Oil leak-proof parallel shaft helical gear reducer

A technology of parallel shaft helical gear and reducer, which is applied in gear transmission, gear lubrication/cooling, belt/chain/gear, etc. It can solve the problems of short service life of oil pump and reducer, and achieve cost saving, good lubrication effect, The effect of improving the stability of use and the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

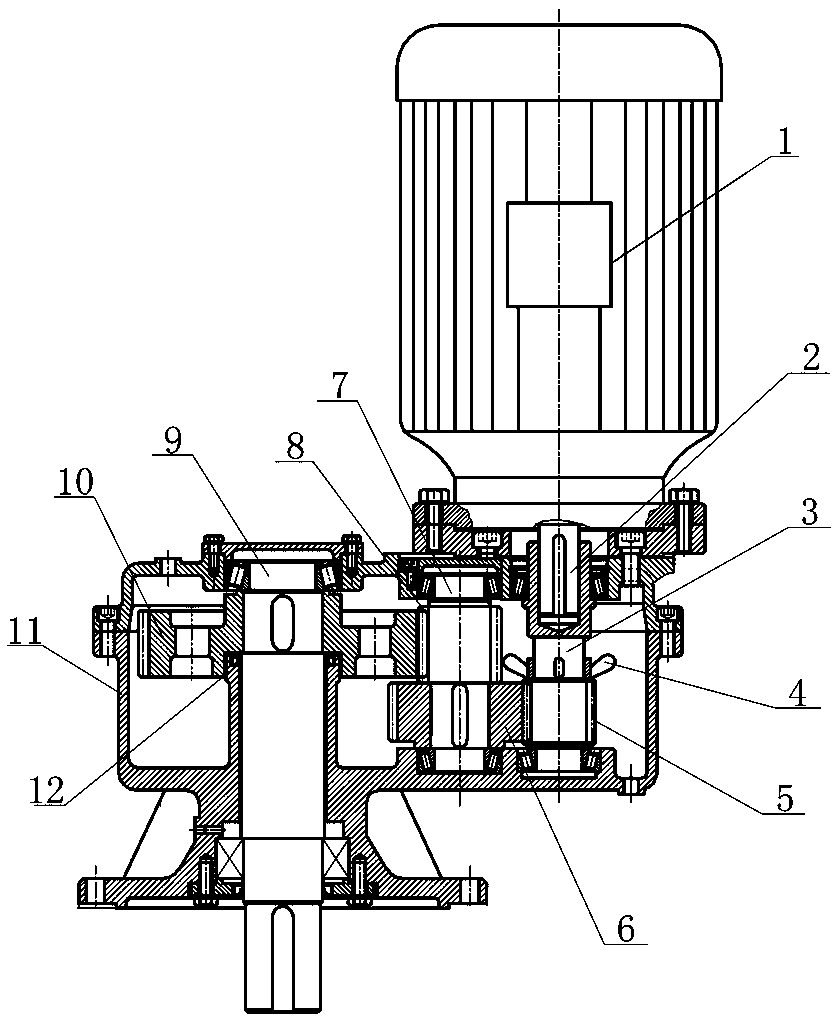

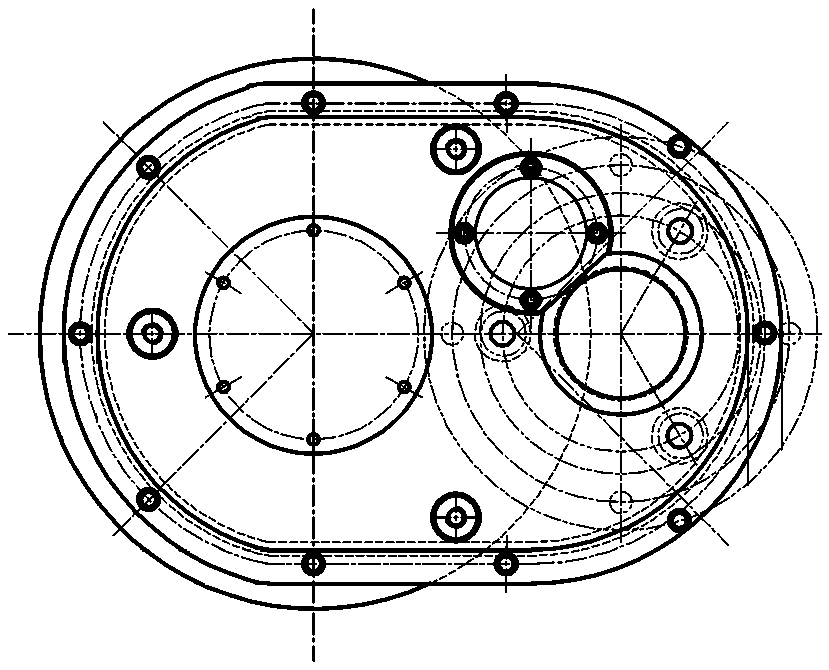

[0018] refer to Figure 1 to Figure 2 , the present invention includes a reduction box; the top of the reduction box is provided with a motor, and the transmission shaft of the motor is connected to the input shaft in the reduction box;

[0019] The input shaft is in meshing transmission connection with the first reduction gear 6 on the rotating shaft 7 through the gear I5; the rotating shaft 7 is in meshing transmission connection with the second reduction gear 10 on the output shaft 9 through the gear II8;

[0020] The rotation connection between the output shaft 9 and the reduction box body 11 is provided with an oil retaining protrusion 12; the top of the oil retaining protrusion 12 is fitted and slidably connected to the bottom surface of the second reduction gear 10;

[0021] The bottom of the input shaft 3 is provided with an oil throwing tooth piece 4 .

[0022] Further, the oil throwing gears 4 are arranged in a petal shape with the input shaft as the center.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com