A dust-removing device for crushing and recycling concrete waste blocks

A technology for concrete waste, recycling and processing, applied in grain processing, combination devices, separation methods, etc., can solve problems such as health hazards of workers and poor dust removal effect of recycling and processing devices, and achieve improved user experience, rich functions, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

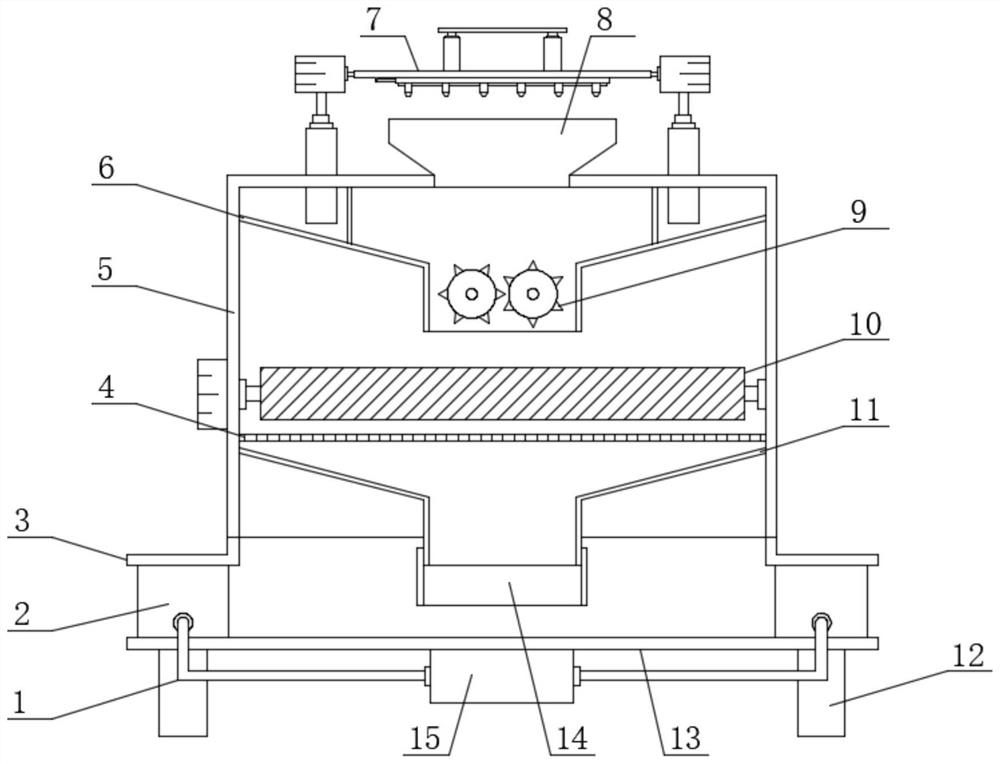

[0020] see Figure 1-Figure 3 , the present invention provides a technical solution: a dust-removing concrete waste block crushing recovery treatment device, including a crushing box 5, a feeding hopper 8 is arranged in the middle of the upper surface of the crushing box 5, and a first guide is arranged at the top of the crushing box 5. The flow member 6, the bottom end of the first flow guide member 6 is provided with a first pulverizing roller 9, the bottom of the first flow guide member 6 is provided with a second flow guide member 11, and the top of the second flow guide member 11 is provided with a filter screen 4. The top of the filter screen 4 is provided with a second crushing roller 10, and the use of the first flow guide 6, the second flow guide 11, the first crushing roller 9 and the second crushing roller 10 is the prior art, and the crushing box 5 is provided with a dust removal mechanism 7;

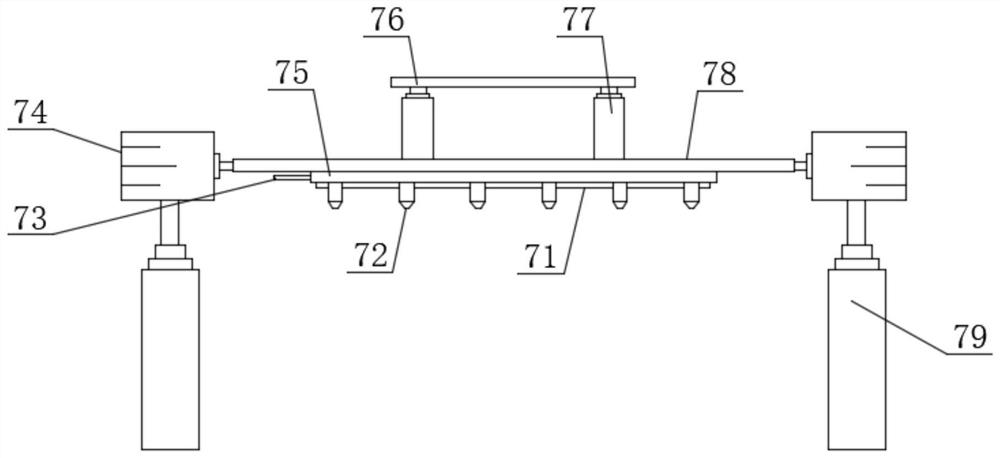

[0021] The dust removal mechanism 7 includes a second support plate 78...

Embodiment 2

[0028] On the basis of Embodiment 1, in order to make the use of the recycling device more reliable, in this embodiment, preferably, the two ends of the lower surface of the first support plate 13 are provided with support feet 12, and the support feet 12 are cuboid structures;

[0029] In order to make the shock absorption effect of the supporting feet 12 better, in the present embodiment, preferably, the material of the supporting feet 12 is rubber, and the top of the supporting feet 12 is fixedly connected with the first supporting plate 13 by bolts, and the supporting feet 12 play a role in reducing shock absorption. Shock and support function, so that the use of recovery processing device is more reliable;

[0030] In order to make the shock-absorbing effect of the shock-absorbing airbag 2 better, in this embodiment, preferably, an air pump 15 is provided in the middle of the lower surface of the first support plate 13, and an air pump 15 is provided at the output end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com