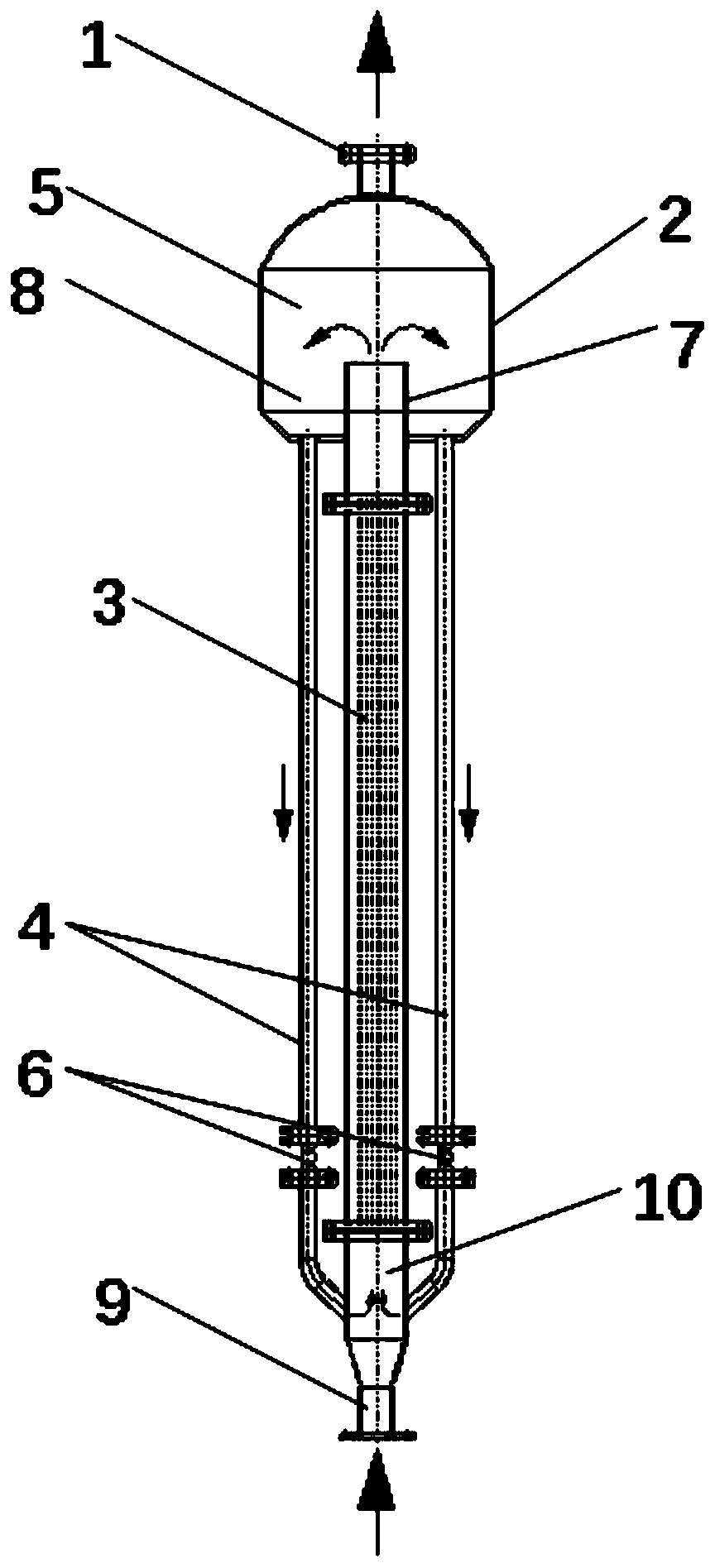

Self-cleaning heat exchanger

A heat exchanger and self-cleaning technology, applied in the direction of heat exchanger type, indirect heat exchanger, heat transfer modification, etc., can solve the problems of heat exchanger scaling, circulation difficulty, solid particle separation, etc. The effect of cleaning, enhancing heat transfer and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

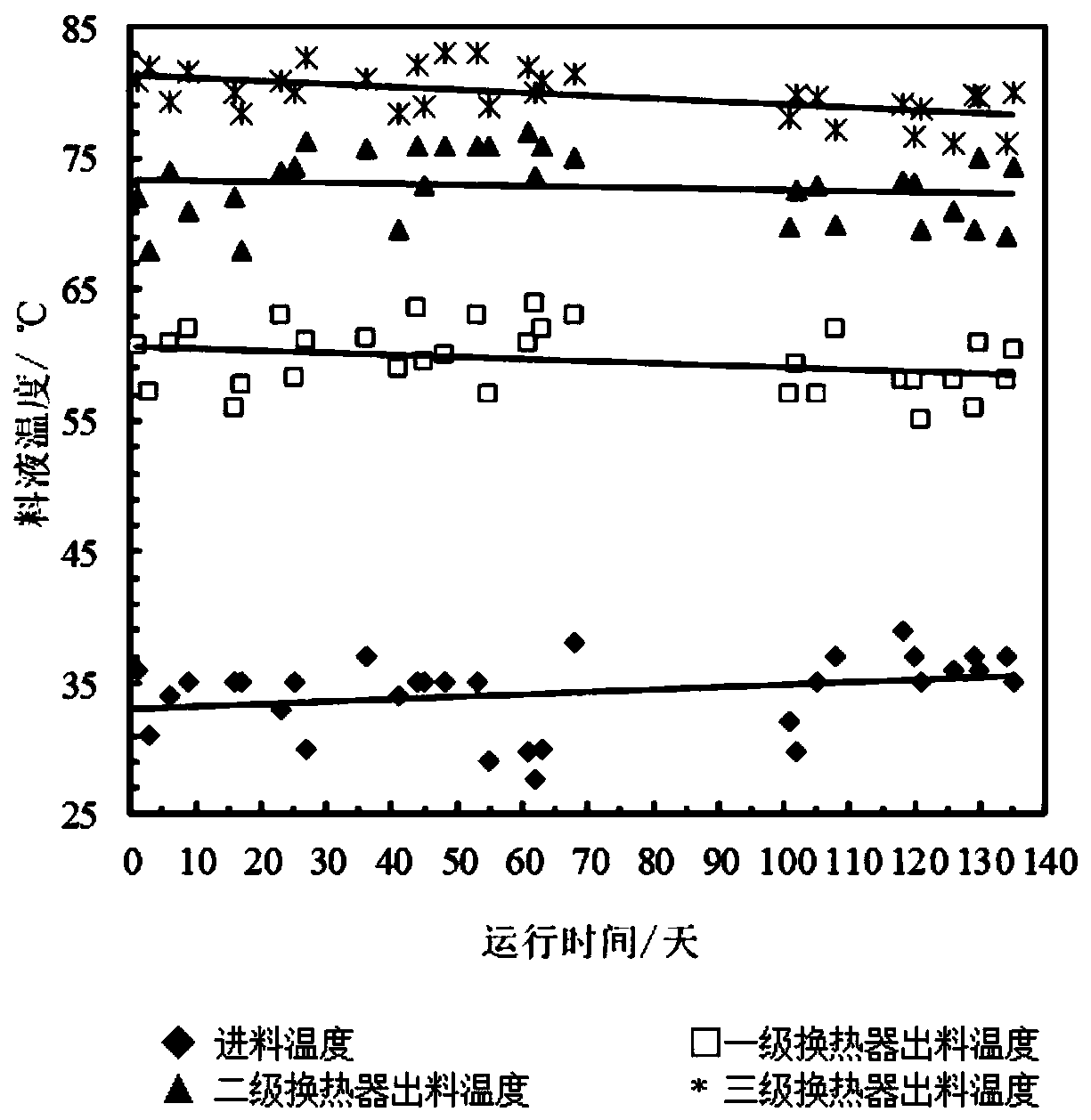

[0044] The self-cleaning heat exchanger described in the patent of the present invention is used to preheat a certain high-hardness brine, and three heat exchangers are operated in series. The monitoring results of the temperature of the fluid at the inlet and outlet of the heat exchanger are as follows figure 2 As shown, it can be seen that when the new heat exchanger runs continuously for 135 days, the outlet temperature of the feed liquid brine basically does not decrease significantly, and the outlet temperature of the preheated brine can fully meet the production process requirements and can be continuously produced. Before the new technology was adopted, when the preheater was running for 30 to 40 days, due to serious fouling, the outlet temperature of the preheated brine dropped significantly, which could not meet the requirements of the production process. The preheater had to be stopped for mechanical cleaning. Heater took more than 3 days. The comparison results sho...

Embodiment example 2

[0046] The self-cleaning heat exchanger described in the patent of the present invention is used to heat the gypsum-type mine brine required by a 300,000-ton / year vacuum evaporation salt production line. It has been proved by long-term continuous operation that the fluidization of solid particles inside the heat exchanger, The circulation and flow are relatively stable, and the equipment is easy to operate and control; the self-cleaning heat exchanger described in the present invention can fully achieve the purpose of scale prevention, descaling and enhanced heat transfer of the gypsum-type mine brine heat exchanger, and can be produced continuously without the need for Stop the vehicle to descale and clean the heat exchanger. By comparing the output statistics, after adopting the heat exchanger of the present invention, under the same condition of steam consumption, the daily increase in output is about 100 tons, that is, the output is increased by about 10%, and there is abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com