A production process and cable for intelligent monitoring traction cables for high-speed railways

A technology of intelligent monitoring and production process, applied in the direction of power cable, insulated cable, cable/conductor manufacturing, etc., can solve the problems of high failure rate of 27.5kV high-voltage cable, judgement of cable operation status, etc. tide, long monitoring range and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

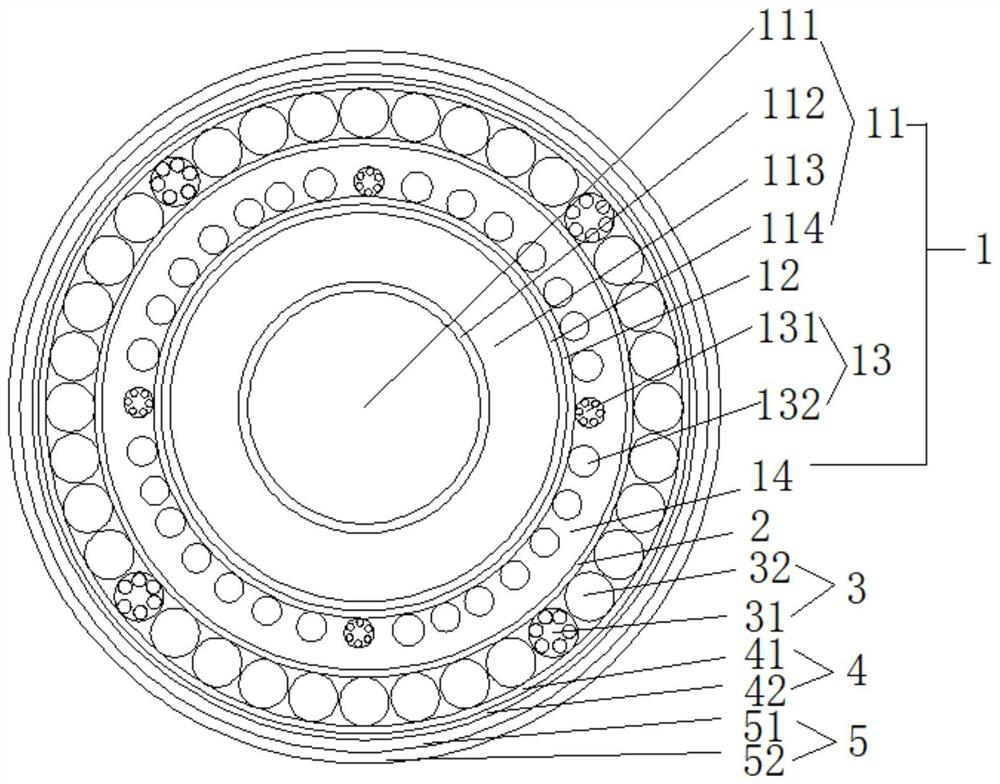

[0052] See figure 1 , an intelligent monitoring traction cable for high-speed rail in this embodiment, sequentially includes a power transmission cable core 1, a water-blocking layer 2, a non-magnetic wire protective layer 3, a water-blocking flame-retardant layer 4 and an outer sheath layer 5 from the inside to the outside ;

[0053] The power transmission cable core 1 includes an insulated wire core 11, a semiconductive resistance hose 12, a wire shielding layer 13 and an embedded waterproof layer 14 from inside to outside; the insulated wire core 11 includes conductors 111, Conductor shielding layer 112, insulating layer 113 and insulating shielding layer 114; The section of conductor 111 is 150mm 2 ~400mm 2 , the cross section of the condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com