Oil separator

A technology for separators and petroleum, applied in the direction of isolation devices, production fluids, wellbore/well components, etc., can solve the problems of weakened flow of oil inlet pipes, reduced gas separation effect, increased viscosity of heavy oil, etc., to reduce the precipitation of wax crystallization, increasing temperature, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] as attached figure 1 to attach Figure 5 Shown:

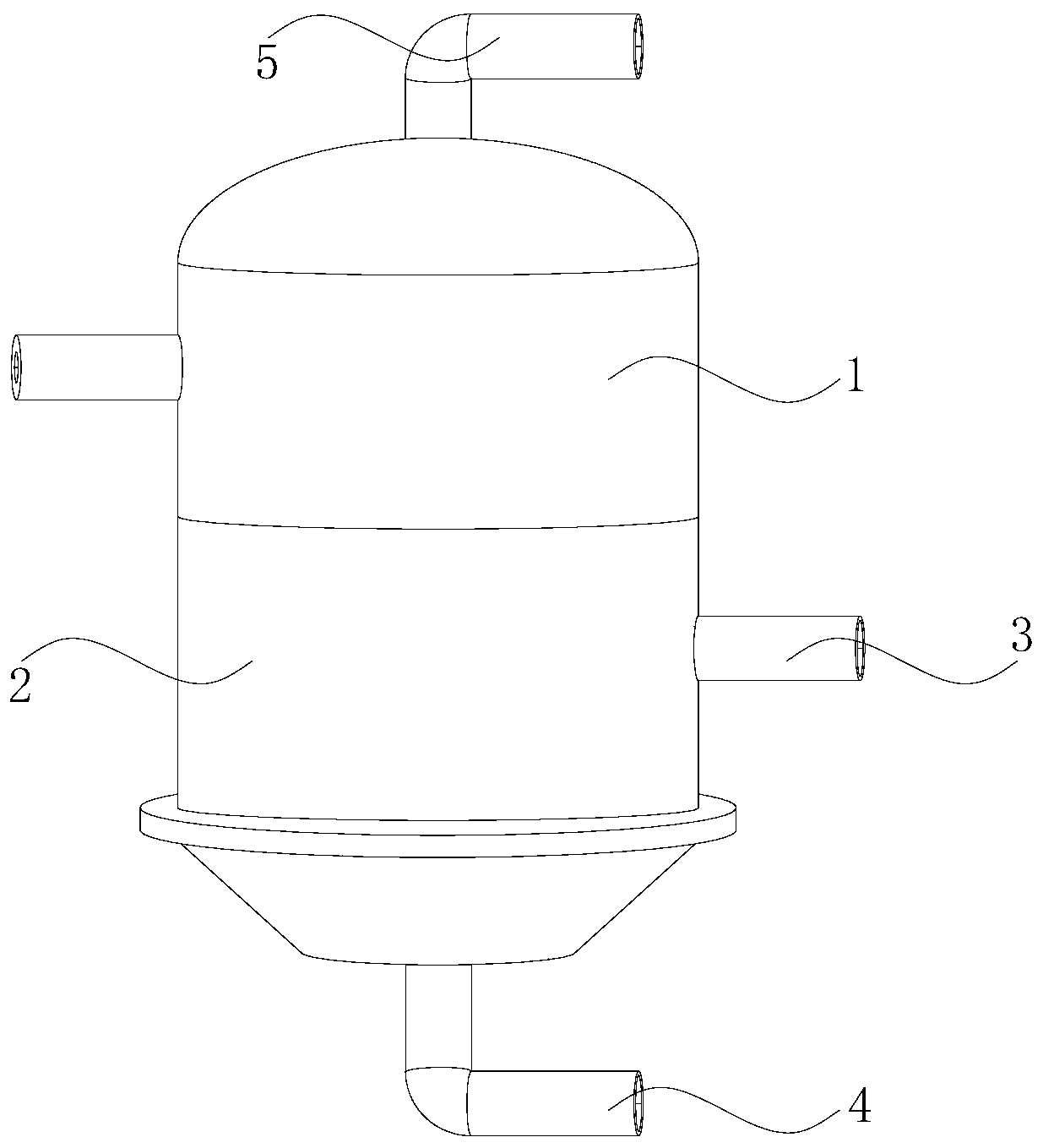

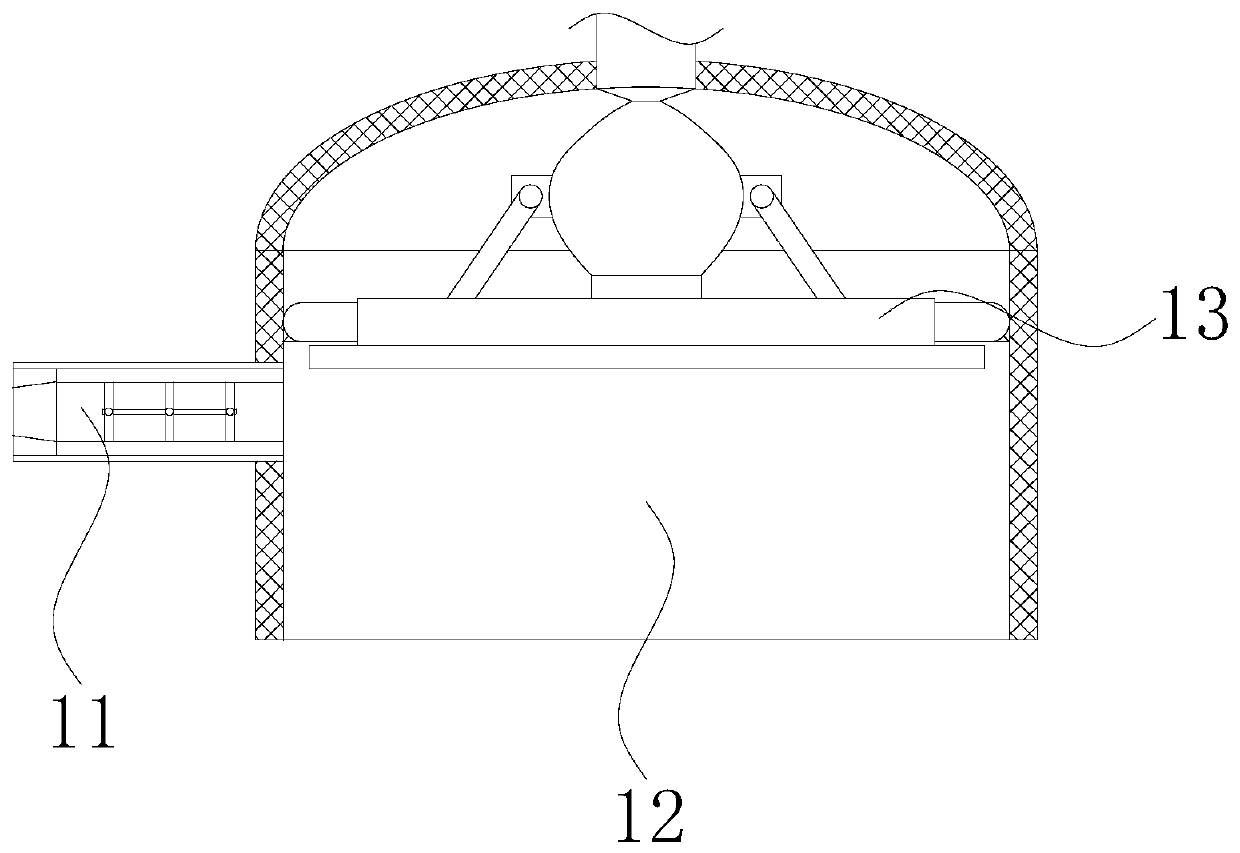

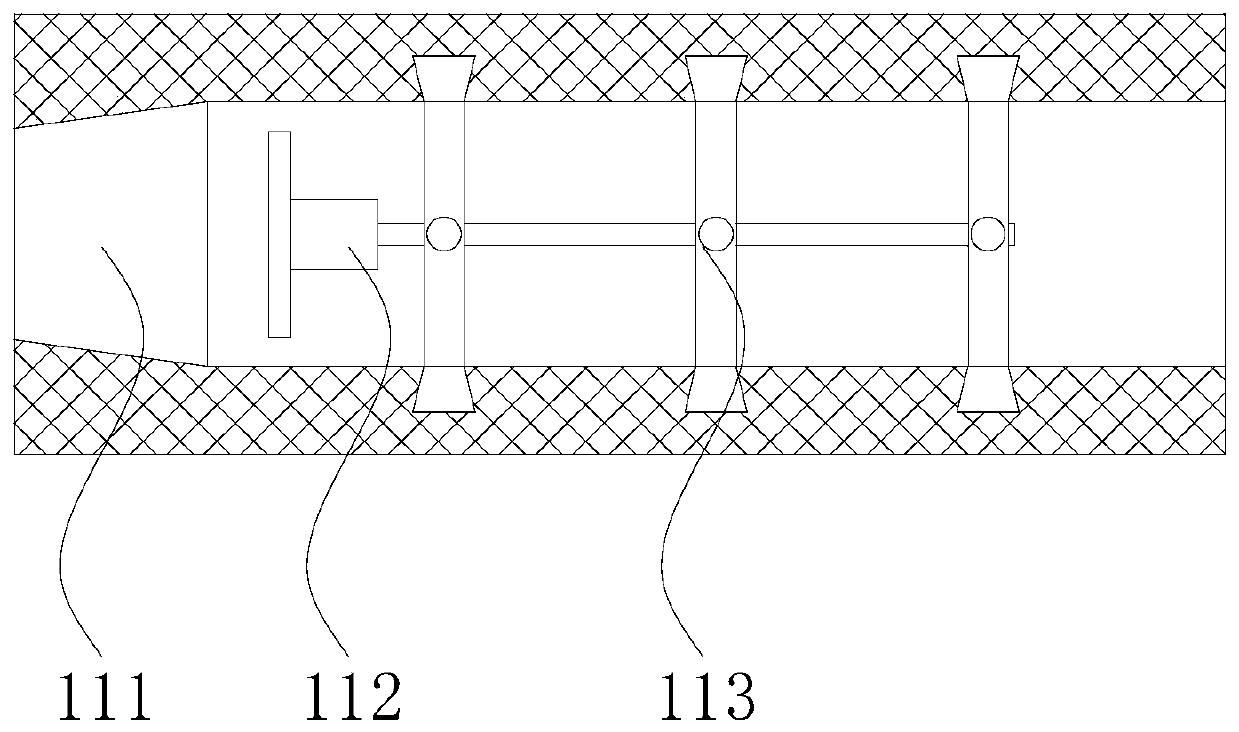

[0025] The present invention is a kind of petroleum separator, its structure comprises inlet tank 1, separation tank 2, oil outlet pipe 3, water outlet pipe 4, gas outlet pipe 5, and described inlet tank 1 is fixedly installed on the upper end of separation tank 2 and interpenetrates, and described separating The right side of the tank 2 is embedded with an oil outlet pipe 3 and communicates with each other. The bottom of the separation tank 2 is fixed with a water outlet pipe 4. The top of the inlet tank 1 is embedded with an air outlet pipe 5 and communicates with each other. The inlet tank 1 includes an oil inlet pipe 11 , tank body 12, airbag mechanism 13, the oil inlet pipe 11 is embedded in the left side of the tank body 12 and communicates with each other, the inner upper end of the tank body 12 is equipped with an airbag mechanism 13, and the upper end of the airbag mechanism 13 communicates with the air outlet ...

Embodiment 2

[0032] as attached Figure 6 to attach Figure 8 Shown:

[0033] Wherein, the air bag mechanism 13 includes an air inlet 131, an air bag 132, a push rod 133, and a scraper 134. The air inlet 131 is fixedly installed on the bottom of the air bag 132 and communicates with each other. The upper end of the air bag 132 is connected to the outlet pipe 5. Through, the airbag 132 is provided with push rods 133 on the left and right sides, the lower end of the push rod 133 is fixed to the inside of the scraper 134, the airbag 132 is an irregular hollow sphere and has a left-right symmetrical structure. Inflated, both sides of the air bag 132 push down the push rod 133, driving the scraper 134 to scrape down the thick oil adhered to the inner wall of the tank body 12.

[0034]Wherein, the scraper 134 includes a plate body 34a, a spring 34b, a fitting plate 34c, and a burr mechanism 34d. A spring 34b is fixedly installed inside the plate body 34a, and the fitting plate 34c is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com