Vehicle, driving system thereof, and vehicle driving wheel

A vehicle drive and drive system technology, applied to vehicle components, motion deposition, power devices, etc., can solve problems such as insufficient installation space and excessive structure, and achieve convenient manufacturing and assembly, convenient layout and installation, large transmission ratio and Effect of output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

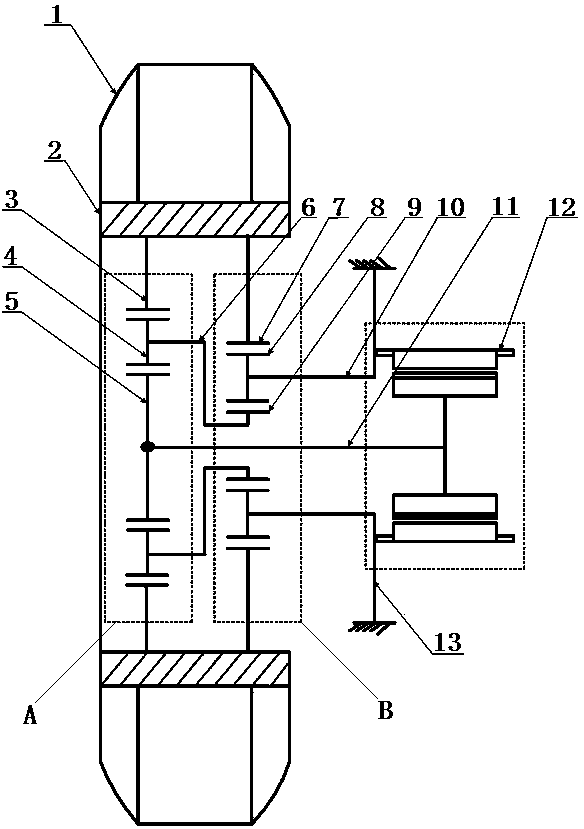

[0025] The partial structure schematic diagram of embodiment 1 of vehicle among the present invention is as figure 1 As shown, it includes a vehicle frame (not shown in the figure) and a drive system. The drive system includes a vehicle drive wheel and a drive motor 12 for driving the vehicle drive wheel to rotate. The vehicle drive wheel includes a wheel hub 2 and tires arranged on the outside of the wheel hub 2 1. The hub 2 is provided with a reduction mechanism, which is a double-planetary reduction mechanism, that is, the reduction mechanism includes two-stage planetary gear trains, which are respectively the primary planetary gear trains arranged side by side in the axial direction (that is, the first-stage planetary gear train A) and the two-stage planetary gear train B, the two-stage planetary gear train B is located axially inside the first-stage planetary gear train A, and the driving motor 12 is located axially inside the two-stage planetary gear train, "axially insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com