Partially frosted material and preparation method, partially frosted shell, electronic equipment

A frosted and partial technology, applied in the field of plastics, can solve the problems of insufficient appearance of finished products, difficulty in using performance, and unsuitable contact use, etc., to achieve the effect of improving machinability and use performance, low processing difficulty, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

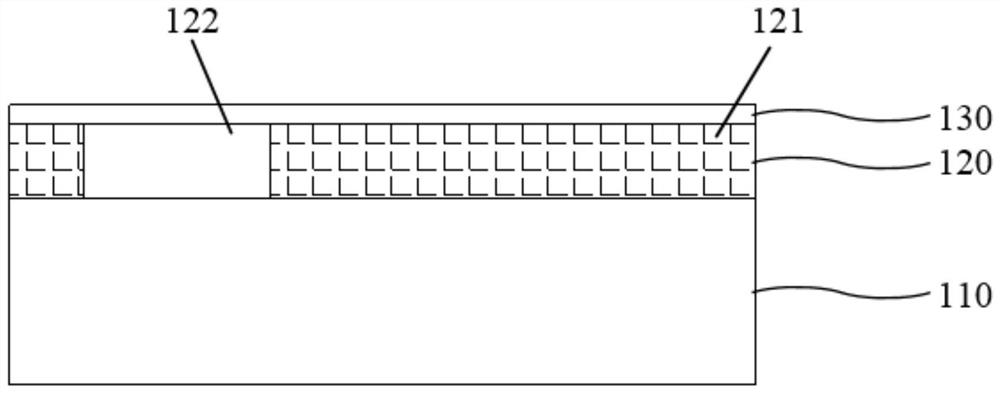

[0052] On the other hand, the present invention provides the preparation method of above-mentioned abrasive material, and this preparation method comprises the following steps:

[0053] Step S1, providing a substrate, the surface of the substrate is a plastic surface;

[0054]The plastic base material can be selected from commonly used portable electronic devices such as casing materials of mobile phones, or materials of protective cases thereof. Further, some hard plastic materials can be selected, for example, the plastic material is but not limited to at least one of polycarbonate plastic, polymethyl methacrylate and ABS plastic.

[0055] The plastic substrate can be pre-processed into the shape of the prepared device according to actual needs, or it can be a finished unprocessed plastic sheet. The plastic base material preprocessed into a device shape can be directly prepared through the preparation method provided by the invention to obtain the desired frosted plastic pr...

Embodiment 1

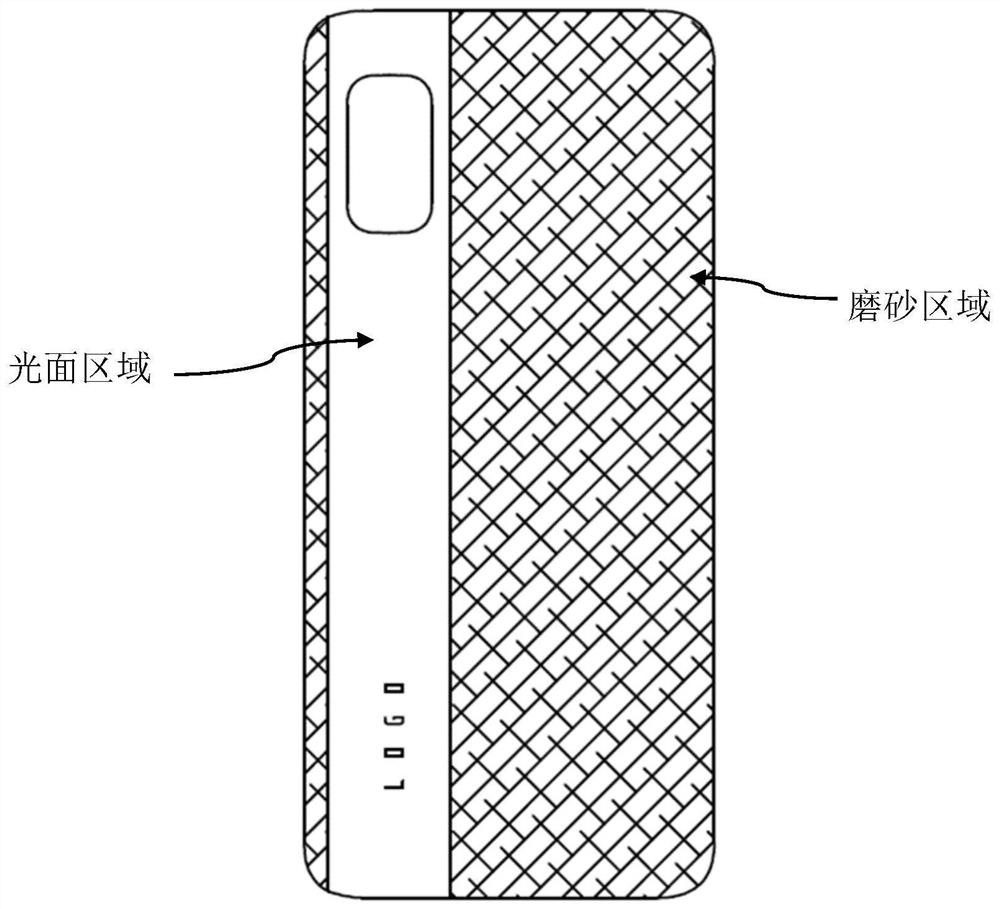

[0095] Plastic cover with frosted effect in local areas

[0096] (1) Hardening treatment: Prepare the pre-formed and cleaned plastic cover plate, pour a layer of high-hard fluorine-free light-curable coating on the surface of the plastic cover plate, and apply ultraviolet light for 5 minutes to make it completely cured, so that A hardened layer is formed on its surface.

[0097](2) Forming a partial protective layer: by screen printing, a layer of peelable glue is printed on the area of the plastic cover plate that forms a hardened layer on the surface as a smooth surface to form a partial protective layer. The thickness is 7 μm.

[0098] (3) Matte treatment: use the method of sandblasting to perform frosting treatment on the plastic cover plate with a partial protective layer on the surface, so that the surface has a frosted texture as a whole.

[0099] (4) Back protection: Use a scraper to peel off the peelable glue on the surface of the frosted plastic back cover to exp...

Embodiment 2

[0102] Plastic cover with frosted effect in local areas

[0103] (1) Hardening treatment: Prepare the preformed and cleaned plastic cover plate, spray a layer of high-hard light-curing paint on the surface of the plastic cover plate and apply ultraviolet light for 3 minutes to make it completely cured, so that the surface Form a hardened layer.

[0104] (2) Forming a partial protective layer: by screen printing, a layer of peelable glue is printed on the area of the plastic cover plate that forms a hardened layer on the surface as a smooth surface to form a partial protective layer. The thickness is 9 μm.

[0105] (3) Frosted treatment: use laser etching method to perform frosted treatment on the plastic cover plate with partial protective layer formed on the surface, so that the surface has a frosted texture as a whole.

[0106] (4) Back protection: Use a scraper to peel off the peelable glue on the surface of the frosted plastic back cover to expose the original plastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com