High-load electrode, preparation method and lithium ion battery thereof

A high-load, electrode technology, applied in batteries, battery electrodes, secondary batteries, etc., can solve the problems of battery gram capacity cycle and low-temperature discharge performance degradation, poor electrolyte infiltration, and increased internal resistance of pole pieces , to achieve the effect of improving polarization, reducing the degree of separation, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

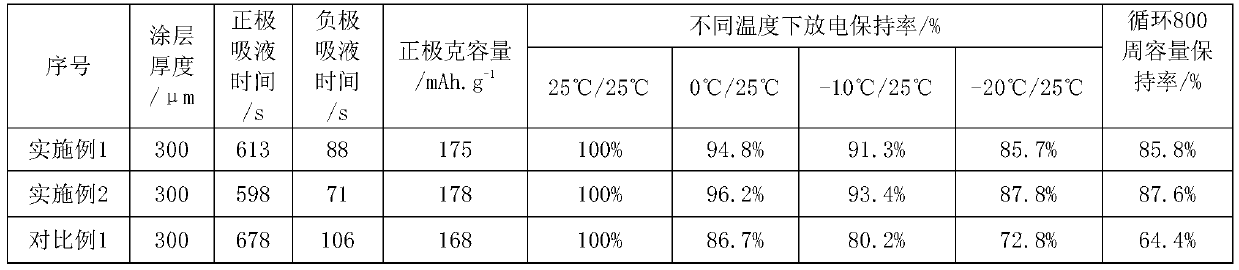

Examples

Embodiment 1

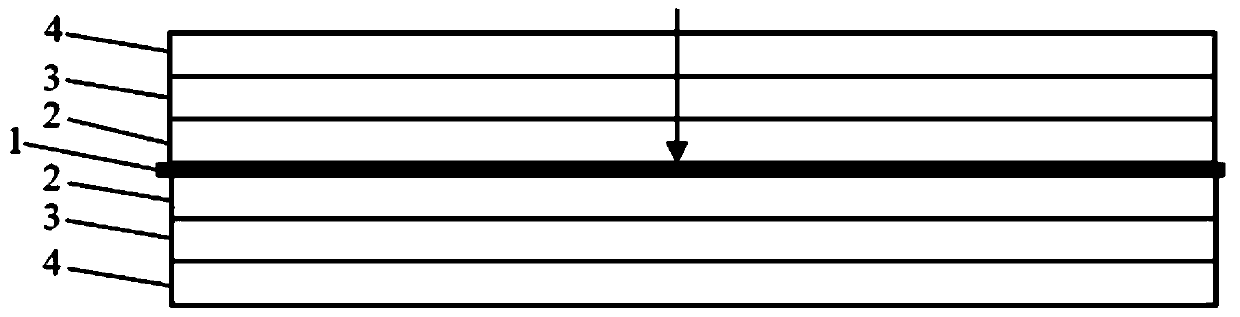

[0022] Production of positive and highly loaded pole pieces:

[0023] a. Pour positive electrode active material NCM622, conductive agent 1 (SP), conductive agent 2 (CNTs), and binder (PVDF) into N-methyl-2-pyrrolidone in a weight ratio of 94.6:1.6:1.6:2.2, Mix and stir evenly to prepare positive electrode slurry A with a solid content of 75%;

[0024] b. Pour positive electrode active material NCM622, conductive agent 1 (SP), conductive agent 2 (CNTs), and binder (PVDF) into N-methyl-2-pyrrolidone in a weight ratio of 95.4:1.4:1.4:1.8, Mix and stir evenly to prepare positive electrode slurry B with a solid content of 75%;

[0025] c. Coat the positive electrode slurry A on the aluminum foil current collector, and the total loading of the coating after drying is 50mg / cm 2 , the total thickness is 200 μm, the thickness of the coating after rolling is 180 μm, and the positive electrode sheet A is obtained;

[0026] d. Coat the positive electrode slurry B on the positive elect...

Embodiment 2

[0039] Production of positive and highly loaded pole pieces:

[0040] a. Pour positive electrode active material NCM622, conductive agent 1 (SP), conductive agent 2 (CNTs), and binder (PVDF) into N-methyl-2-pyrrolidone in a weight ratio of 94.4:1.7:1.7:2.2, Mix and stir evenly to prepare positive electrode slurry A with a solid content of 75%;

[0041] b. Pour positive electrode active material NCM622, conductive agent 1 (SP), conductive agent 2 (CNTs), and binder (PVDF) into N-methyl-2-pyrrolidone in a weight ratio of 95.0:1.5:1.5:2.0, Mix and stir evenly to prepare positive electrode slurry B with a solid content of 75%;

[0042] c. Pour positive electrode active material NCM622, conductive agent 1 (SP), conductive agent 2 (CNTs), and binder (PVDF) into N-methyl-2-pyrrolidone in a weight ratio of 95.6:1.3:1.3:1.8, Mix and stir evenly to prepare positive electrode slurry C with a solid content of 75%;

[0043] d. Coat the positive electrode slurry A on the aluminum foil cu...

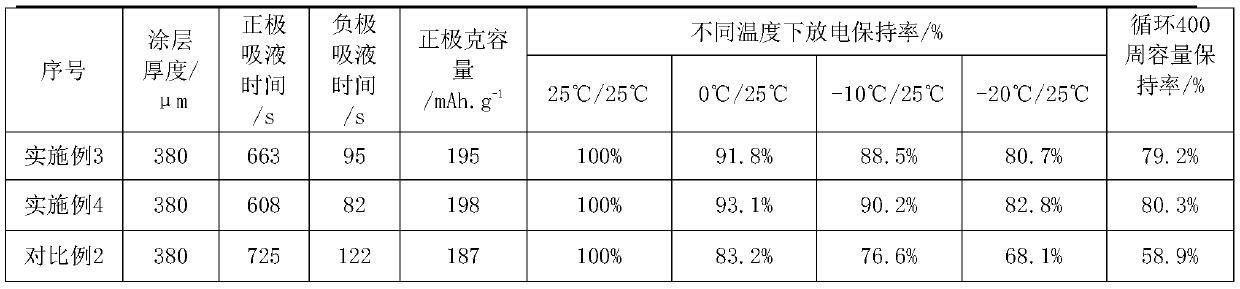

Embodiment 3

[0076] Production of positive and highly loaded pole pieces:

[0077] a. Pour positive active material NCM811, conductive agent 1 (SP), conductive agent 2 (CNTs), and binder (PVDF) into N-methyl-2-pyrrolidone in a weight ratio of 94.4:1.5:1.5:2.6, Mix and stir evenly to prepare positive electrode slurry A with a solid content of 75%;

[0078] b. Pour positive electrode active material NCM811, conductive agent 1 (SP), conductive agent 2 (CNTs), and binder (PVDF) into N-methyl-2-pyrrolidone in a weight ratio of 95.2:1.2:1.2:2.4, Mix and stir evenly to prepare positive electrode slurry B with a solid content of 75%;

[0079] c. Coat the positive electrode slurry A on the aluminum foil current collector, and the total loading of the coating after drying is 63mg / cm 2 , the total thickness is 250 μm, the thickness of the coating after rolling is 220 μm, and the positive electrode sheet A is obtained;

[0080] d. Coat the positive electrode slurry B on the positive electrode sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com