Optical system for inspecting super-large-aperture concave aspheric reflector

A spherical reflector and optical system technology, which is applied in the field of optical systems for aspheric inspection, can solve the problems of difficult processing and assembly, limit the caliber of inspectable paraboloids, and long inspection optical path length, and achieve easy processing and assembly, small caliber , the effect of high-precision inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, the present invention will be further described through the description of the embodiments and the accompanying drawings.

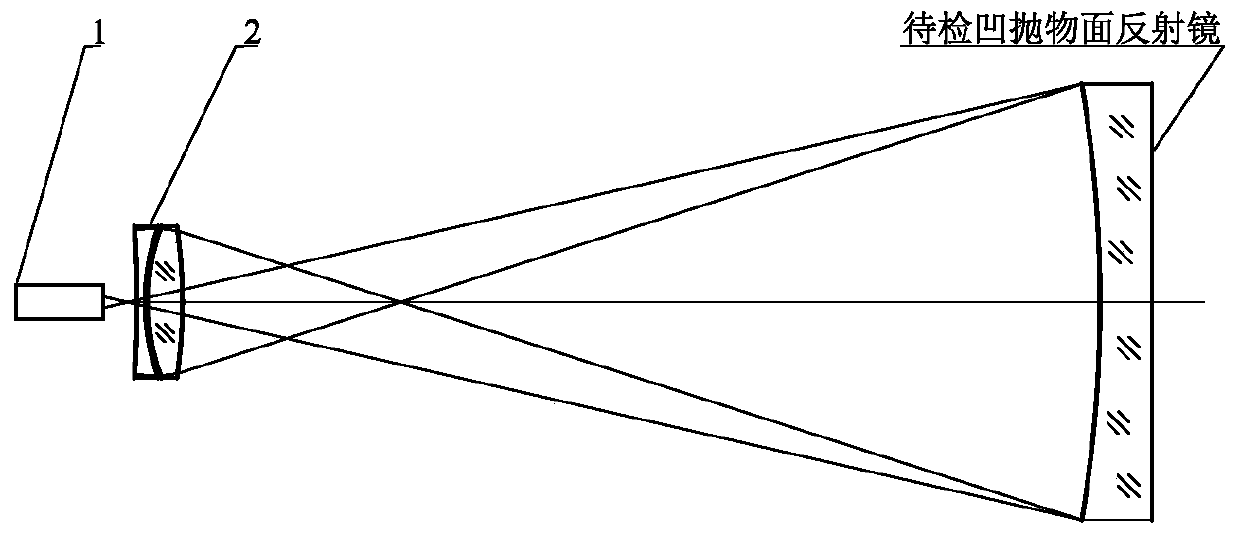

[0013] It is known that the diameter of the parabolic mirror to be inspected is 1200 mm, the relative aperture is 0.6, and the eccentricity is 1. The inspection optical path is composed of laser interferometer, self-alignment lens group and concave parabolic reflector to be inspected. The ratio of the correction lens group to the diameter of the concave parabolic reflector to be tested is 0.1.

[0014] The self-aligning lens group is located in front of the conjugate rear point of the parabolic mirror. The self-collimating lens group consists of two lenses, one negative and one positive. The incident height of the light before being reflected by the mirror to be inspected is very low on the lens group, where the lens group acts as a field mirror in the optical path. As for the optical path reflected by the mirror to be inspected, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com