Hydrophilic polyamide reverse osmosis membrane with compact surface as well as preparation method and application thereof

A technology of reverse osmosis membrane and polyamide, used in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as membrane water flux decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

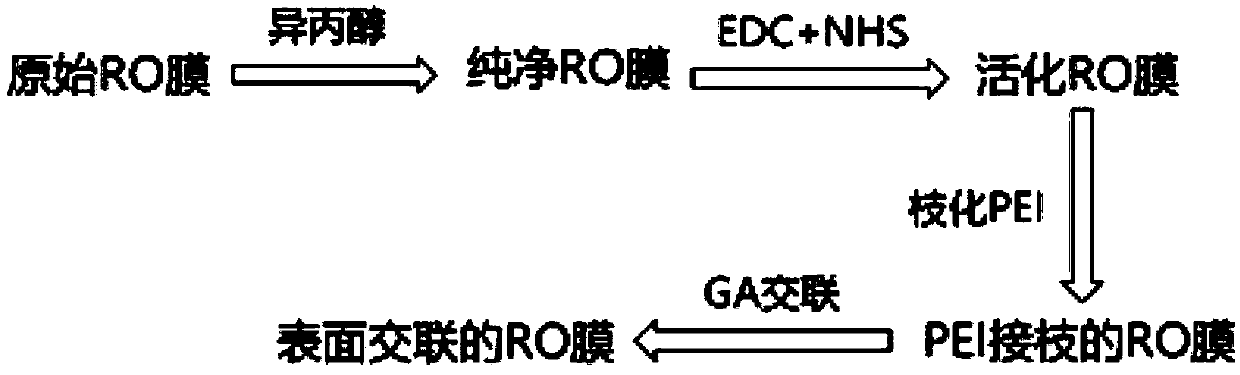

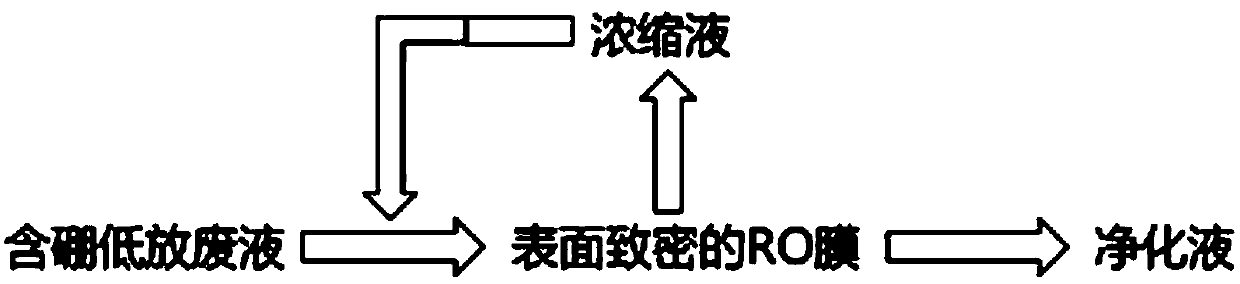

Method used

Image

Examples

Embodiment 1

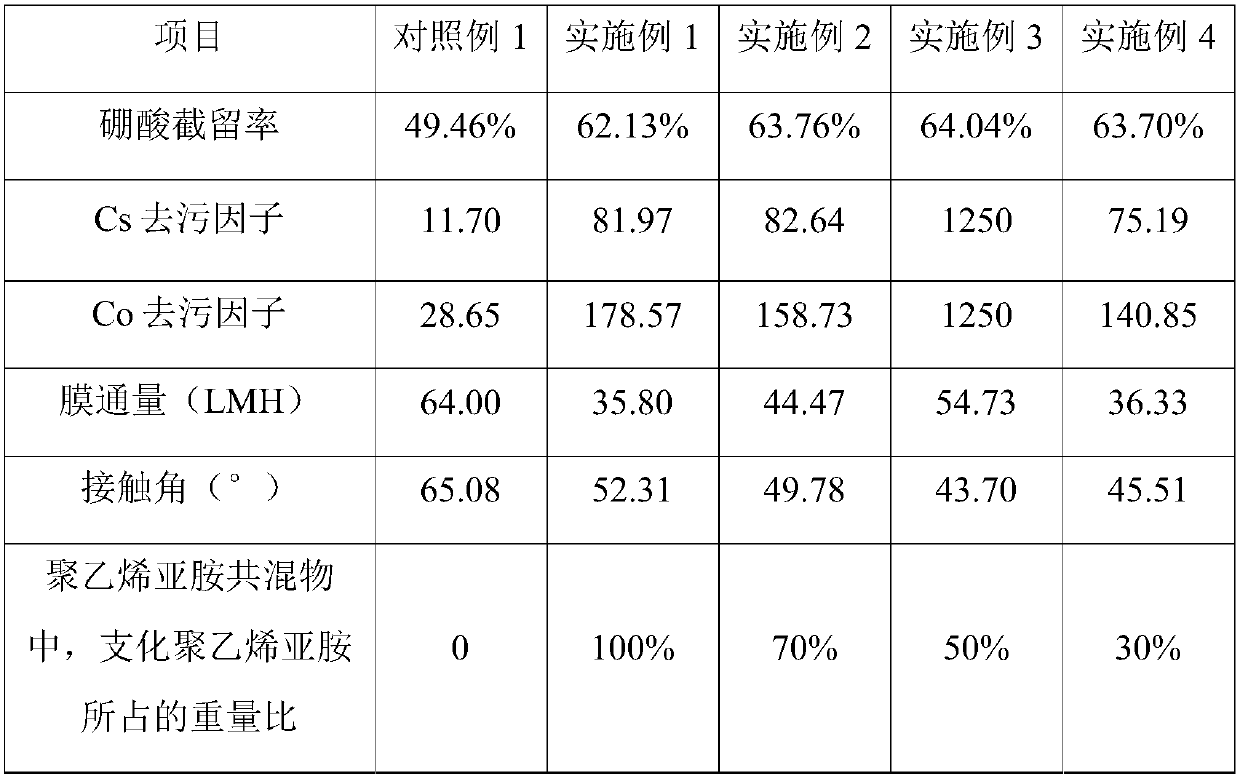

[0039] A method for intercepting boric acid in nuclear power plant liquid effluents, comprising the steps of: placing a reverse osmosis membrane (polyamide commercial reverse osmosis membrane LE) in 25% isopropanol solution to soak for 20 minutes, and then cleaning with deionized water 6 times, 30 minutes each time, store in deionized water at 4°C; then place the reverse osmosis membrane in the modification pool, cover with carbodiimide solution for 10 minutes, then add N-hydroxysuccinimide solution , poured out the waste liquid after covering for 50 minutes, and cleaned the reverse osmosis membrane with deionized water for 2 times; then the concentration of the reverse osmosis membrane was 5%, and the proportion of branched polyethyleneimine (branching degree was 60%) was 100%. The solution was covered for 12 hours, and light-shielding treatment was carried out during the process. Afterwards, the waste liquid was poured out, and the membrane was washed twice with deionized wat...

Embodiment 2

[0043] A method for intercepting boric acid in nuclear power plant liquid effluents, comprising the steps of: placing a reverse osmosis membrane (polyamide commercial reverse osmosis membrane LE) in 25% isopropanol solution to soak for 20 minutes, and then cleaning with deionized water 6 times, 30 minutes each time, store in deionized water at 4°C; then place the reverse osmosis membrane in the modification pool, cover with carbodiimide solution for 10 minutes, then add N-hydroxysuccinimide solution , poured out the waste liquid after covering for 50 minutes, and cleaned the reverse osmosis membrane 2 times with deionized water; then the concentration of the reverse osmosis membrane was 5%, and the proportion of branched polyethyleneimine (branching degree was 60%) was 70%. The solution was covered for 12 hours, and light-shielding treatment was carried out during the process. Afterwards, the waste liquid was poured out, and the membrane was washed twice with deionized water to...

Embodiment 3

[0047] A method for intercepting boric acid in nuclear power plant liquid effluents, comprising the steps of: placing a reverse osmosis membrane (polyamide commercial reverse osmosis membrane LE) in 25% isopropanol solution to soak for 20 minutes, and then cleaning with deionized water 6 times, 30 minutes each time, store in deionized water at 4°C; then place the reverse osmosis membrane in the modification pool, cover with carbodiimide solution for 10 minutes, then add N-hydroxysuccinimide solution , poured out the waste liquid after covering for 50 minutes, and cleaned the reverse osmosis membrane 2 times with deionized water; then the concentration of the reverse osmosis membrane was 5%, and the proportion of branched polyethyleneimine (branching degree was 60%) was 50%. The solution was covered for 12 hours, and light-shielding treatment was carried out during the process. Afterwards, the waste liquid was poured out, and the membrane was washed twice with deionized water to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com