Hydraulic vibration device

A technology of hydraulic vibration and vibration source, which is applied in the direction of fluid pressure actuators, electromechanical devices, fluid pressure actuator system components, etc., can solve the problems of high failure rate and inability to adjust, and achieve low failure rate, strong applicability, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described now in conjunction with accompanying drawing.

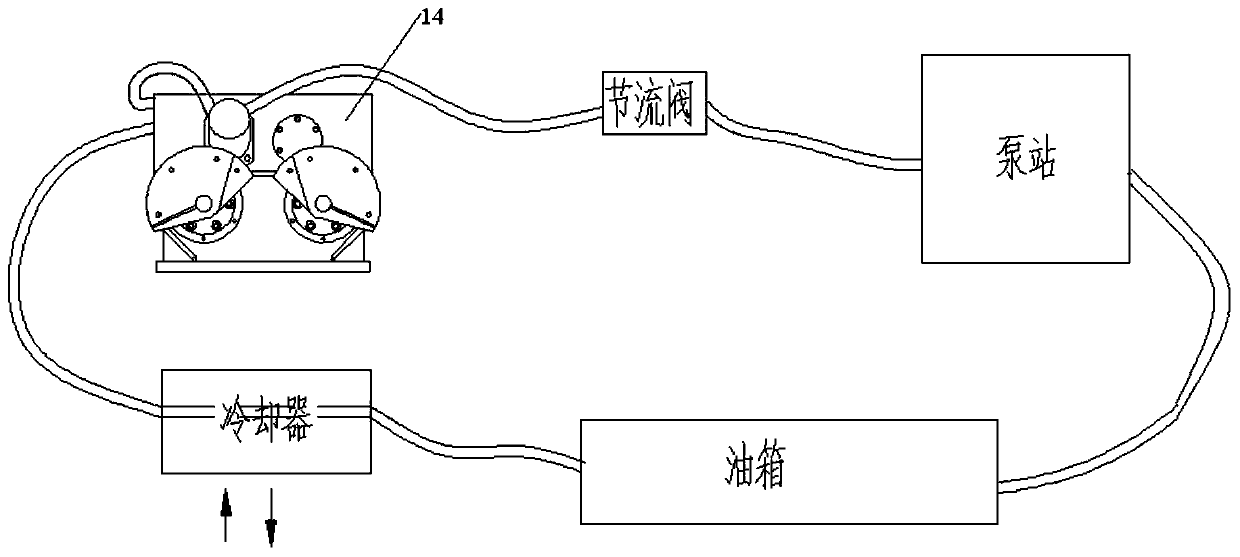

[0034] The present invention also provides a hydraulic vibrating device 14, which uses hydraulic drive technology to drive the eccentric block through a hydraulic motor to generate an exciting force, and at the same time, after hydraulic oil is introduced into the vibration source shell, it enters the cooling system through a hydraulic pipeline, and realizes While lubricating the internal transmission gear, it cools the vibration source gear mechanism. Through the adjustment of the hydraulic valve, the stepless speed change can be realized without stopping the machine, which greatly improves the safety and work efficiency of the equipment.

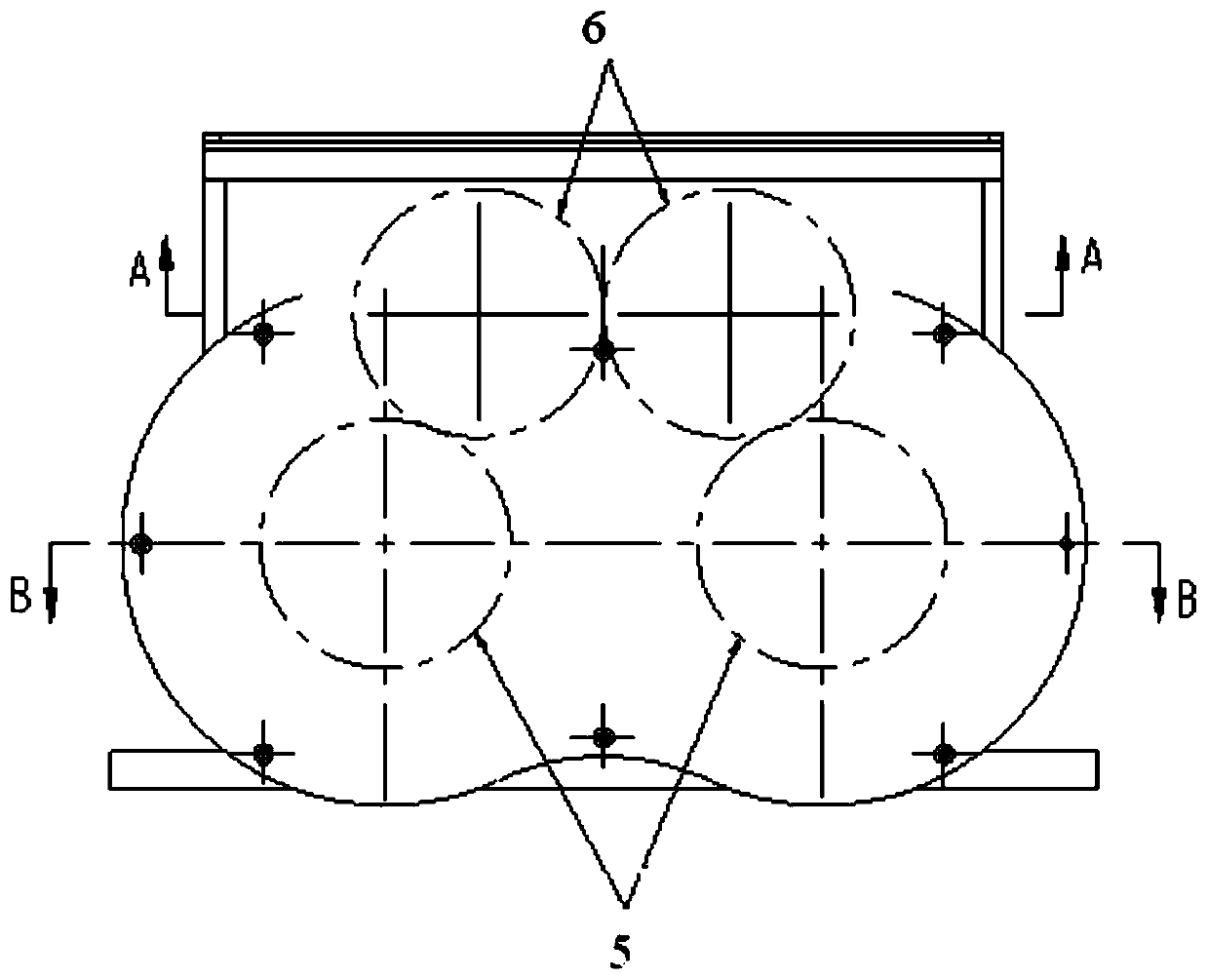

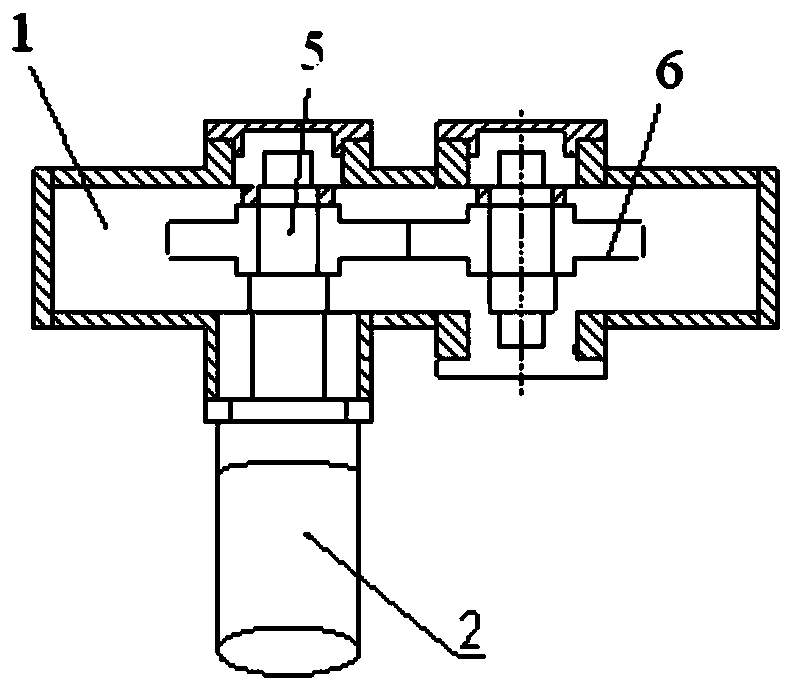

[0035] Such as figure 2 , 3 As shown in and 4, the hydraulic vibration device includes: a vibration source 1 and a power source 2, the power source 2 is used to generate power, and is transmitted to the polarization block of the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com