Metal hose connector shielded welding device

A metal hose and shielded welding technology, applied in metal processing equipment, welding equipment, welding accessories, etc., can solve problems such as inability to solve reliable in-situ welding, and achieve the effect of avoiding poor positioning accuracy and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

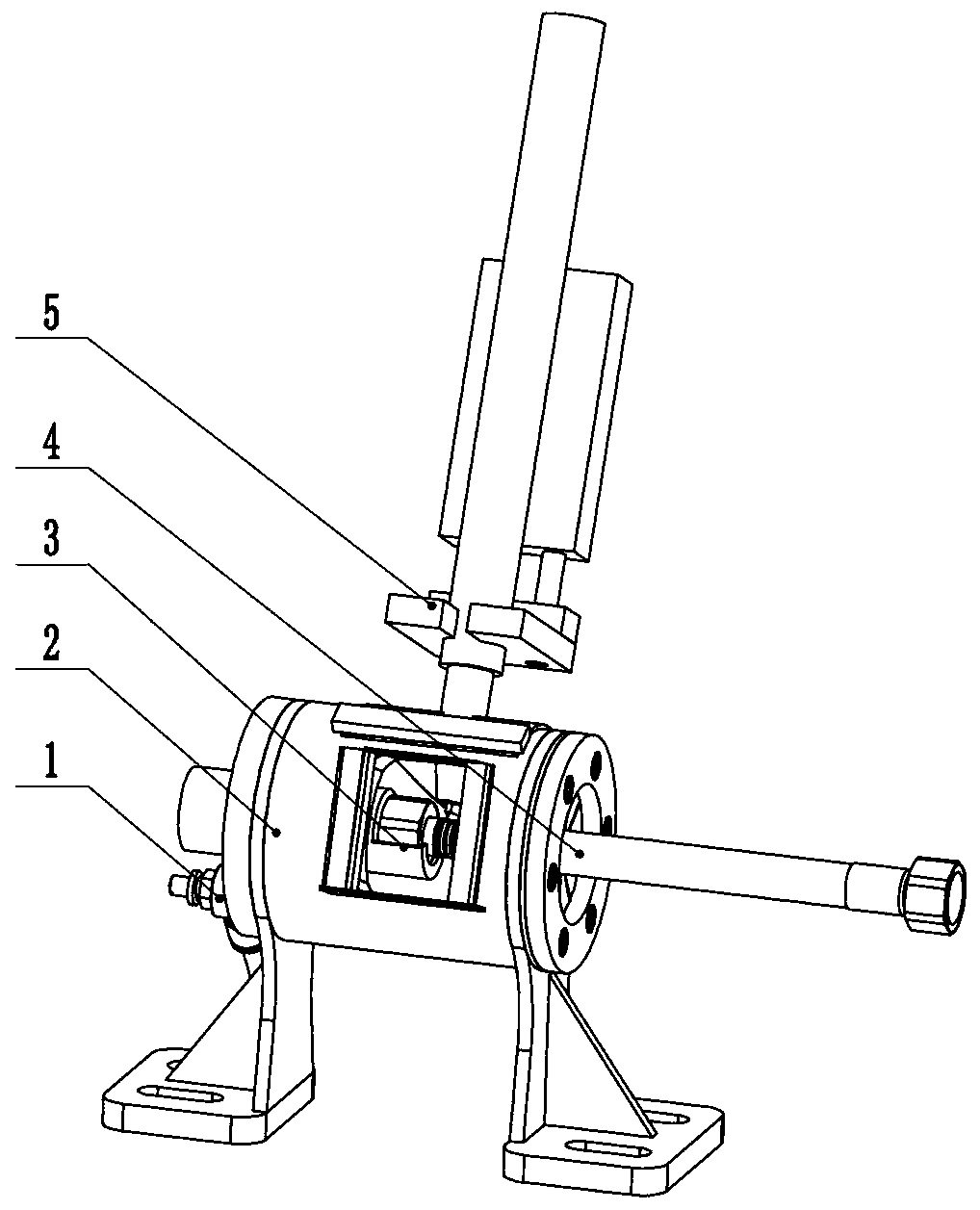

[0034] This embodiment is a protective welding device for metal hose joints used in cookers, and its basic structure is as follows: figure 1 As shown, it includes a ventilation interface 1, a closed cavity unit 2, a joint assembly positioning unit 3, a welding torch telescopic positioning unit 5, and a metal bellows unit 4 is placed in the joint assembly positioning unit 3 for welding positioning.

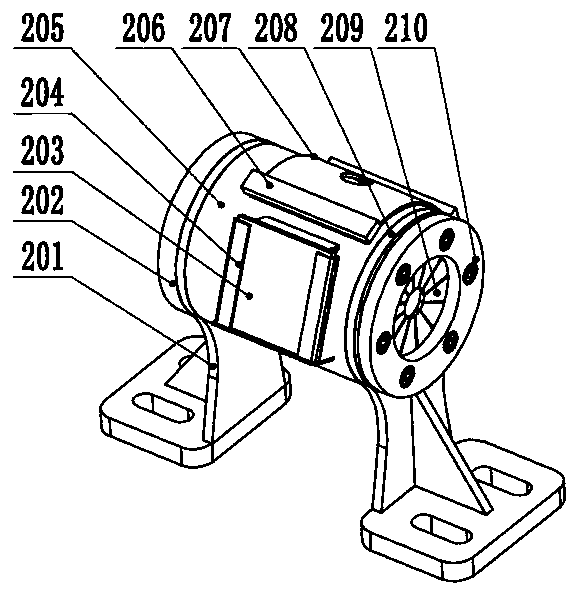

[0035] combine figure 2 It can be seen that the cylindrical hollow airtight chamber 205 as the main body of the airtight chamber unit 2 is supported on the vertical brackets 201 at its two ends, the front side has a welding observation port 204 for inserting the arc filter eyepiece 203, and the upper part is supported by a powerful magnetic block 206 The welding torch gasket 207 is fixed, and the middle part of the welding torch gasket 207 has a welding torch insertion hole. The two ends of the airtight chamber 205 are respectively equipped with a positioning end cap 202 and an ...

Embodiment 2

[0043] The basic structure of the shielded welding device for metal hose joints used in cooktops in this embodiment is the same as that of the embodiment, except that the metal hoses to be welded are such as Figure 10 As shown, it is a metal bellows with a socket threaded connection structure, which includes a socket threaded joint assembly 405, a bellows 403, a buckle ring 402, and a PVC coating 404. The socket thread assembly 405 is composed of a socket thread 4052 and a welded joint 4051. The corrugated pipe 403 is covered with a layer of PVC coating 404 and 2-3 corrugations are reserved at both ends. Before the two ends are welded, the crimping ring 402 is inserted. For this reason, its joint assembly positioning unit 3 such as Figure 11 and Figure 12 As shown, it includes a guide core rod 303, a lock nut 301, and a socket-type positioning slider 304, so the slider body of the positioning slider 304 is slightly different from that of the first embodiment.

[0044] Pra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com