Novel device for automatically stripping anticorrosive coating of pipeline

A technology of automatic stripping and piping, which is applied in the direction of coil devices, induction heating devices, induction heating, etc., can solve the problems of polluting the construction environment on site, low work efficiency, and slow heating speed, so as to achieve pollution-free construction environment, safe and reliable use, Fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

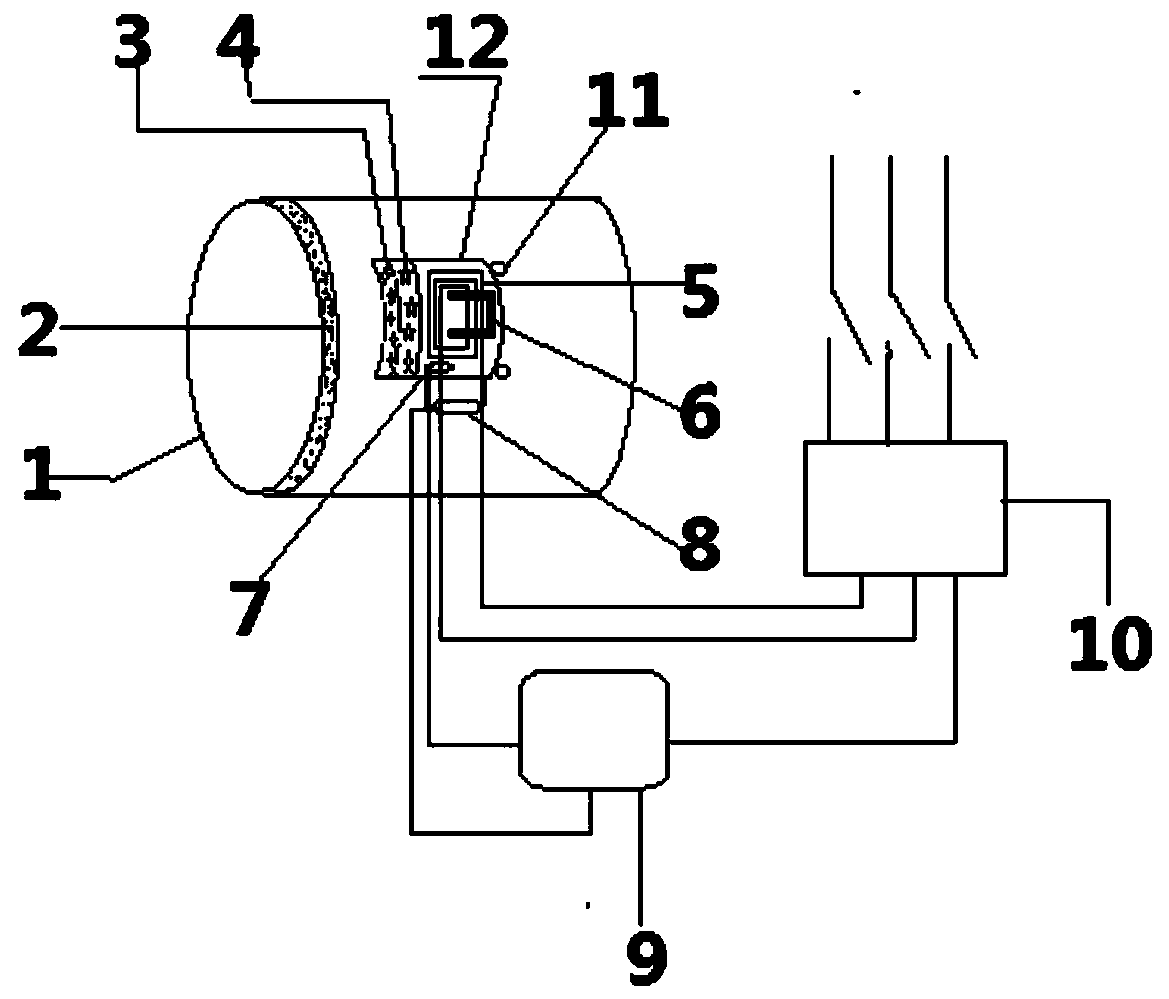

[0008] A hand-held heating device for peeling off the anticorrosion layer of pipelines. The heating coil 5 is installed on the heat insulation layer 3 on the reverse side, and the reflective magnetic plate 4 is installed on the front side. After the temperature probe 7 is installed on the flexible shell 12 and connected with the temperature controller 9, the control signal is given to the intermediate frequency heating power supply 10, the motor winding device 8 is connected to the temperature controller 9, the handle 6 is installed on the surface of the flexible shell 12, and the walking support wheel 11 Installed on both sides of the flexible shell 12 to play a supporting role. The working principle of the present invention is to output 30Khz intermediate frequency electricity to the heating coil 1 through the intermediate frequency heating power supply 10, and the intermediate frequency electricity passes through the heating coil 4 to form a magnetic field and then penetrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com