Modular tool of steel plate for sealing water and construction method thereof

A water-stop steel plate and chemical technology, applied in water conservancy projects, artificial islands, protection devices, etc., can solve the problems of damage to the integrity of the water-stop steel plate, stress concentration at the perforated part, and cracks, so as to achieve a firm and reliable support structure and avoid water leakage , to ensure the effect of waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

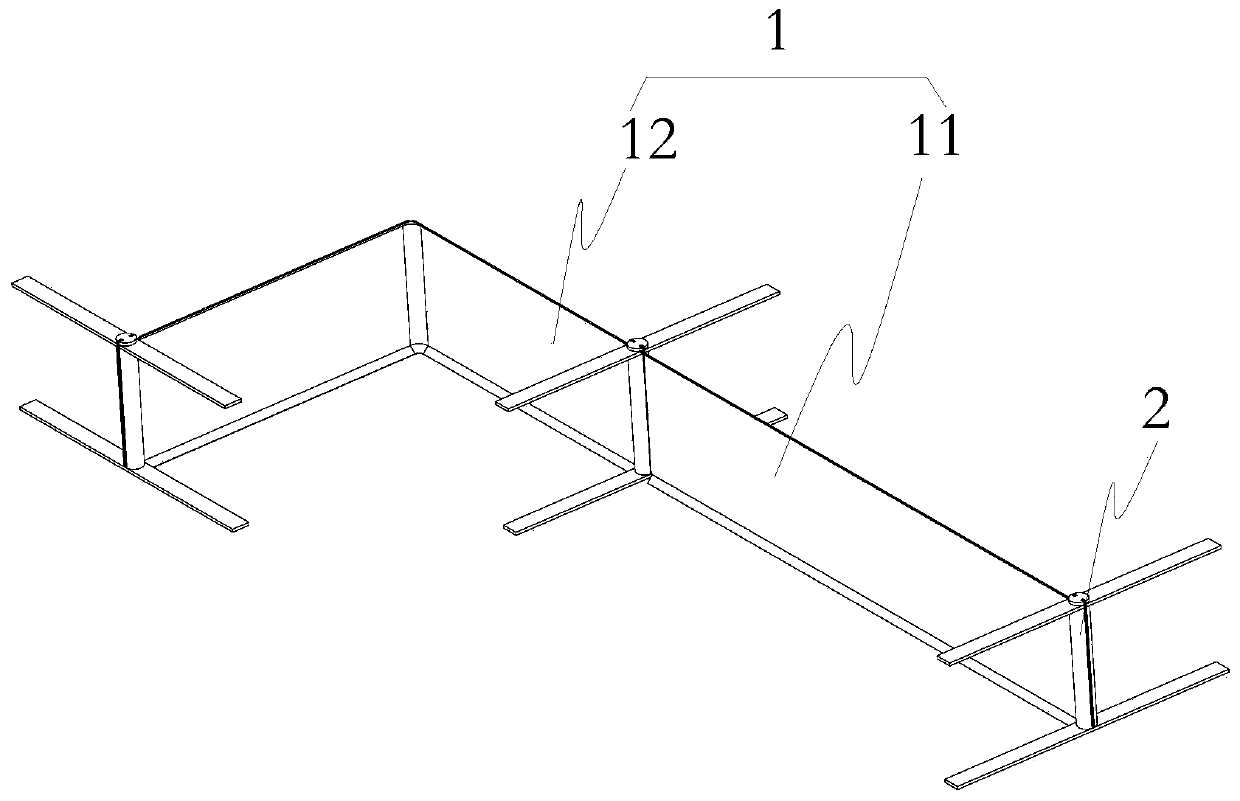

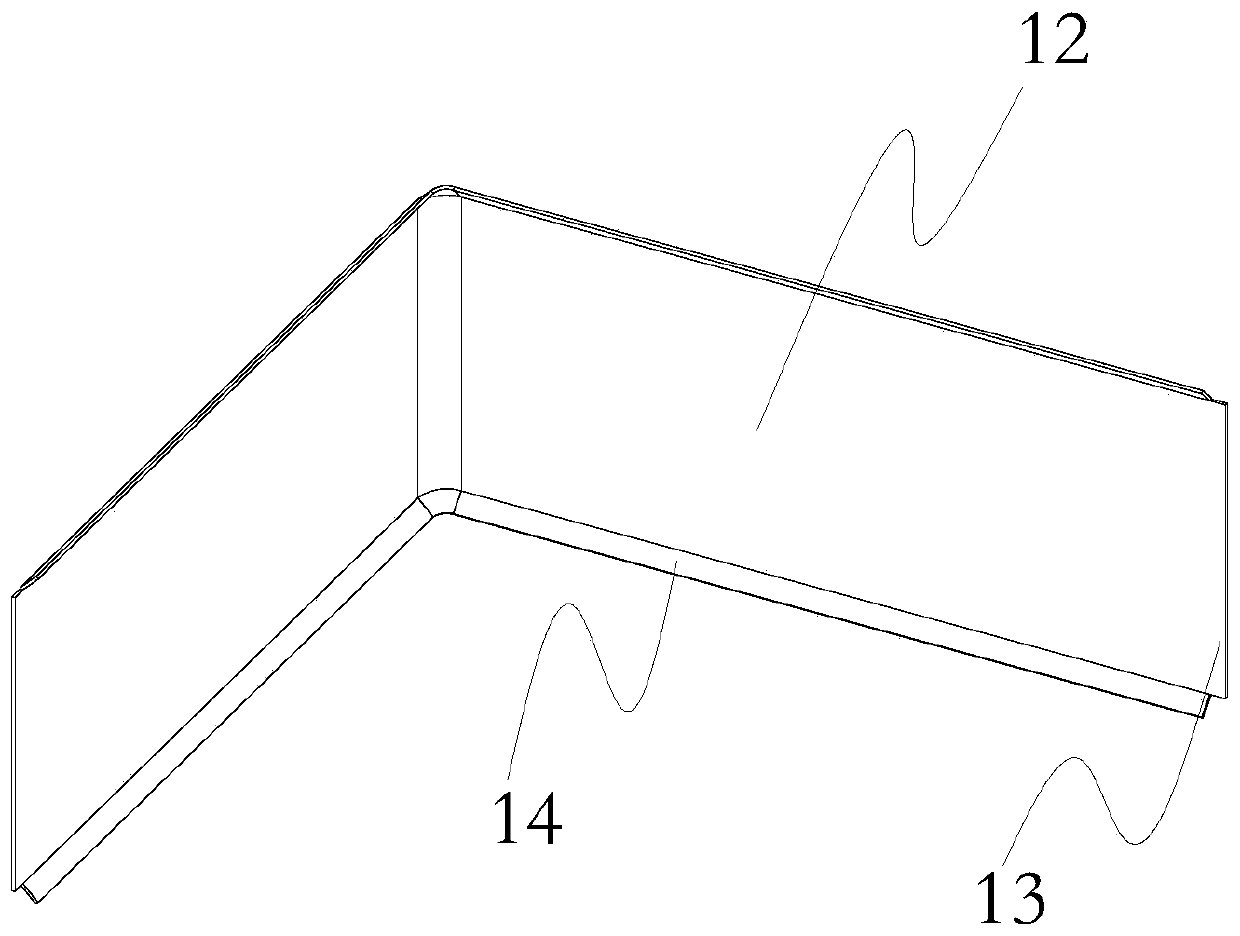

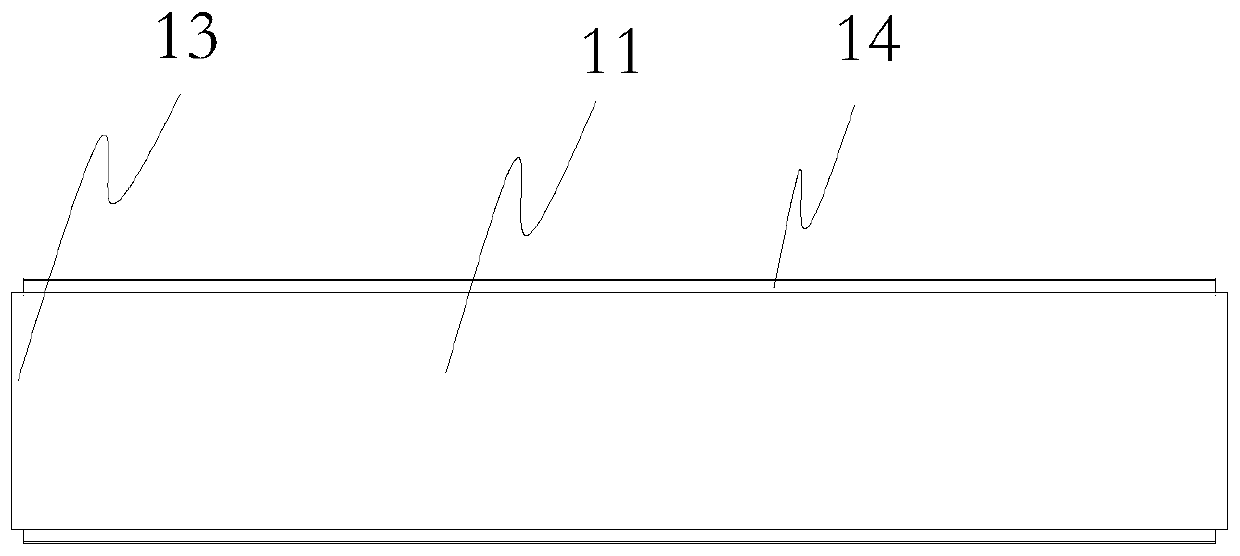

[0027] refer to figure 1 , a modular chemical installation of water-stop steel plates, comprising a prefabricated water-stop steel plate 1 and a prefabricated support member 2, mounting plates 13 are formed at both left and right ends of the prefabricated water-stop steel plate 1, and the prefabricated water-stop steel plate 1 includes vertical Straight steel plate 11 and bent steel plate 12, the middle part of the bent steel plate 12 is formed with a bent part; the prefabricated support member 2 includes a vertical stop bar 21 and a horizontal fixed bar 23, and the stop bar 21 and The fixed rod 23 is fixedly connected, and the prefabricated support member 2 is bound and fixed on the steel frame through the fixed rod 23; The limit groove 22 embedded in the plate 13, the installation plate 13 of the prefabricated water-stop steel plate 1 can be embedded and fixed in the limit groove 22, and the space between the limit groove 22 and the installation plate 13 is filled with Seal...

Embodiment 2

[0039] In this embodiment, after the mounting plate 13 of the prefabricated water-stop steel plate 1 is embedded and installed in the limiting groove 22, the gap between the limiting groove 22 and the mounting plate 13 is welded to form a the sealing material.

Embodiment 3

[0041] In this embodiment, after the installation plate 13 of the prefabricated water-stop steel plate 1 is embedded and installed in the limiting groove 22, a waterproof coating is applied between the limiting groove 22 and the installation plate 13. Glue forms the sealing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap