Automatic assembly for cutting off afforestation nursery stock branches

A technology for cutting off components and branches, applied in the field of greening, can solve problems such as high labor intensity, inconvenient operation, and tilting of knives and saws, and achieve the effect of reducing labor intensity and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

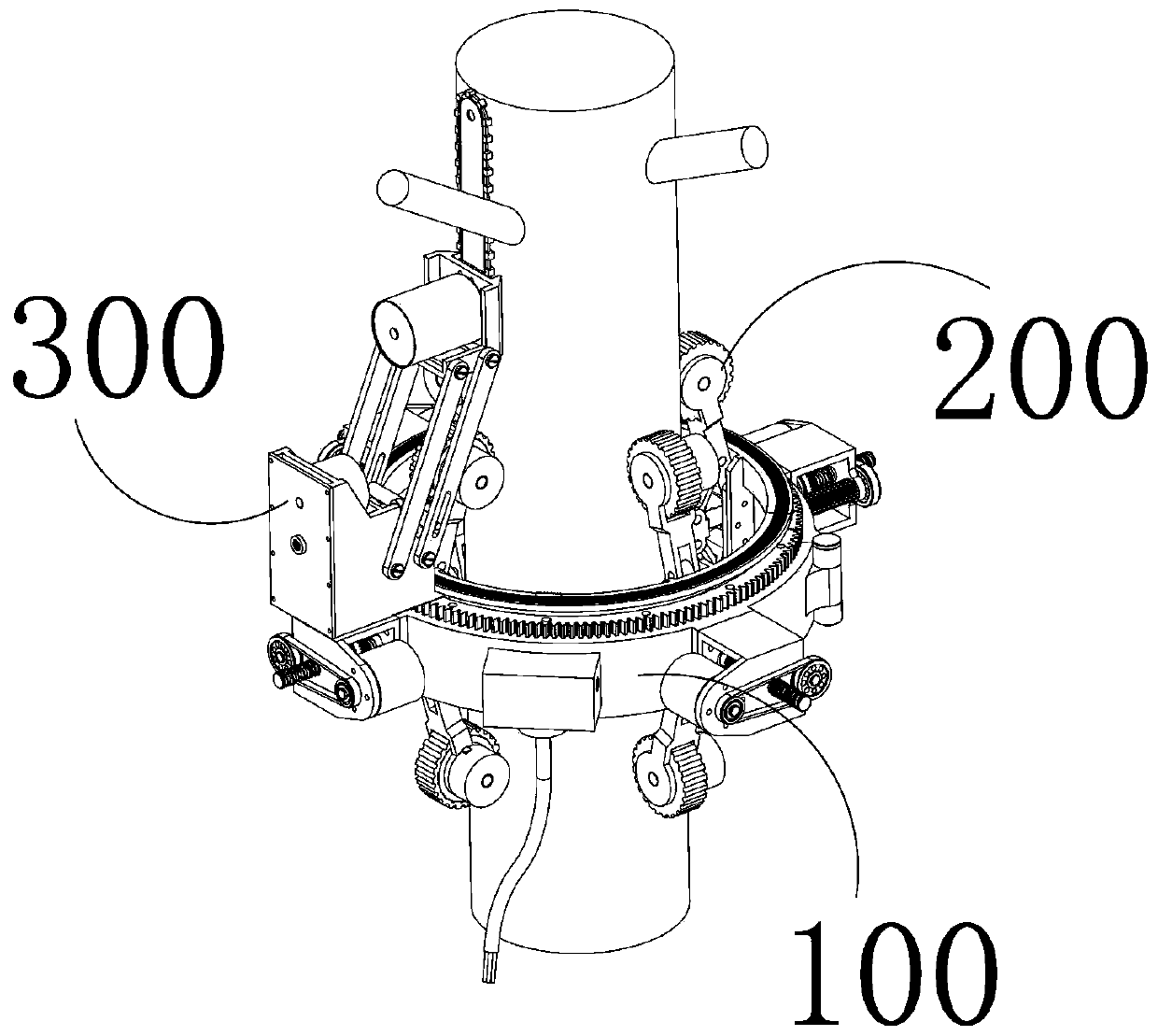

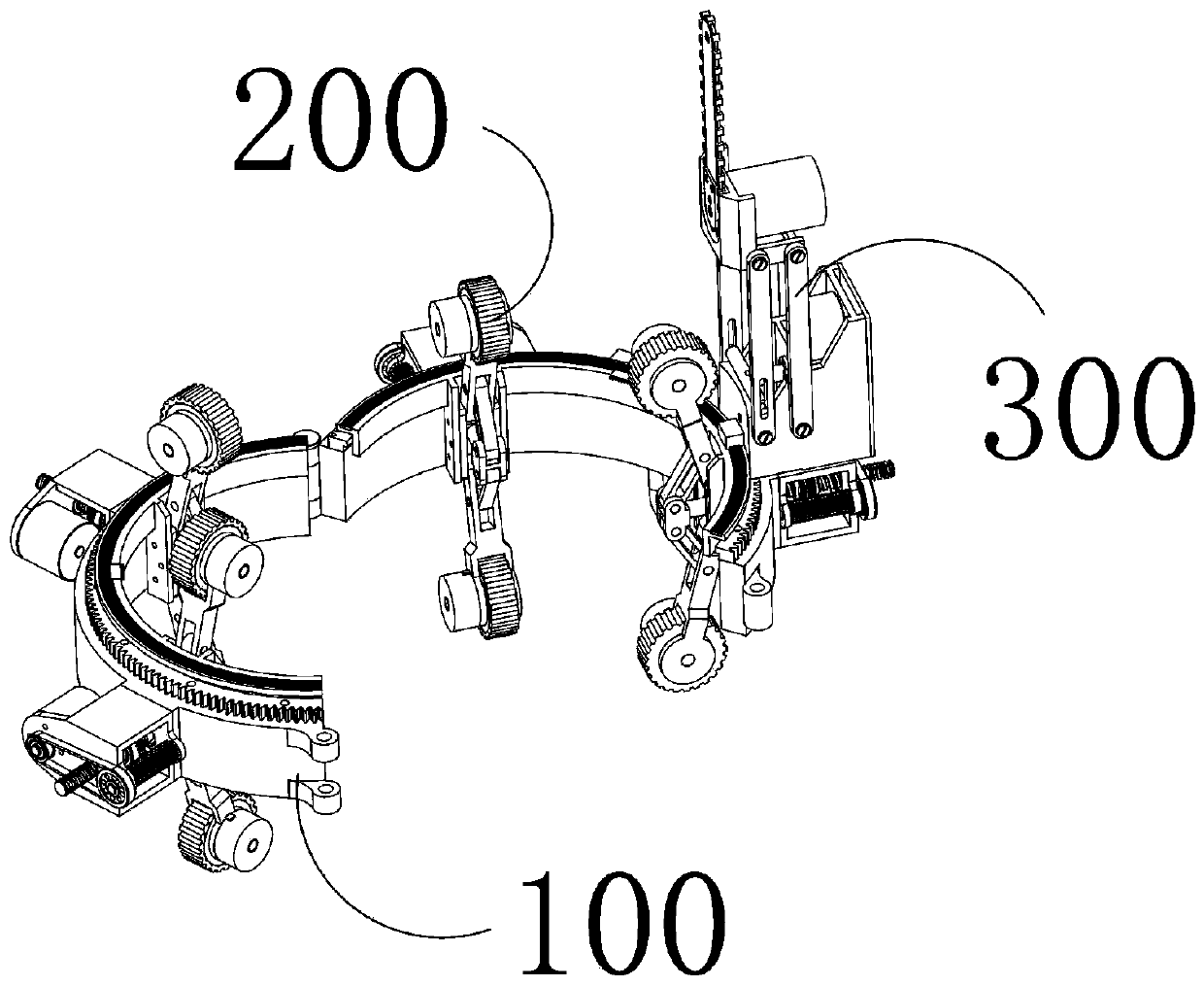

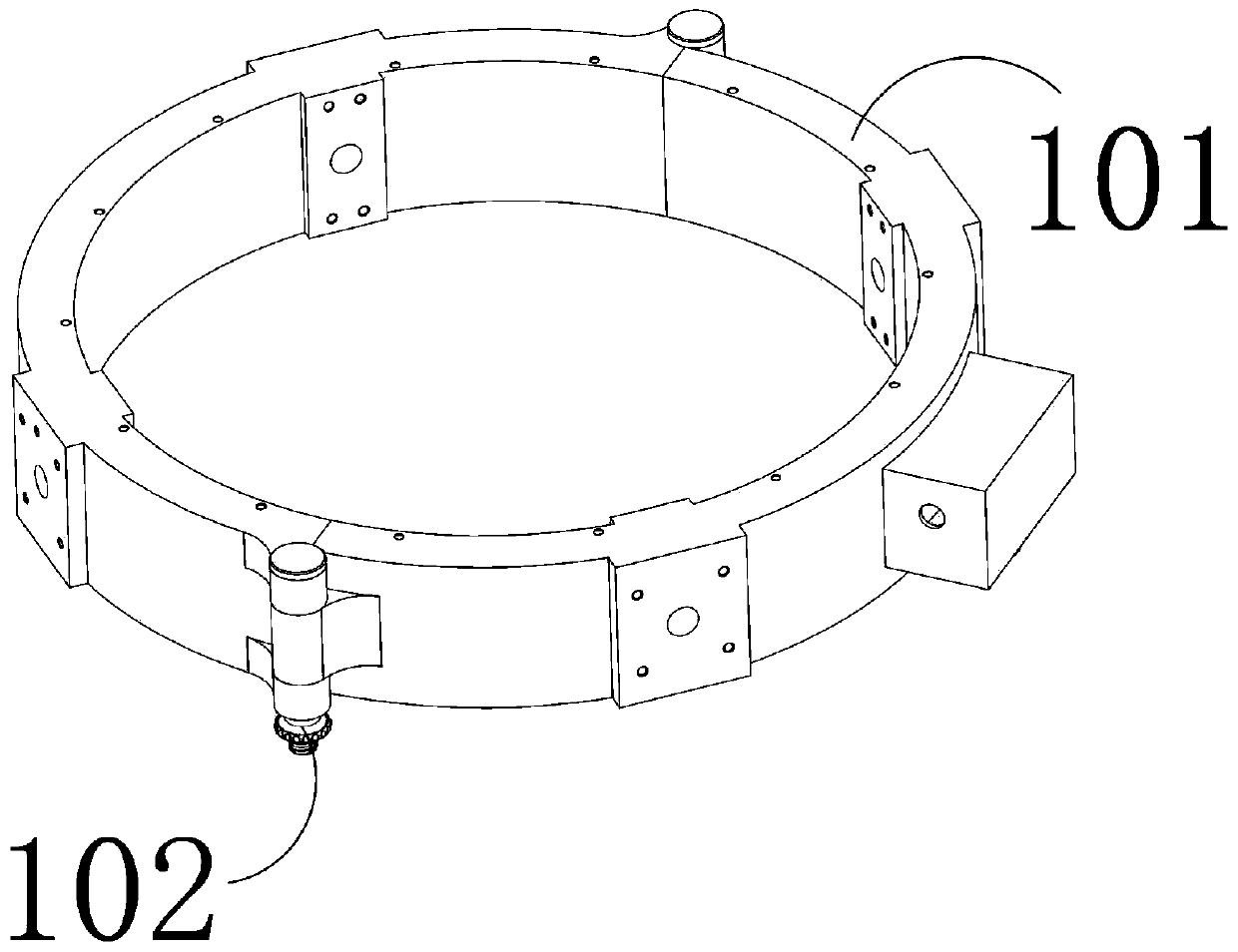

[0051] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0052] The advantage of the present invention for branch repair of trees to be pruned is that it only needs the staff to assist the staff to install the branch repair machine coaxially outside the trunk of the tree, and the subsequent tree climbing and branch cutting repair process only need the staff to operate The controller further controls the operation of the motor inside the lifting and climbing device and the branch repairing device to realize cutting and repairing of tree branches, which not only reduces the labor intensity of the staff, but also greatly improves the safety of the staff; at the same time, due to the Due to the existence of the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com