Material distributing mechanism of material conveying system

A technology of conveying system and material distribution mechanism, which is applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., and can solve problems such as the failure to realize the material distribution function normally, the loss of adjustment function of the adjustment screw, and the position deviation of the material guide. , to achieve high internal space utilization, strong reliability and practicability, and avoid collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

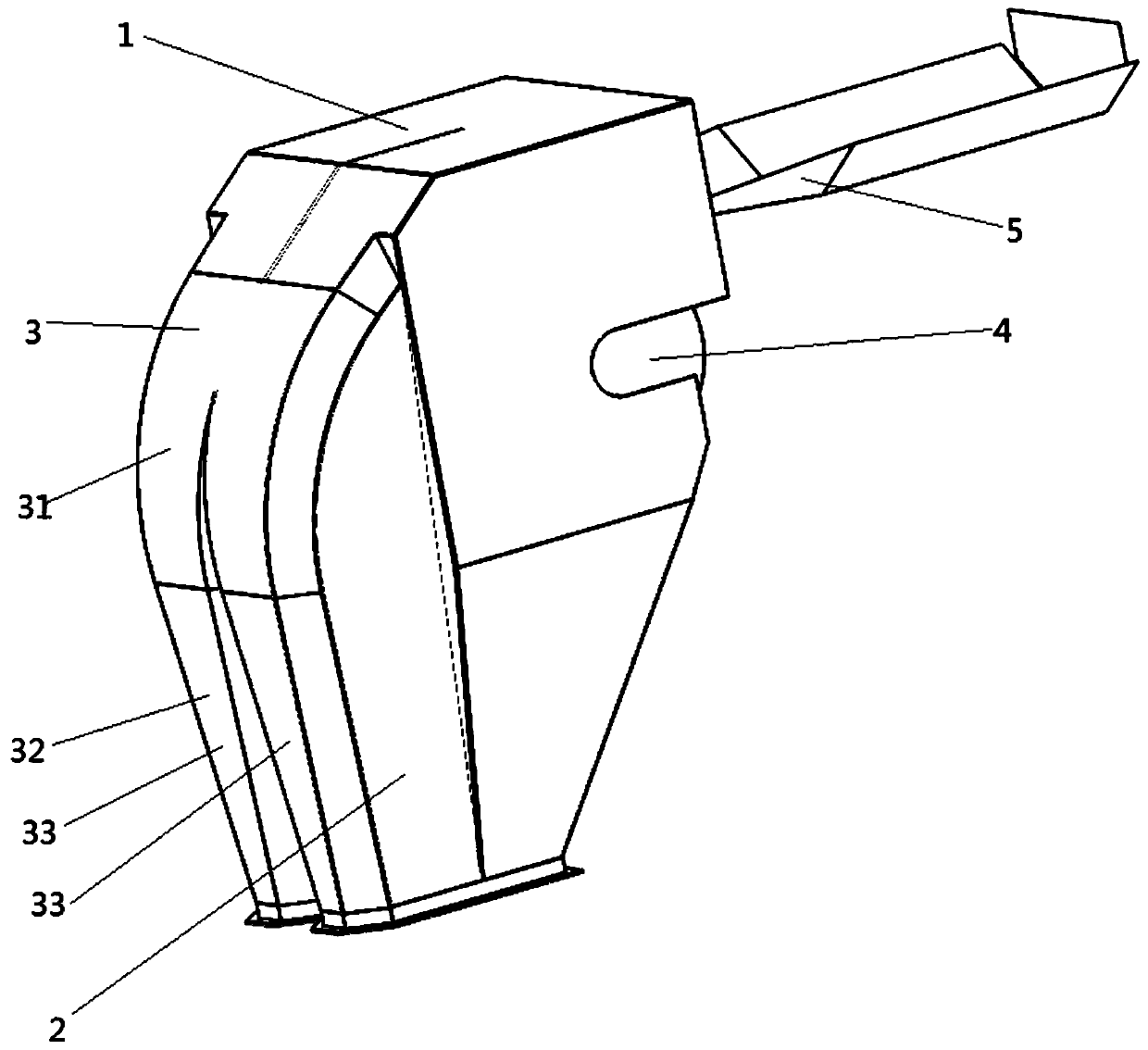

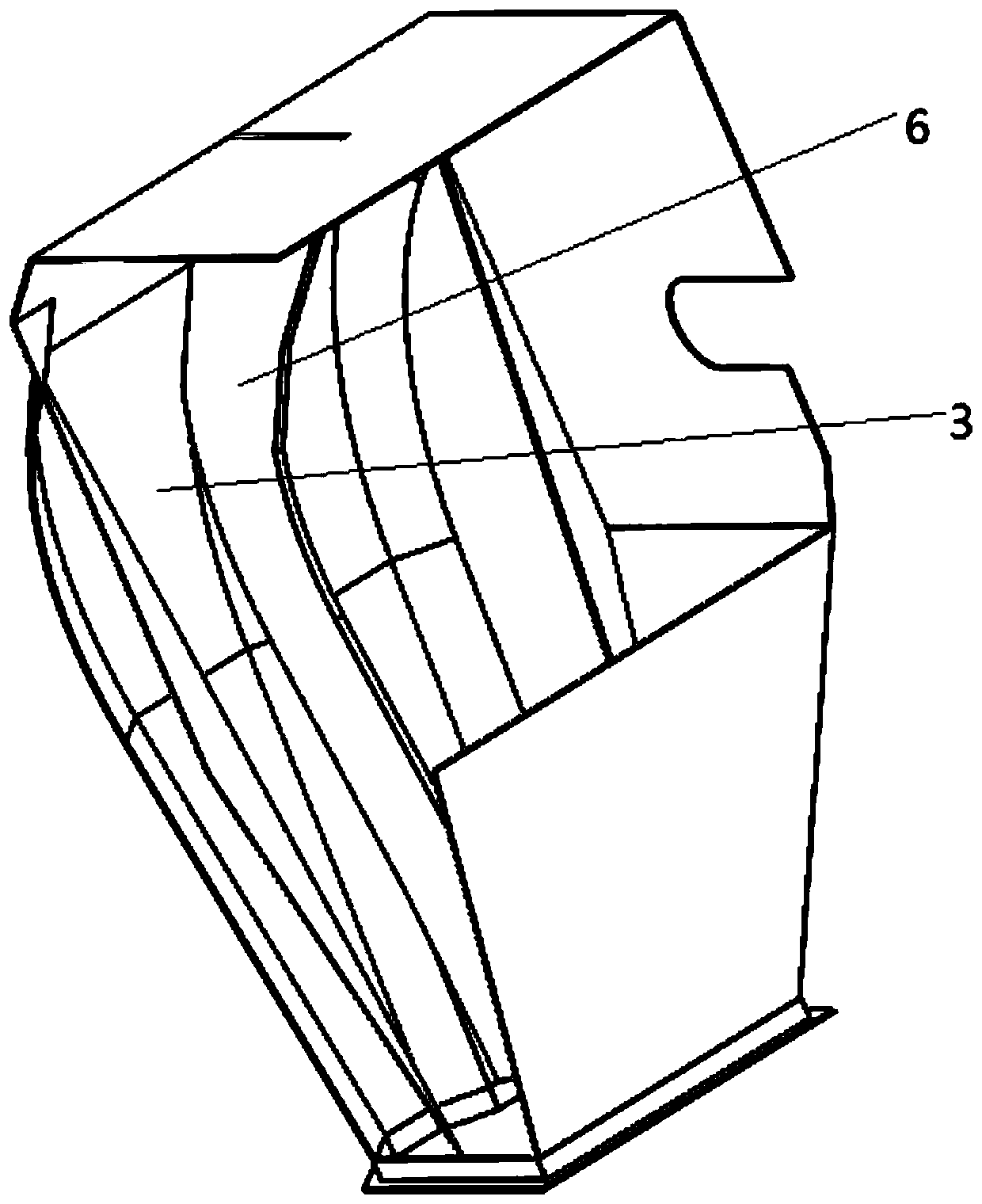

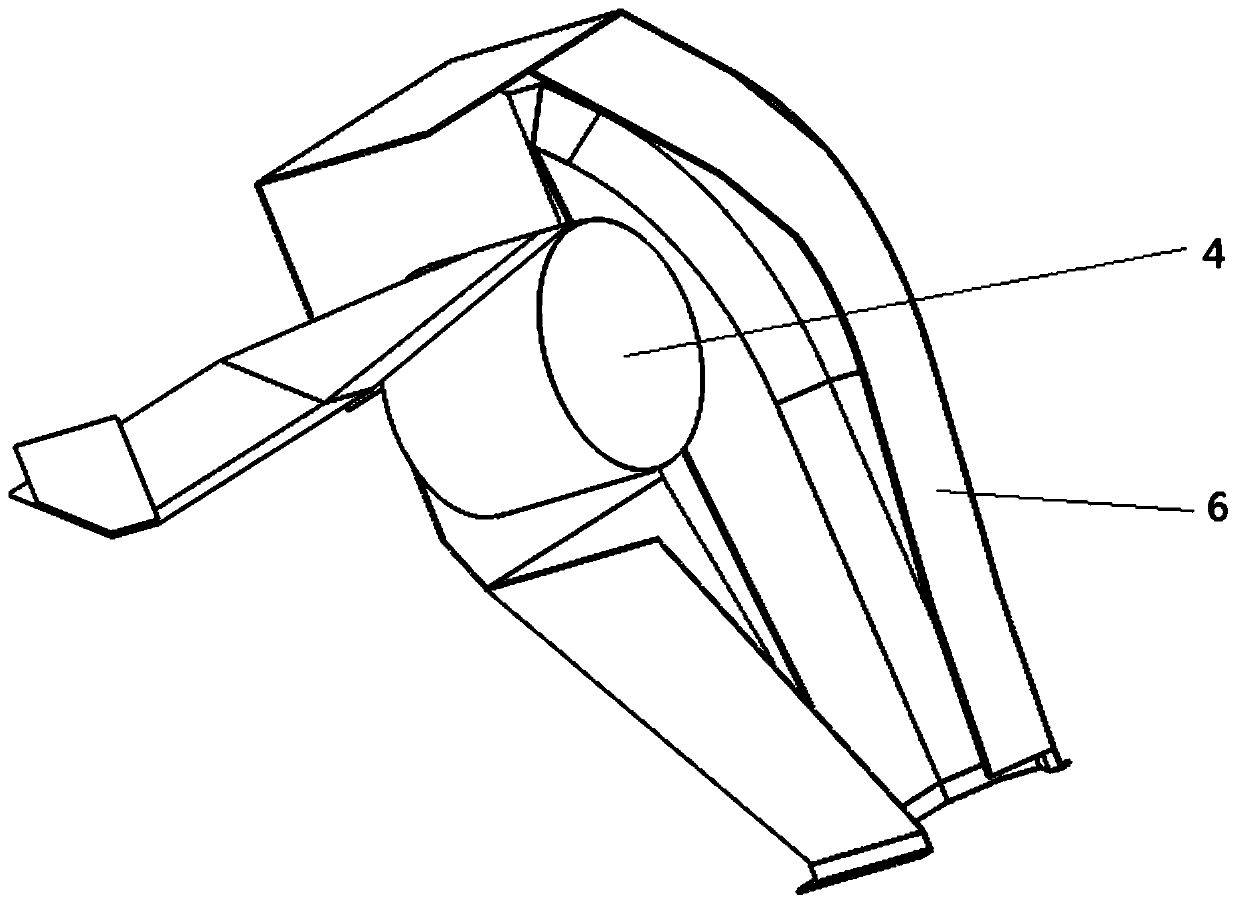

[0040] This embodiment provides a specific implementation of the material distribution mechanism of the material delivery system, such as Figure 1 to Figure 3 As shown, the material distributing mechanism includes a housing and a partition plate 6 .

[0041]One side wall of the housing is a material guide structure 3, which is used to guide the material to flow along a preset direction; the partition plate 6 is arranged on the material guide structure 3 and is located in the housing, and the partition plate 6 is provided with At least one for dividing material into strands. Specifically, the partition plate is vertically arranged on the material guide structure 3. Since one side wall of the housing is the material guide structure 3, the overall strength is relatively high, and the position of the material guide structure 3 will not change after being impacted by the material. , and then the position of the partition plate 6 arranged on the material guide structure 3 will not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com