A workpiece rotating device for laser engraving based on the field of laser and optical communication

A laser engraving and rotating device technology, which is applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as low processing precision, inability to realize rapid adjustment and automatic locking of the adjustment structure, and inability to ensure uniform tightening force, etc. , to achieve the effect of improving the regulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

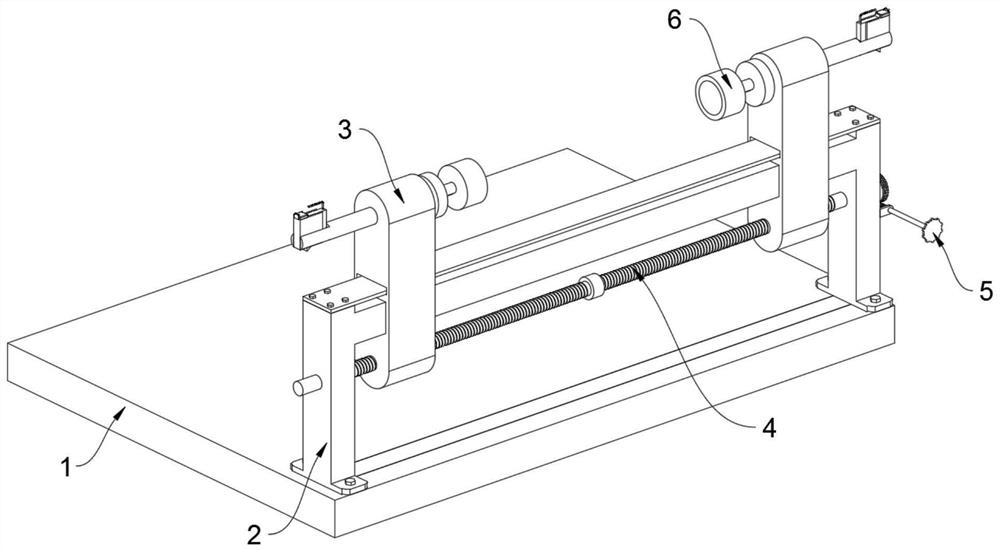

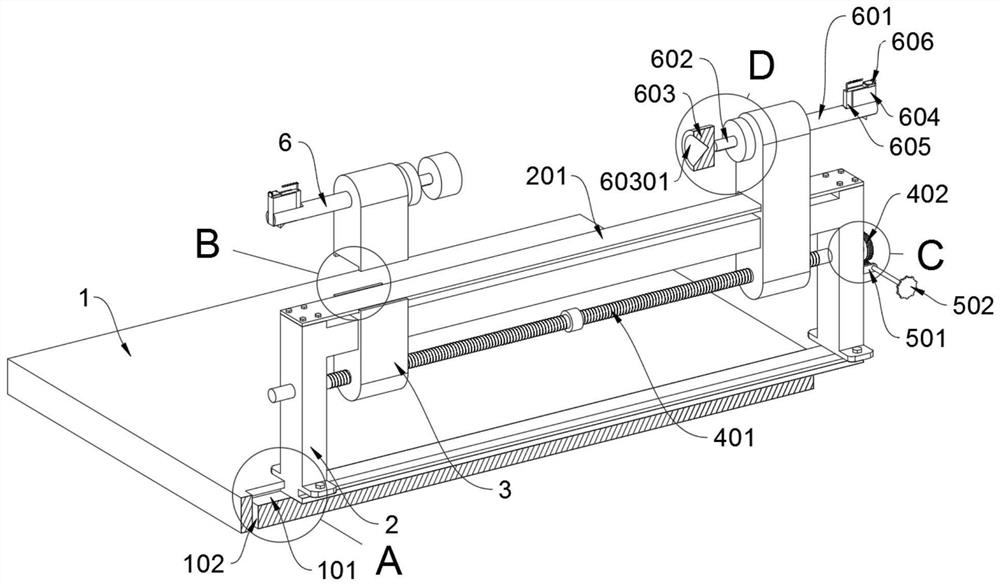

[0035] as attached figure 1 to attach Figure 9 Shown:

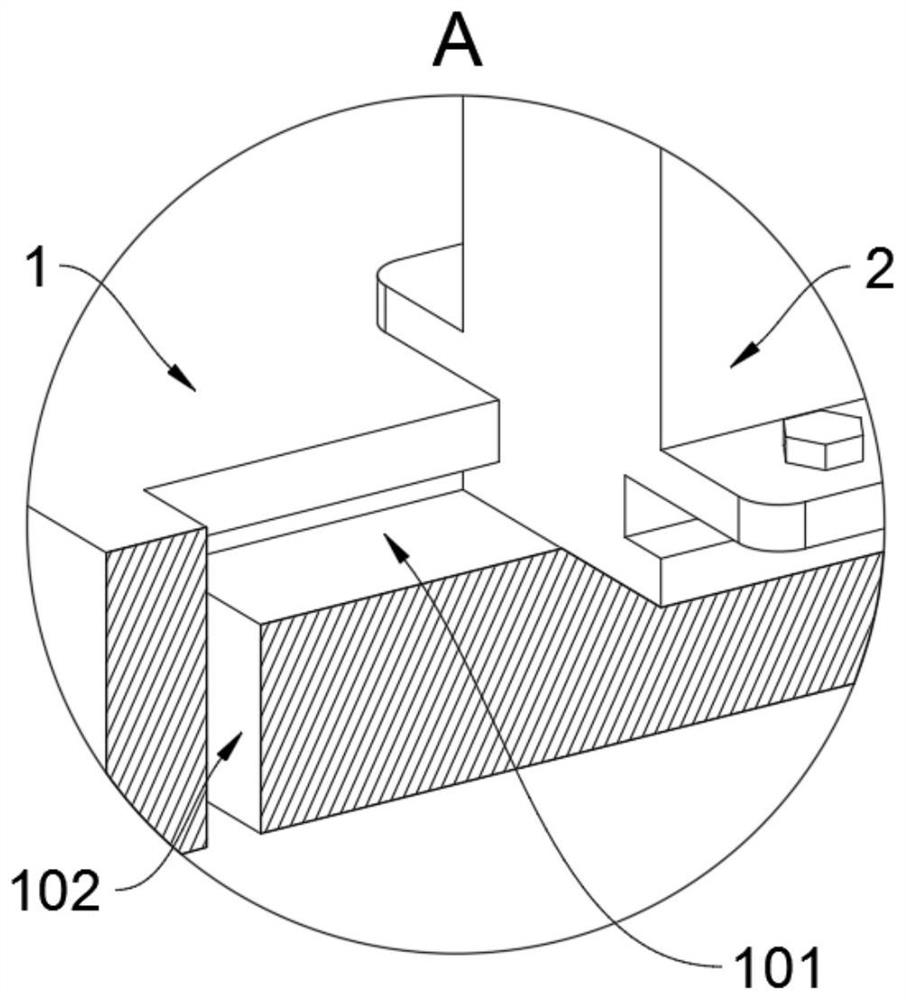

[0036] The invention provides a workpiece rotating device for laser engraving based on the field of laser and optical communication, which includes a base 1; a sliding seat 2 is fixedly connected to the base 1, and two adjustment seats 3 are slidably connected to the sliding seat 2, and each A fixed structure 6 is rotatably connected to each adjustment seat 3; refer to as figure 2 , the sliding seat 2 is a concave frame structure, and the top surface of the sliding seat 2 is fixedly connected with a baffle 201 by bolts; the adjusting seat 3 includes a rectangular hole A301, and the adjusting seat 3 is provided with a rectangular hole A301, and the adjusting seat 3 Sliding connection with the sliding seat 2 through the rectangular hole A301; the top beam part of the sliding seat 2 is a sliding track, and the baffle plate 201 forms the protective structure of the beam part of the sliding seat 2. The setting of the baffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com