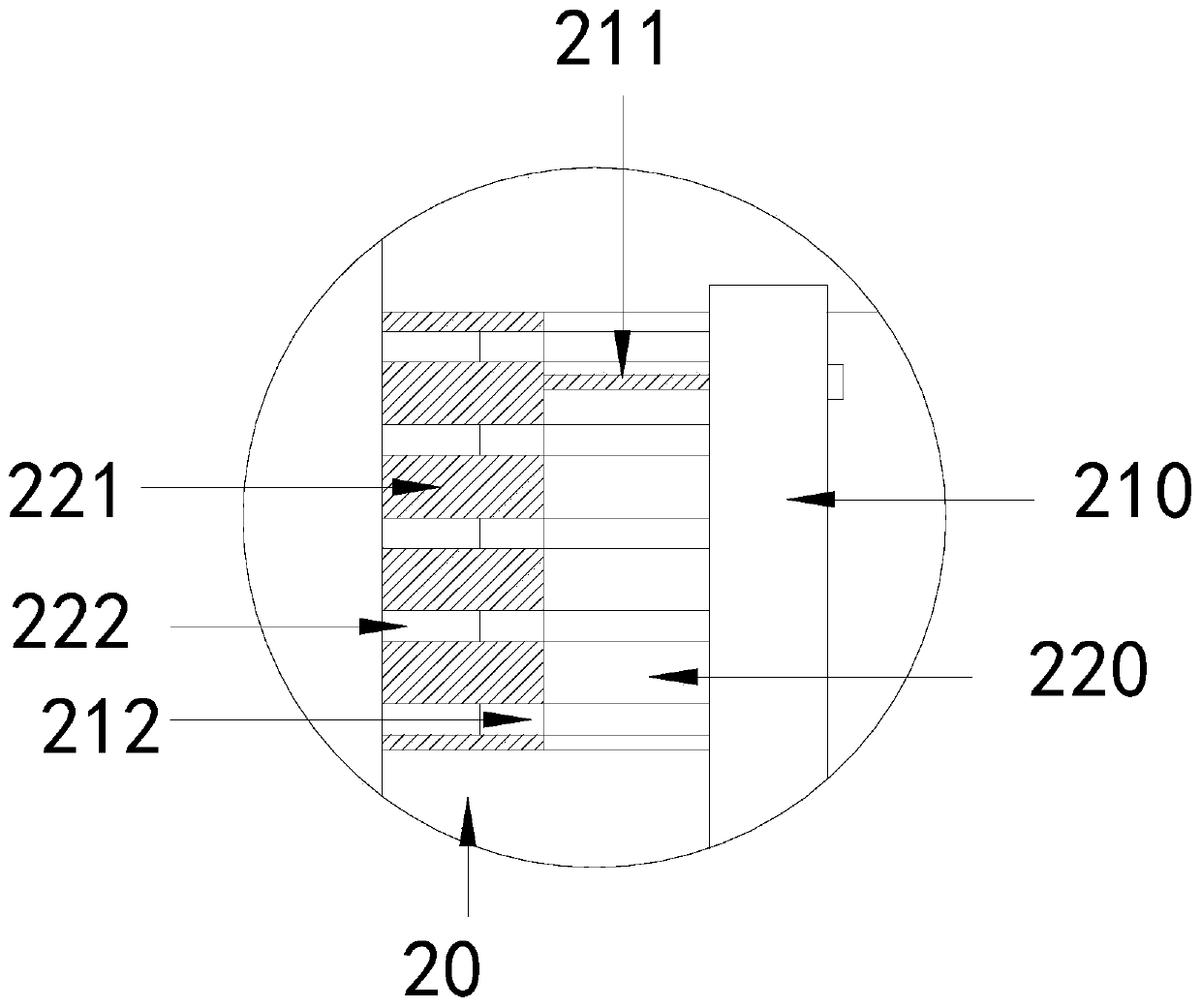

[0027] see Figure 1-5 , the present invention provides a PDP discharge electrode plasma display screen technical scheme: its structure includes a back glass 1, a barrier 2, a front glass 3, a transparent electrode 4, a phosphor 5, an addressing electrode 6, the back glass 1 and the front The glass 3 is parallel, the back glass 1 is provided with phosphors 5 and separated by a barrier 2, the barrier 2 is connected between the front glass 3 and the back glass 1, and the front glass 3 is provided with a transparent electrode 4 , the back glass 1 is provided with an addressing electrode 6, and the barrier 2 includes a main body 20, a cooling structure 21, and a movable structure 22. One end of the main body 20 close to the front glass 3 is provided with movable structures 22 on both sides, so The cooling structure 21 is arranged in the middle of the main body 20 , the movable structure 22 includes a movable slot 220 and a moving block 221 , the movable slot 220 is arranged at one...

Embodiment 2

[0030] see Figure 1-5 , the present invention provides a PDP discharge electrode plasma display screen technical scheme: its structure includes a back glass 1, a barrier 2, a front glass 3, a transparent electrode 4, a phosphor 5, an addressing electrode 6, the back glass 1 and the front The glass 3 is parallel, the back glass 1 is provided with phosphors 5 and separated by a barrier 2, the barrier 2 is connected between the front glass 3 and the back glass 1, and the front glass 3 is provided with a transparent electrode 4 , the back glass 1 is provided with an addressing electrode 6, and the barrier 2 includes a main body 20, a cooling structure 21, and a movable structure 22. One end of the main body 20 close to the front glass 3 is provided with movable structures 22 on both sides, so The cooling structure 21 is arranged in the middle of the main body 20 , the movable structure 22 includes a movable slot 220 and a moving block 221 , the movable slot 220 is arranged at one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com