Sensor for monitoring water sediment content

A sediment content and sensor technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of single function, inconvenient measurement, and the sensor cannot realize data correction, etc., and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

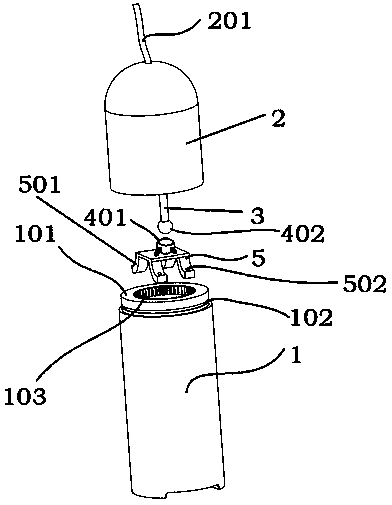

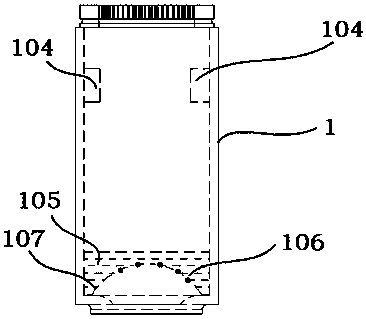

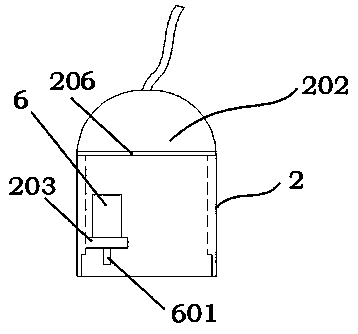

[0035] This embodiment proposes a sensor for monitoring the sediment content in water bodies, such as figure 1 As shown, including the first housing 1 and the second housing 2, the first housing 1 is in the shape of a column as a whole, so as to reduce the collision damage with the outside when rotating, and at the same time, the overall resistance is relatively small; A moving ring 101 is integrally formed on the opening side of the housing 1, which reduces assembly parts, has better sealing performance, is easy to process, and is light in weight; a circumferential groove 102 is provided on the outer wall of the moving ring 101 for assembling an O-ring The inner diameter of the opening side of the second housing 2 matches the outer diameter of the moving ring 101, so as to realize the dynamic sealing after the assembly of the first housing 1 and the second housing 2, and form a closed cavity. When the first housing 1 rotates at a low speed relative to the second housing 2 (fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com