Wood sawing device for forestry

A technology for sawing wood and equipment, which is applied in the direction of sawing equipment, circular saws, sawing components, etc., and can solve problems such as burrs on the edge of the saw surface, cracking on the surface of Mandshurica mandshurica, reducing the quality of Mandshurica mandshurica sawn wood, etc., to achieve reduction cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

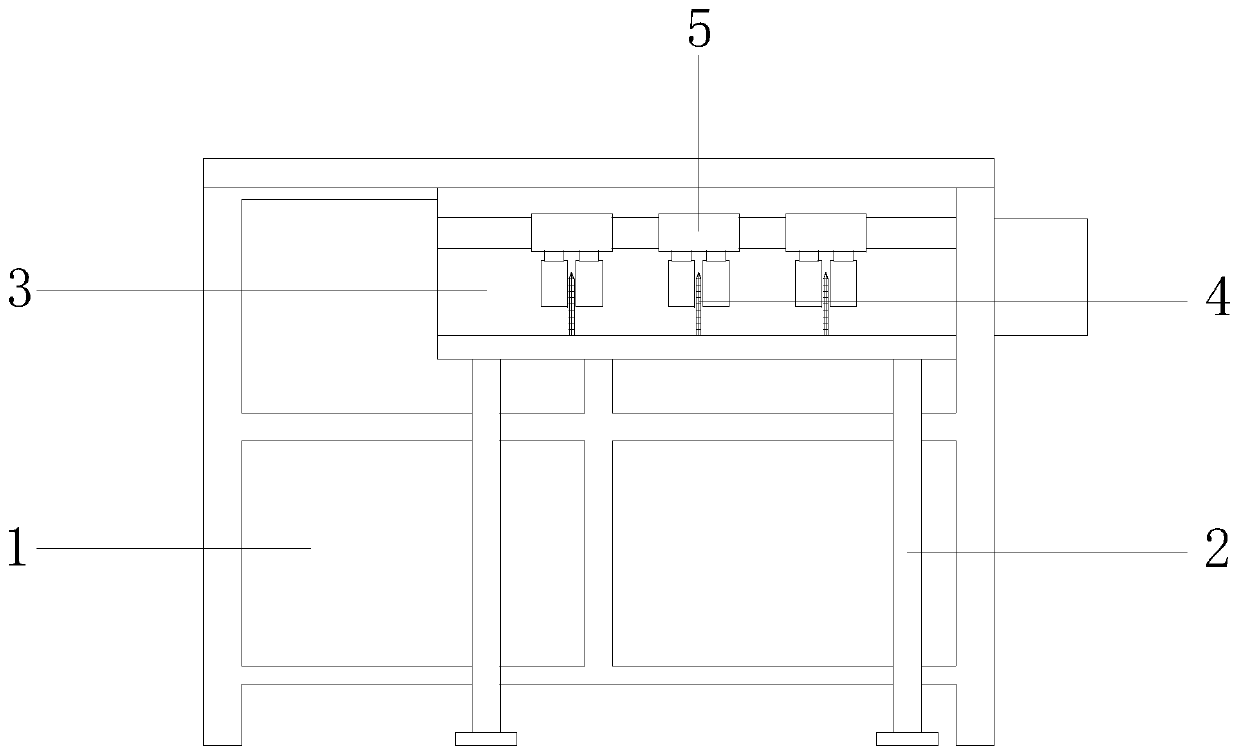

[0022] as attached figure 1 to attach Figure 5 Shown:

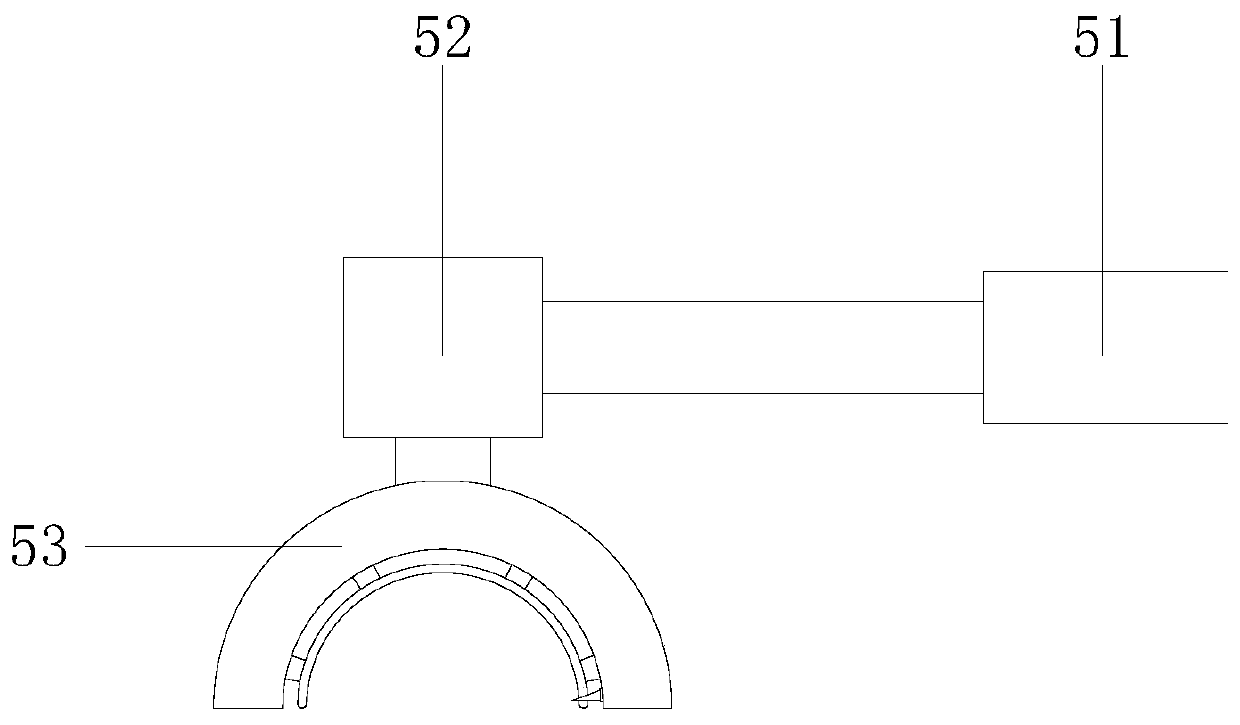

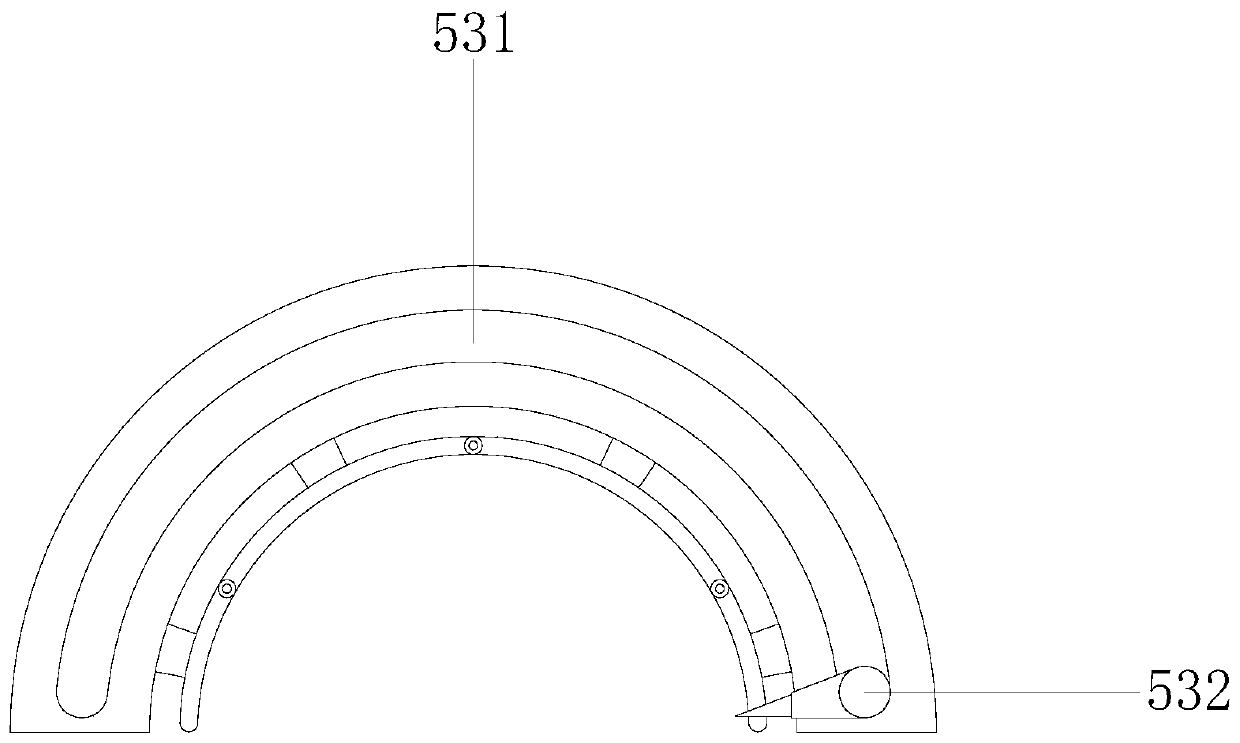

[0023] The present invention is a kind of sawing equipment for forestry, its structure includes a sawing table 1, a placement frame 2, a window 3, a saw blade 4, and a propulsion mechanism 5, and the right side of the front end of the sawing table 1 is fixedly installed with a placement frame 2 , the placement frame 2 is located at the front end of the window 3, the window 3 is embedded in the right side of the front end of the sawing table 1, the saw blade 4 is installed inside the sawing table 1, and the propulsion mechanism 5 is installed inside the sawing table 1 , and the propulsion mechanism 5 is located above the saw blade 4, the propulsion mechanism 5 includes a telescopic rod 51, a lifting rod 52, and an anti-warping mechanism 53, and the end of the telescopic rod 51 is fixedly installed inside the saw table 1, and the telescopic rod 51 The output end is fixed to the lifting rod 52, and the lower end of the li...

Embodiment 2

[0030] as attached Image 6 to attach Figure 7 Shown:

[0031] Wherein, the sliding mechanism 532 includes a sliding rail 32a, an electromagnetic block 32b, a sliding shaft 32c, a splinter removing plate 32d, and a spring 32e. Electromagnetic block 32b, described slide shaft 32c adopts clearance fit to be installed in slide rail 32a right-hand inside, described slide shaft 32c is fixed with the right end of thorn removal plate 32d, described slide rail 32a inside is equipped with spring 32e, and spring 32e right-hand end and The sliding shaft 32c is fixed, the electromagnetic block 32b is made of permanent magnet material, has electromagnetic properties, and the sliding shaft 32c is made of iron material, and the slide rail 32a is in an arc structure, which is beneficial to the electromagnetic block 32b to absorb the sliding shaft 32c, so that The sliding shaft 32c performs an arc-shaped trajectory operation.

[0032] Wherein, the thorn removal plate 32d is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com