Ultraviolet disinfection device based on optical waveguide, and terminal

An ultraviolet disinfection and optical waveguide technology, applied in disinfection, water supply equipment, sanitary equipment for toilets, etc., can solve the problems of ultraviolet attenuation, increase disinfection time, carcinogenicity, etc., and achieve the effect of less human injury, simple structure, and precise disinfection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

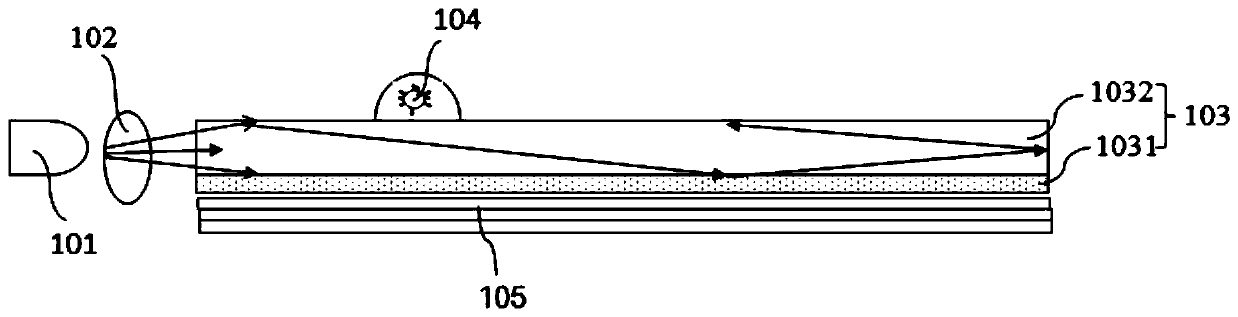

[0037] Embodiment 1 of the present invention provides a kind of ultraviolet disinfection device based on optical waveguide, such as Figure 5 As shown, the ultraviolet disinfection device based on optical waveguide includes a first ultraviolet light source, a first optical coupler 502 and a first optical waveguide optical film 503, and the first optical waveguide optical film 503 includes a first base layer 5031 and the first flat light guide film layer 5032 . The structure of the ultraviolet disinfection device in this embodiment is the same as that of the ultraviolet disinfection device mentioned in the preceding steps, the only difference is that the first optical coupler 502 in this embodiment is a grating coupler, and the first optical coupler 502 is a grating coupler. The coupler 502 is a periodic grating structure disposed on the first flat light guide film layer 5032 . After the incident light enters the first optical waveguide light-guiding film 503 through the first...

Embodiment 2

[0039] Embodiment 2 of the present invention provides a kind of ultraviolet disinfection device based on optical waveguide, such as Image 6 As shown, the ultraviolet disinfection device based on optical waveguide includes a second ultraviolet light source, a second optical coupler 602 and a second optical waveguide light guiding film 603, and the second optical waveguide light guiding film 603 includes a second base layer 6031 And the second flat light guide film layer 6032. The structure of the ultraviolet disinfection device described in this embodiment is the same as the structure of the ultraviolet disinfection device mentioned in the preceding steps, the only difference is that the second optical coupler 602 described in this embodiment is a prism coupler, when incident to the second When the incident angle of the ultraviolet light at the bottom of the optical coupler 602 is greater than the critical angle of total reflection, an evanescent field will be generated in the...

Embodiment 3

[0041] Embodiment 3 of the present invention provides a kind of ultraviolet disinfection device based on optical waveguide, such as Figure 7 As shown, the ultraviolet disinfection device based on optical waveguide includes a third ultraviolet light source, a third optical coupler 702 and a third optical waveguide light guiding film 703 ', and the third optical waveguide light guiding film 703 includes a third base layer 7031 and the third flat light guide film layer 7032. The structure of the ultraviolet disinfection device described in this embodiment is the same as that of the ultraviolet disinfection device mentioned in the preceding steps, the only difference is that the third optical coupler 702 described in this embodiment is a lens coupler, and the third optical coupler 702 is used to couple The device 702 focuses the ultraviolet light provided by the ultraviolet light source directly on the end surface of the third flat light-guiding film layer 7032, and the ultraviol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com