Optical fiber pressure sensor based on soft silicon diaphragm and detection method thereof

A technology of pressure sensor and silicon diaphragm, which is applied in the direction of fluid pressure measurement by optical method, measurement of fluid pressure, and measurement of the change force of optical properties of the material when it is stressed, which can solve the problem of complex film making methods and low cost. High and demanding problems, to achieve the effect of improving detection efficiency and accuracy, reducing production costs and time, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

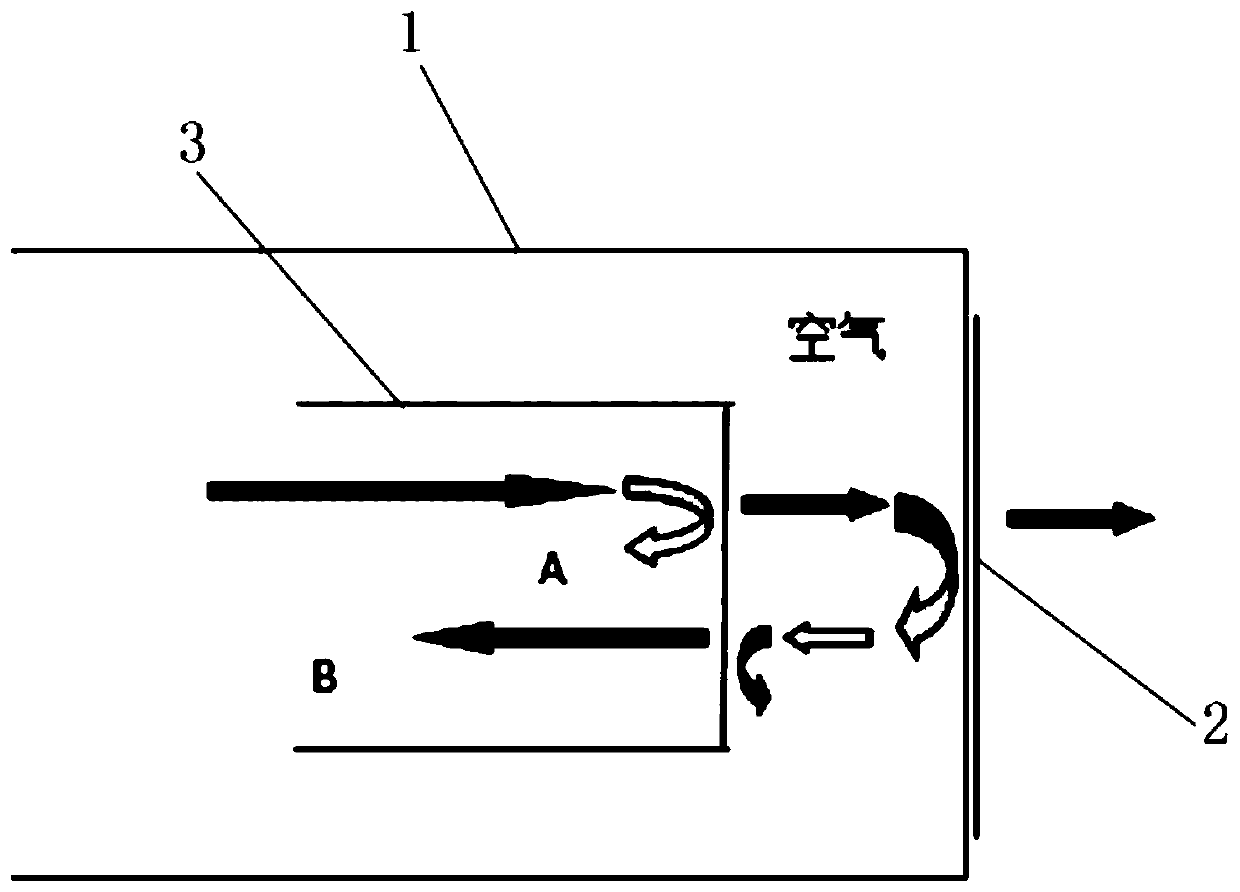

[0042] A soft silicon diaphragm 2 made of silica gel such as AB silica gel is glued in the optical path formed by the input optical fiber, such as a nozzle, and the optical fiber 3 is placed close to the soft silicon diaphragm 2 to detect its deformation. Furthermore, the principle of the present invention is to use the principle of light interference, because the reflectivity of light in different media is different, so light will be reflected when passing through the air and the soft silicon diaphragm, and the two beams of light reflected back to the system will generate put one's oar in. Specifically, when the light reaches the mouth of the optical fiber, a reflected light A will also be formed. When the light emitted by the laser passes through the optical fiber 3 and then passes through the air to reach the surface of the soft silicon diaphragm, a reflected light B will be generated. The FP cavity is formed between the films, and finally the reflected light A and the refl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com